Printing businesses are turning to 3D-textured UV printing as a differentiator in a competitive market. UV technology offers the unique ability to produce raised, tactile textures. For businesses exploring UV printing, it’s essential to understand this distinctive capability. Some UV printers can produce multi-layered effects directly onto substrates.

For those already experienced in UV, adopting 3D-textured UV printing is a strategic move. It enhances product value and can drive up-selling opportunities. It can also position your business at the forefront of commercial printing.

For even more creative possibilities, explore second-surface printing with a flatbed UV printer. This technique prints on the reverse side of clear materials like acrylic or glass, protecting the design while creating a striking depth effect. Learn how this method adds durability and sophistication to signage, awards, and displays in this detailed guide from ColDesi. Read More.

What Sets 3D-Textured UV Printing Apart

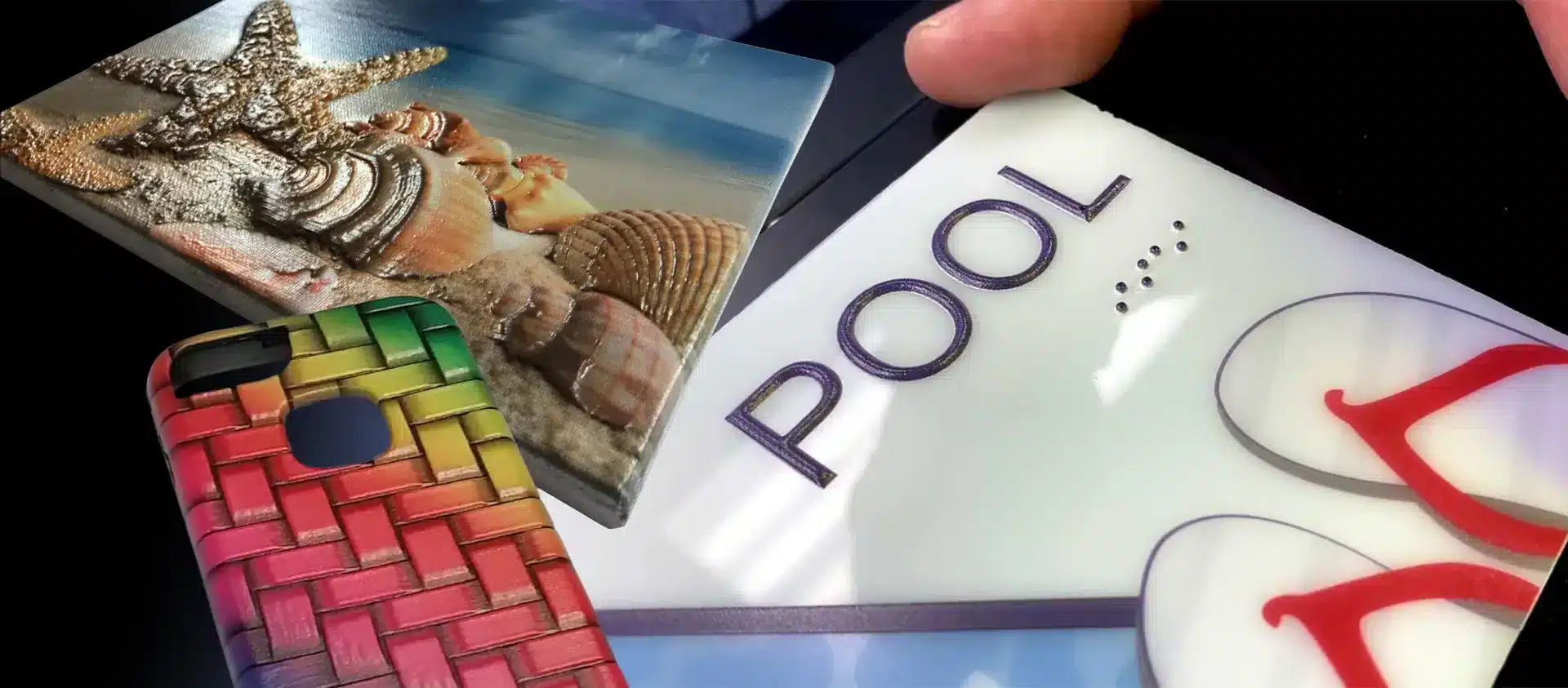

3D-textured UV printing adds a new layer of capability to UV printers. It allows you to create raised, layered, and tactile surfaces. Using RIP software, accurate printhead control, and UV ink layering, you can print textures with depth—even Braille lettering. These effects work on both rigid and flexible materials. Textured UV printing adds both visual impact and functional value. It gives signage, packaging, and promotional products a more dynamic finish. Adding texture offers an edge in product quality, customer appeal, and market differentiation.

Where Texture Makes the Difference

Across many verticals, UV printing with texture creates tangible value:

- Signage: Braille signs, raised-letter directories, architectural décor, and wall art are all enhanced with tactile texture for improved accessibility and visual impact.

- Packaging: Brands are adopting spot UV texture and embossed UV printing on cartons and labels to convey exclusivity and elevate shelf appeal.

- Promotional Products: From phone cases to personalized awards, raised UV printing adds sensory interest that commands attention.

- Retail Displays: Multi-dimensional textures invite interaction, especially in POP displays and interior signage.

These examples highlight how texture UV printing turns functional prints into premium experiences.

Tactile Texture as a Sales Differentiator

What’s the real value of touch? In a visual-dominated industry, tactile texture is a channel of communication: physical engagement.

When customers see a raised design or feel a textured logo, it triggers an emotional reaction. Flat prints don’t have the same impact. This perceived quality leads to:

- Higher product pricing

- Longer engagement times

- Greater brand retention

- More effective upselling of premium print services

The Mechanics Behind 3D-Texture UV Printing

Here is how 3D-textured UV printing delivers layered results:

- Multi-Pass Printing: UV-curable ink is applied in multiple passes. This builds up layers to form textures with different heights.

- Gloss/Varnish Layering: Gloss varnish can be added selectively. It goes on top of inks or directly on the material to highlight areas and create contrast.

- CAD & Artwork Effects: Vector paths, bitmap textures, and grayscale depth maps are used. These control texture height, direction, and detail precisely.

These tools make raised-texture UV printing both decorative and practical. For example, they can create anti-slip areas or tactile warnings.

Customization and Branding Power

- Variable Data Printing becomes more dynamic. Printers can personalize both the look and feel of each piece.

- Short-Run Packaging stands out. Brands can assess raised label designs before going into full production.

- Custom Awards & Décor get a luxury finish. The added texture boosts perceived value.

Tactile Effects Meet Personalization Trends

In retail, signage, and promotional markets, personalization isn’t optional—it’s expected. Textured UV printing takes it further. It adds a personalized feel. That tactile element creates a deeper, more memorable connection.

- A realtor’s textured welcome plaque

- A textured retail display that mimics woodgrain or stone

- A school award with layered metallic print and tactile depth

These examples tap into consumer psychology, creating richer customer experiences and driving loyalty. Combined with digital workflows, UV printing with texture supports scalable, high-profit personalization services.

Tangible Gains from Textured UV

The return on investment for raised UV printing is clear:

- Higher Margins: Textured finishes command premium pricing.

- Value Perception: Clients view textured products as higher quality.

- Long-Term Contracts: Tactile signage and packaging often lead to repeated orders.

- Less Competition: Not all shops offer embossed UV printing, giving adopters an edge.

Trends, Materials, and Innovation

As we move through 2025 and beyond, 3D- textured UV printing is gaining traction across:

- Textured Decals: Automotive, marine, and wall graphics that add grit, grain, or relief.

- Braille & Compliance Signage: Required in public buildings and institutions.

- Luxury Print Design: Invitations, packaging, and limited-edition prints with tactile branding.

- Art & Decor Prints: Replicating canvas brushstrokes, woodgrain, and embossed accents.

Textured UV Is the Next Competitive Advantage

For business owners, 3D-textured UV printing is more than a feature. It opens doors to new markets, higher margins, and creative freedom.

For more information fill out the form below or call 877-793-3278.