What Should you Look for in a Heat Press?

If you’re in the customization business – or starting one – chances are you will need a Heat Press.

A good quality heat press is vital when it comes to transferring printed images onto all sorts of goods. So here’s a list of things you should look for when you consider your heat-press options.

Note: Hobbyists will need to make a few adjustments to this list. Partly because if you’re using a heat press only occasionally (say to make shirts with your Cricut cutter or Silhouette), then you’re probably not in it for profit – and that will impact your budget.

And if you’re only an occasional user, you don’t need something that’s made for regular, daily commercial use.

Our list below includes optional features and the basics, but each is important enough to inform your purchase.

Heat Press Options and Styles

Platen Size

The platen is the lower table part of the heat press that you lay your garment and transfer on.

Platen sizes start as small as 4” and work their way up past the most popular size of 25” x 25”. The most commonly recommended for custom apparel – a flat press – is 16” x 20”. That will allow you to print any transfers or image size that you’re likely to need.

Most heat presses have a fixed platen size, but some like the Hotronix Fusion IQ and some by GeoKnight have swappable platens, so you can change sizes.

Manual vs. Automatic

Usually, these terms refer to how you open and close the press.

A manually operated press is one that you have to open and close with your hands.

And then, an automatic press has a timer on it that will open it when the timer goes off.

Each type of apparel decorating process has a different recommended temperature and timing. Leaving it on too long is just like leaving your home iron on a shirt for too long!

Example: for DTG printing, we recommend the DK20A because it’s an automatic press or “auto pop-up.” That way, if we don’t hear the timer go off, the shirt won’t be scorched.

BUT for DigitalHeat FX transfer making, we don’t recommend a clamshell, auto pop heat press because that motion may damage the transfer.

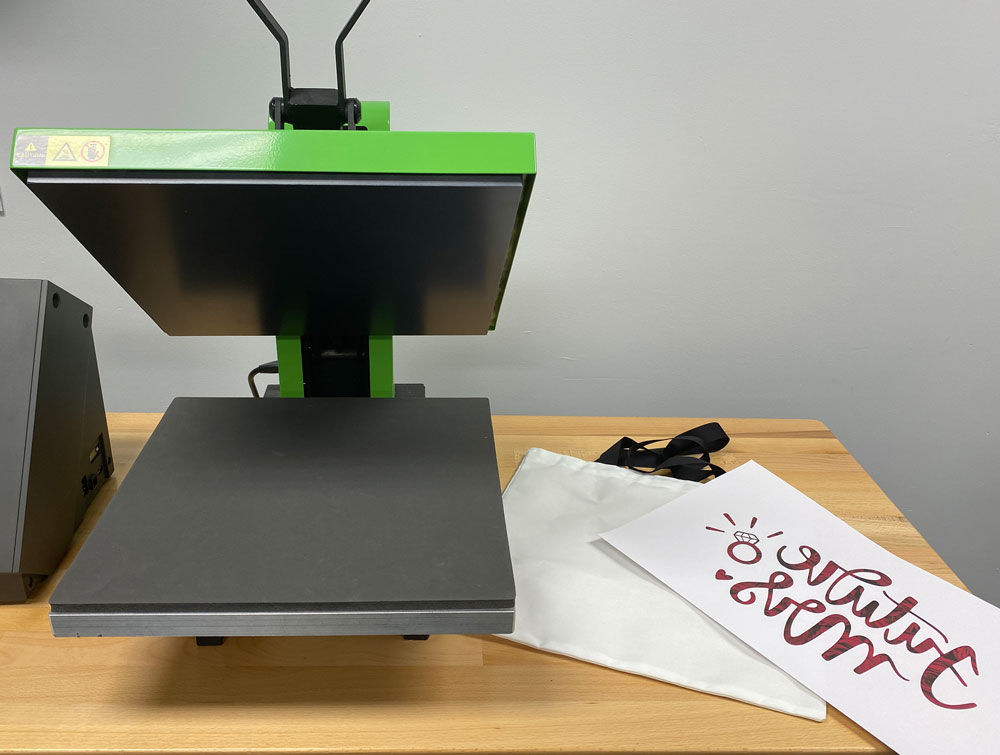

Clamshell vs. Swing Away

A clamshell press opens UP, with the top half of the press coming down like a clam’s shell.

The swing-away heat press has a top that raises straight up slightly, then swings out of the way horizontally to allow you to remove the current garment and add the next.

The swing-away exposes less of the hot surface, making it safer to operate, and provides the most even pressure possible since it comes straight down onto the platen below.

Typically, the swing away is also easier on the body because you don’t have to reach up as high as you do for the top of the clamshell press to activate.

A good example of a swing-away heat press can be found here.

Air Operated Presses

If you’re printing custom shirts or making promotional products in a busy shop – hundreds a day- that can take a toll on the operator.

Higher-end heat presses are often pneumatic, with air pressure being used to lift up and move the top half of the heat press. That feature is activated by buttons on the press or a handy foot pedal.

It makes for more automation and less manual effort. However, pneumatic presses are more expensive and require a source of compressed air so that you won’t find these in every pro shop.

The most popular air operated press is the Hotronix Air Fusion found here.

Commercial Heat Press Features

You may be expecting these to be the fancy “self-parking” level features found in consumer goods. But what you’re really looking for is the quality of equipment.

Temperature Accuracy

If you’re making t-shirt transfers with a white toner printer, applying a screen print transfer, or even curing a DTG printed shirt, you’ll notice that each one comes with a temperature requirement.

A heat press that runs hotter than where you set it can scorch a shirt and ruin a transfer.

One that runs cold can cause a failed application. Or worse, it LOOKS fine but washes off because the glue wasn’t set correctly.

The temperature must be measured across the entire surface. And it needs to be the SAME temperature at the center as it is on the edges.

Pressure Accuracy

Pressure can be essential depending on your product, especially for rhinestones, white toner printer transfers, and spangles.

A commercial heat press for t-shirts needs to produce accurate and consistent pressure to produce consistently good results.

Pressure accuracy is the hallmark of an excellent professional heat press! It’s the thing that sets the best apart from the rest.

Both Pressure and Temperature accuracy are where you’ll see a big difference between a professional heat press and a consumer one.

Have you ever applied heat transfer vinyl with a home iron? Or maybe a craft press you bought on Amazon and had the edges peel up? That’s the difference!

Durability

Your heat press will get used in a very physical way throughout each day, so the construction MUST hold up.

When you make 20 DTG shirts, for example, you’ll open and close the George Knight DK20 heat press up to 60 times. -Once to get the wrinkles and moisture out. Ones to cure the pretreat. And one to cure the shirt after it’s printed.

Imagine doing orders of 20, 30, or 50 shirts every day! That’s a lot of mechanical stress.

If you are used to working with a consumer heat-press, you’ll quickly notice the difference.

Warranty and Support

ColDesi, a distributor of Geo Knight, Hotronix, Colman, and Galaxy heat presses, only offers high-quality heat presses that do come with a warranty.

A good manufacturer stands by their products – and all the heat presses you’ll find referenced here come with a great warranty.

Overall, each heat press features state-of-the-art control systems, a heavy-duty solid steel framework, and industry-leading innovation.

Specialty Application Heat Press Options

Hats, plates, shirt labels and tags. You’d be surprised at the number of different options for specialty presses!

Here are the most common:

Galaxy Sublimation Mug Heat Press

The Galaxy Mug Pro is the ideal machine for your sublimation needs. This durable mug press features an LCD touchscreen, allowing you to adjust settings like time and temperature.

The Mug Pro GS-202 includes an 11 oz Durham heating element attached but can be easily interchanged with different sized elements if desired. The die-cast heat plate comes with a lifetime guarantee, ensuring reliability press after press.

Galaxy 15” Heat Press (Best smaller format)

This Galaxy 15X15 Heat Press is a great for any entry level business or home hobbyist. The heatable area is 15" X 15", a step up in size from the Craft Press 9X12. This makes it the perfect size for pressing your shirts, pillow cases, towels, and t-shirt designs. Larger heat platen = larger designs. This Press is the right size for most applications.

Hotronix FusionIQ 360 Cap Press

Hotronix Sports Ball Press

Customize and personalize a variety of sports balls. Use for team logos, school names, sponsor logos, corporate logos, player names/numbers, and event names

Shirt Tag Platen for FusionIQ

The Tag Along HP Platen, brought to you by a patented Livingston Systems, now lets you apply a tag and a t-shirt design at the same time. Just thread your garment onto the platen and apply your tag and full front design. Compatable with some Hotronix 16″ x 20″ heat presses.

Must Have Heat Press Option Accessories

Watch video to see the platens we carry for Hotronix Fusion Heat Press.