Second surface printing is a cutting-edge printing method. It involves printing designs on the underside (or reverse side) of a transparent substrate.

Substrates such as acrylic, glass, or polycarbonate are often used for second surface printing. This technique creates a striking, polished appearance while also protecting the printed image from wear and environmental factors. UV printers have made second surface printing more accessible and profitable for businesses.

What is Second Surface Printing?

Second surface printing is the process of printing a design or text onto the underside of a transparent material. The printed design is viewed from the unprinted side, creating depth and vibrancy that traditional surface printing cannot achieve. This technique is often used in:

- High-end signage

- Retail displays

- Architectural elements

- Decorative panels

- Backlit applications

What Are the Differences Between First Surface and Second Surface Printing?

First Surface UV Printing:

- Printing Side: The ink is applied directly to the top (front-facing) surface of the substrate.

- Viewing Angle: The design is viewed from the same side as where the ink is applied.

- Applications: Commonly used for signage, displays, and flat graphics.

- Printing Side: The ink is printed on the underside of a transparent substrate, such as acrylic, glass, or polycarbonate.

- Viewing Angle: The design is viewed through the material from the opposite side of the ink application.

- Applications: Used for signage, panels, awards, and backlit displays, where durability and a premium look are important.

First surface printing is straightforward and ideal for applications where ease of production is a priority. Second surface printing offers enhanced durability and a premium aesthetic.

How Does Second Surface Printing Work?

Second surface printing involves specialized equipment and techniques to produce high-quality, durable results. The process begins with the material selection. Transparent materials, such as acrylic or glass, are commonly chosen for their clarity.

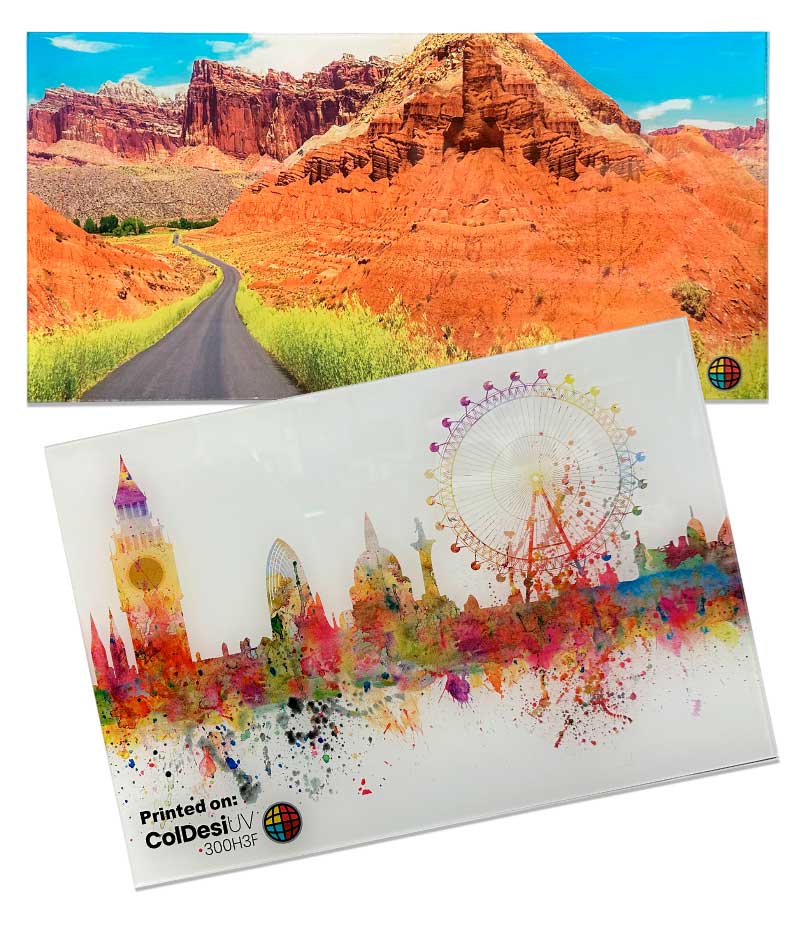

A flatbed UV printer, like ColDesi’s 300H3F or 500H3F, is set up for reverse printing. This setup includes flipping the artwork horizontally to ensure proper orientation when viewed from the unprinted side of the material.

The UV printer applies layers of ink directly onto the substrate. To enhance opacity and color vibrancy, a layer of white ink is often applied as a backing.

Finally, UV lights cure the ink instantly, resulting in a durable and vibrant print. The outcome is a professional-grade product with exceptional durability and aesthetic appeal.

What are the Advantages of Second Surface Printing?

- Durability: The printed side is protected from scratches, UV exposure, and environmental damage.

- Enhanced Visuals: Creates a polished, high-end look with depth and vibrancy.

- Versatility: Suitable for various applications, from retail to architecture.

- Weather Resistance: Ideal for outdoor use due to its durability.

Why Use a Flatbed UV Printer for Second Surface Printing?

Flatbed UV printers are the perfect choice for second surface printing, featuring unmatched versatility and precision. They are also capable of working with a variety of substrates.

ColDesi’s flatbed UV printers offer significant advantages for achieving high-quality results. They enable direct-to-substrate printing, allowing designs to be printed directly onto materials like acrylic, glass, or polycarbonate, without requiring extra steps. Their advanced printheads and software deliver high precision, ensuring consistent and detailed outputs.

The printers also feature white ink capabilities, which are crucial for producing opaque prints on transparent materials. The UV inks enhance durability, offering weatherproof, scratch-resistant, and fade-resistant prints.

By accommodating materials of varying sizes and thicknesses, ColDesi’s flatbed UV printers are ideal for both small-scale and large-scale projects, making them a versatile solution for professional-grade second surface printing.

How Can Second Surface Printing Help Grow My Business?

-

Diversified Services: Offer high-end signage, retail displays, and decorative panels to appeal to new markets.

-

Higher Profit Margins: Premium products command higher prices, boosting profitability.

-

Customer Retention: Provide unique solutions that set your business apart from competitors.

-

Scalability: Manage both small custom orders and high-volume production runs.

-

Market Demand: As businesses seek innovative branding solutions, second surface printing is increasingly in demand.

What Substrates Can Be Used for Second Surface Printing?

Flatbed UV printers are capable of printing on a variety of transparent substrates, making them highly versatile for second surface printing applications.

Common materials include acrylic, valued for its durability and clarity, making it a popular choice for signage and displays. Quick to cure, UV on Glass is another common option, often used for architectural elements and upscale decorative pieces. Polycarbonate is lightweight and shatter-resistant, making it ideal for industrial and retail applications.

ColDesi’s flatbed UV printers are engineered to work seamlessly with these materials, providing the precision needed to create high-quality prints. This capability enables businesses to explore a wide range of creative possibilities.

Do I Need Special Inks for Second Surface Printing?

Yes, the quality of ink plays a critical role in second surface printing. UV-curable inks are essential for this method because they:

- Cure Instantly: Preventing smudging or bleeding during printing.

- Offer High Adhesion: Bond effectively to smooth surfaces like glass and acrylic.

- Provide Vibrant Colors: Ensure clarity and vibrancy when viewed from the unprinted side.

ColDesi’s UV printers use VividBond UV Ink Technology. VividBond is formulated for superior adhesion and durability on a wide range of substrates.

How Does White Ink Play a Role in Second Surface Printing?

White ink plays a critical role in second surface printing. Since the design is printed on the reverse side of the material, white ink serves as a base layer beneath the color design. This white layer effectively enhances the opacity and vibrancy of the design. Without it, colors may appear translucent or muted.

The white ink acts as a “backing” for the artwork, ensuring that the colors stand out and maintain their intended brightness when viewed. This backing layer is crucial for creating sharp, professional-grade prints. The white layer prevents light from passing through the design, acting as a barrier that improves both its visibility and durability.

ColDesi’s flatbed UV printers have advanced white ink capabilities, allowing for precise application and customization of this critical layer. These features ensure that the final output meets the highest standards of quality.

What File Preparation is Required for Second Surface Printing?

Proper file preparation is essential for the best results in second surface printing. The first step is to reverse the artwork horizontally. This ensures the design displays correctly when viewed from the unprinted side of the substrate.

Accurate color management is also critical. This involves using high-resolution files and calibrating colors to maintain precision and vibrancy. To enhance the opacity and vibrancy of the print, a white ink layer should be added beneath the design. Files should be saved in high-quality formats, such as PDF or EPS, to ensure compatibility and preserve image integrity with the printer’s software.

ColDesi’s UV printers have intuitive software that streamlines the file preparation process, making it easier to achieve consistent and professional results.

How Do I Maintain the Quality of My Prints?

- Regular Cleaning: Prevent ink buildup on printheads and other components.

- Ink Monitoring: Use only high-quality UV inks, such as those from ColDesi.

- Calibration: Regularly calibrate the printer to maintain precision.

- Proper Storage: Store substrates in a clean, dust-free environment to avoid contamination.

Why Choose ColDesi’s UV Printers for Second Surface Printing?

- Cutting-Edge Technology: Advanced printheads and software deliver unparalleled precision and quality.

- Comprehensive Support: ColDesi provides training, technical support, and resources to help you succeed.

- Custom Solutions: Printers like the 300H3F and 500H3F are tailored for second surface printing and other advanced techniques.

- Proven Durability: ColDesi’s printers excel in high-demand environments without compromising quality.

- Scalability: Whether you are a small business or a large enterprise, ColDesi’s solutions can grow with your needs.

Unlock the Potential of Second Surface Printing with ColDesi

Second surface printing can elevate your business offerings with premium, high-quality products. ColDesi’s UV printers enable businesses to tap into new revenue streams, meet increasing demand, and produce stunning results.

Second surface printing allows you to offer unparalleled durability and aesthetics. With ColDesi, mastering this innovative printing method is easier and more accessible than ever.

Empower your business to exceed customer expectations. Boost profitability by choosing ColDesi UV printers for your second surface printing needs. Transform your creative vision into durable, professional-grade results that set your business apart.