Many apparel decorating business owners find that their current customization technology runs into hurdles when examining their business scope.

Concerns such as: “How many orders can I handle at a time?” “How long will it take me to prep before printing?” and “What’s the quickest turnaround time where I can still make money?” are just a few examples.

Businesses need to examine the technologies available to help find the equipment that resolves concerns, answers these questions, and offers the most versatility to succeed.

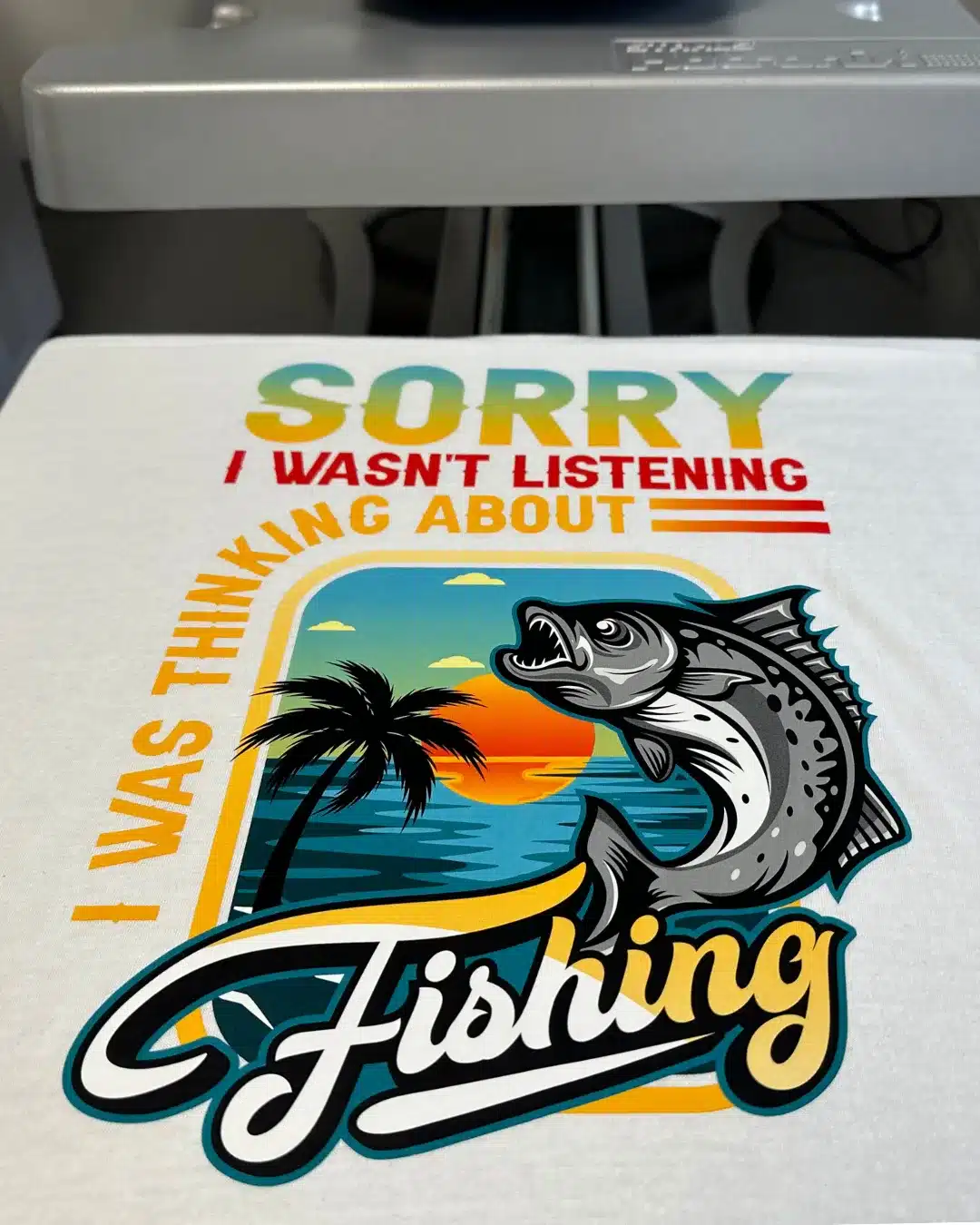

Luckily, a digital printing solution like a Direct-to-Film printer can be the answer. With DTF printing technology, it’s possible to print a vast number of intricate, vibrant images with less work.

Plus, the time spent making shirts decreases due to the ease of applying transfers. Finally, the speed of the printing process creates quicker turnarounds for bigger jobs. So, let’s discuss the secret to a versatile DTF printer business.

No Need to Convert Your Images

One difficulty with some technologies is the amount of preparation required before printing. Many other printing and decorating techniques, such as screen printing or embroidery, require more preparation to operate.

With screen printing, the process breaks down any image into individual colors. Each color needs a separate screen to be made and then, one at a time, each screen will place ink onto the surface of the item. Embroidery requires any image to be broken down into a file format that reads individual stitches and instructions, called digitizing.

This is then programmed into the embroidery machine. Preparations like these can add hours and potentially days to any print job.

What can DTF do instead?

Direct to Film can print high-definition, full-color images without any compromises. No need to worry about color layers and creating screens. Using the RIP software, it’s easy to lay out large-scale print jobs and get data about that print job on-demand. Then, all it takes is to start printing from that software.

There’s no need for any extra preparations. This makes printing any style of image approachable and easy. No need to work around the limitations of other printing technologies out there.

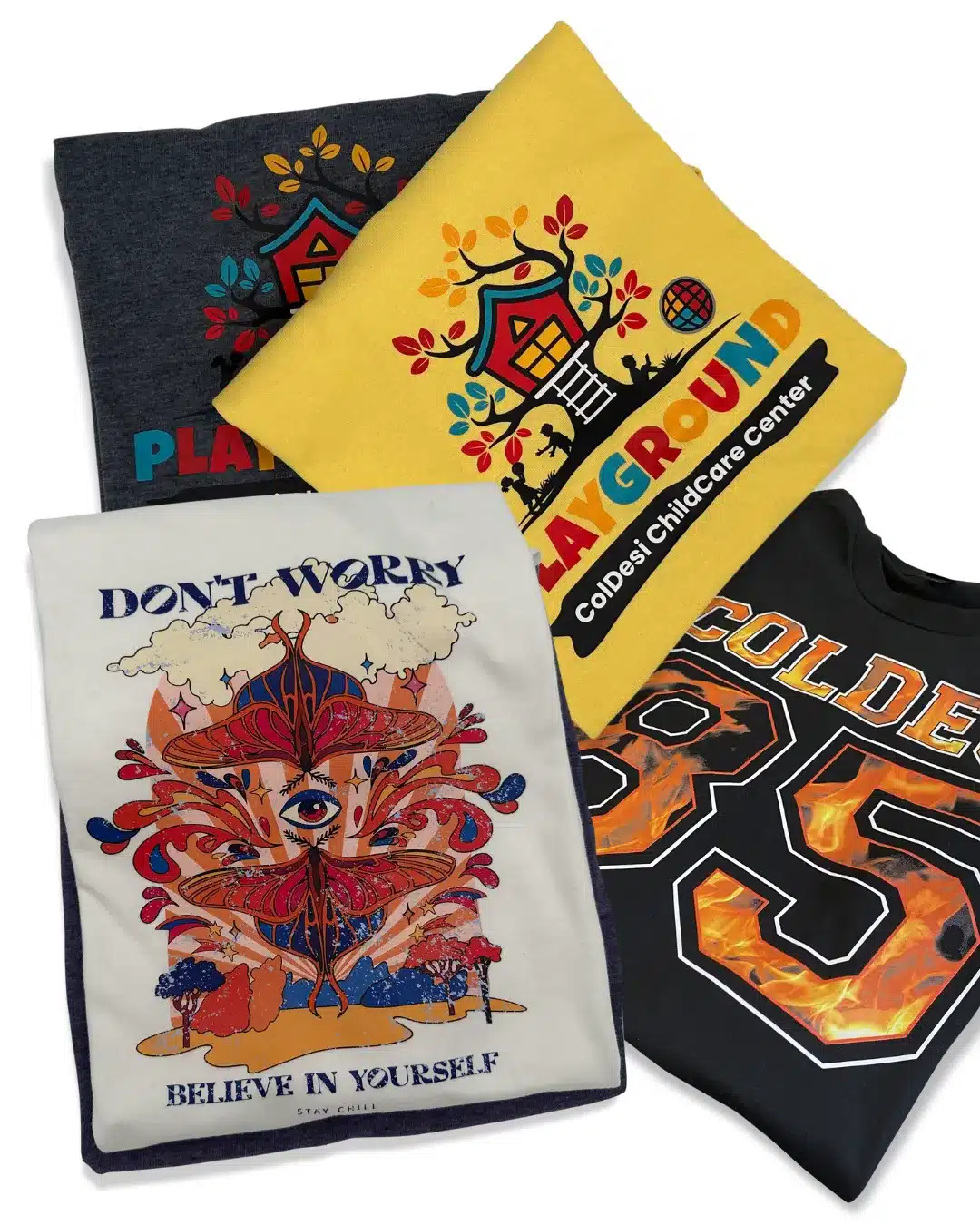

This opens the door to being able to offer more services to customers, handle intricate designs, and seize profitable growth opportunities. A versatile DTF printing business is always tackling new jobs.

Lowering the Time Spent per Shirt

Along with the amount of prep, the speed of creating shirts is up for debate. Common questions like, “How long will each technology take to make a single shirt?” “

Are there any limitations on what I can print?” and “How much physical labor does each technology take?” are important for businesses to know the answers to. Let’s consider another digital printing option, Direct to Garment (DTG).

The first time-consuming consideration of DTG is pre-treating the blank shirts. This process is necessary when printing on dark garments where you will be using white ink. Whether using an automatic machine or a manual process, pre-treatment will take time.

Combining that with a slower printing speed and the downtime from swapping shirts for each print this makes Direct to Garment printing only suitable for smaller print jobs.

Another example is screen printing. Manual screen-printing machines require physical labor to produce large print runs. As print runs continue, the labor may slow down, increasing that time.

Additionally, there is the time it takes to apply each layer of color and then the time it takes to finish drying in the curing oven. It all adds up.

How does DTF make a difference?

DTF can print hundreds of transfers at a time. These printers create transfers by printing directly on a special film, which is then heat pressed onto garments. One reason for the success of this process is that you do not need the blank garments to begin printing.

Speed is not limited to one shirt at a time. With film transfers, it’s no longer about how fast printing is per shirt; it’s about how well businesses can optimize pressing transfers. It also means that having a blank isn’t a requirement for printing.

DTF Printers can run while shirts are being pressed. Production doesn’t need to stop when the blank inventory runs out.

Handling Big Jobs in Record Turnaround Time

How can each technology handle large orders? For businesses, the best sign of success for any printing technology is the ability to tackle big print jobs.

You can do this by taking on orders like supplying school uniforms for each school year or providing sports fanwear for local teams during each sporting season. Handling large orders is key to profit.

Let’s continue with the Direct to Garment example. As covered before, Direct to Garment’s production speed is rather slow. It can produce excellent quality, but it can take several minutes to produce just a single shirt. Many businesses will use DTG printers for small print jobs or single shirts but will rarely take on print jobs greater than 100 shirts at a time.

Screen printing businesses can tackle larger print jobs, but the costs per production can limit small or moderate print jobs. The time and labor invested before printing even begins make it so that smaller orders may not be profitable at all. That is why screen-printing businesses often only take on large orders.

How does DTF perform?

DTF offers flexibility with easy application and independent printing capabilities. Competing with technologies like DTG, Direct to Film printing immediately outpaces the competition. The quality remains consistent across hundreds of transfers. DTF also removes the requirement of having a shirt to be able to print. This lets printing continue regardless of what blank garment inventory is available.

On the other hand, screen printing is notorious for its quality and scale of production, but the time investment means that only big print jobs are viable, as print jobs can take upwards of a day to prep. With minimal prep time, DTF can adapt to the needs of print jobs with tougher deadlines. Do you need a 500 t-shirt order in 36 hours? Is the inventory of blanks, supplies, and the design file available?

If yes, then a Direct to Film printer can get started right away and meet that window. If the client has their own heat press, then it’s even easier to print the transfers alone and sell those a la carte.

Flexibility is Key

So, what is the secret to a versatile DTF printer business? Flexibility. At every challenge, DTF provides the most opportunities with minimal compromise. When loading image files, there are no specific requirements or conversions needed. This makes Direct to Film a great option for printing high-resolution transfers, including complex designs with a large number of colors.

It takes little to no time to queue up for a large print job. With Direct-to-Film, the workflow is much more fluid. No need to stifle progress by moving and removing shirts. You can print transfers and heat press shirts simultaneously, avoiding downtime. The printer can handle the workload, so optimizing pressing transfers is key. This freedom provides room for businesses to tackle larger print jobs with confidence.

With a versatile DTF printer business, there is space and opportunity to expand, which is paramount for growth and success.