Selecting the Ideal Printing Technique: Direct to Film vs Screen Printing

Making the right choice in technology is a big decision for those entering the customization business. Knowing the differences is crucial to ensure the optimal decision based on your business’s size and scale. Here, we provide a comprehensive DTF vs Screen Printing Comparison with top tips from Don Copeland, a 20 year veteran of the industry.

Direct to Film printing (DTF) and screen printing stand out as popular options for customizing t-shirts. Each delivers high-quality results. In this article, we delve into a comparison of Direct to Film vs Screen Printing which will provide insights into both processes and their respective benefits.

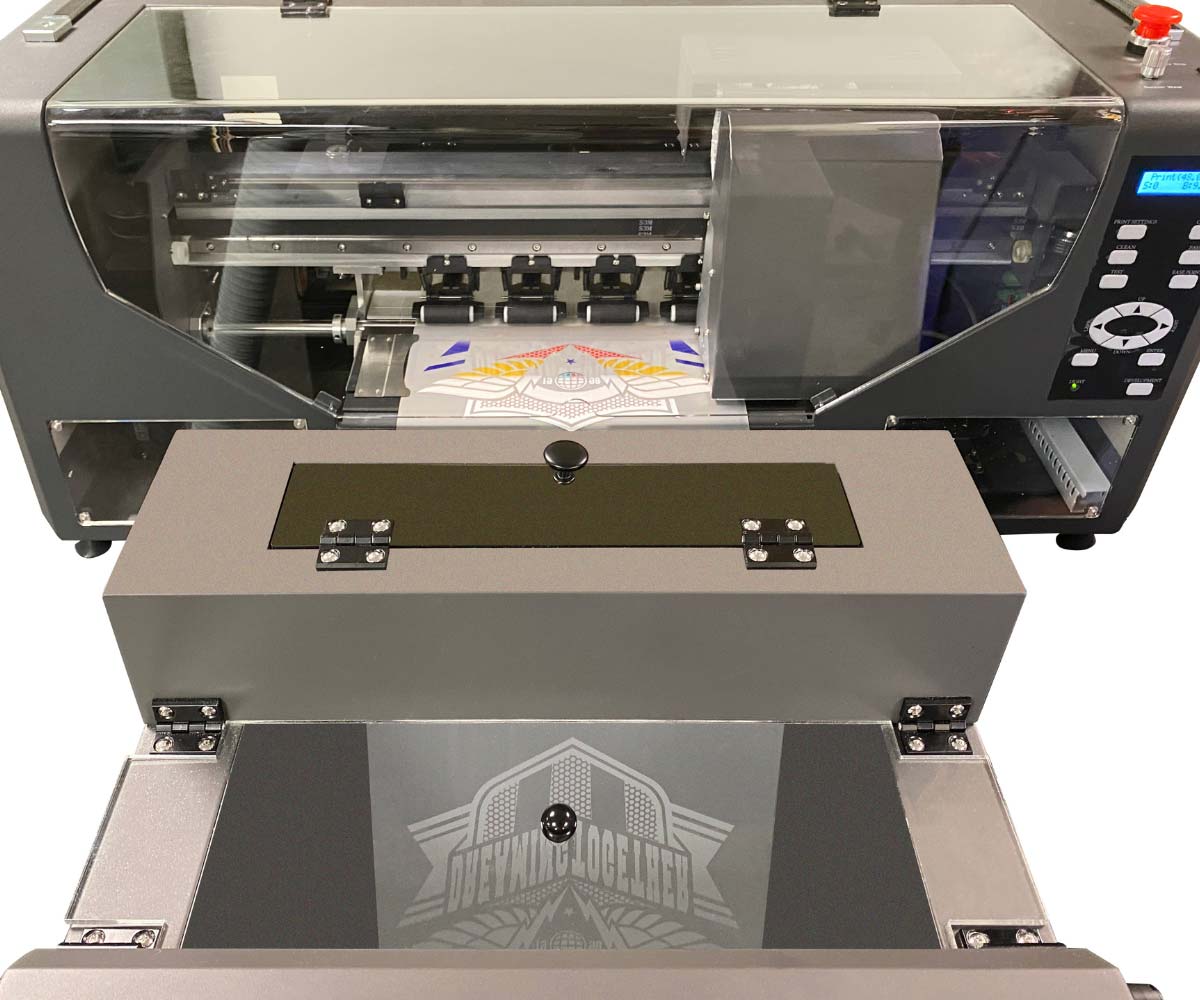

Direct to Film (DTF) Printing

The DTF process involves several key steps:

A DTF printer prints a design onto special PET film using CMYK (Cyan, Magenta, Yellow, Black) pigments, and white ink.

The printer first applies an ink layer, followed by a white ink layer over the entire image to enhance color vibrancy and provide a base for subsequent layers.

Next, the operator coats the wet ink with powder adhesive and removes any excess powder. They then heat the film, either in a curing oven or with a heat press, to prepare it for fabric transfer.

The operator applies the printed film to the garment using a heat press machine, adjusting specific temperature, time, and pressure settings according to the garment type.

After the heat press application, the operator peels off the film, revealing the vibrant print on the garment.

Finally, the operator heat presses the garment with the applied film, causing the adhesive to bind the colored pigments to the fabric and curing the entire transfer to make it permanent.

DTF printing offers several advantages:

- Capable of producing intricate and vibrant designs with a wide color spectrum.

- Works well on various fabric types, including dark fabrics.

- Generally faster than traditional screen printing for smaller runs.

- Allows for easy customization without extensive setup.

Screen Printing

Screen printing is a popular printing technique used in the customization industry. It involves creating a design by applying ink through a stencil or “screen” onto a substrate.

The process consists of several key steps:

- The desired design is first created, and then separated into different color layers. Each color requires a separate screen.

- Screens coated with a light-sensitive emulsion. The separated color layers transfer onto each screen using a photographic process.

- The emulsion-covered screen hardens when exposed to light. Except where the design transferred.

- You place the T-Shirt (substrate) onto the printing press. Align to ensure accurate color registration.

- In applying the ink, the operator coats the top of the screen and then uses a squeegee to push the ink through the screen onto the substrate. The operator repeats this process for each color layer.

- The operator passes the printed substrate through a dryer to cure the ink, making it permanent.

Screen-printing has several advantages:

- Versatile applied to various materials, including fabric, paper, metal, and more.

- Produces durable and long-lasting prints, especially on textiles.

- Cost-Effective for large quantities of the same design.

It also has some limitations:

- More intricate designs with more than one color can be challenging and time-consuming.

- The setup process can be labor-intensive, making it less suitable for small runs.

- Screen printing is not the best choice for detailed or photographic designs.

Screen Printing Machine vs A Direct to Film Printer

Adjusting to a changing market requires thorough research to understand the strengths and weaknesses of each option. DTF Printers produce hundreds of transfers, requiring space for machines and regular maintenance. Screen printing yields high-quality designs but involves the intricate process of designing screens and a lengthy application.

While screen printing provides impressive results, the time it takes to create transfers may not be sustainable compared to the flexibility and higher production speeds of DTF Printing. The choice between DTF and screen printing hinges on project-specific requirements.

DTF excels in vibrant, full-color designs on dark fabrics, making it cost-effective for both smaller and larger print runs. In contrast, screen printing is ideal for larger print volumes, especially with simpler designs, due to scalability and cost-effectiveness in high quantities. For projects featuring intricate, multi-color designs in various quantities, DTF proves superior.

To learn more about ColDesi’s line of DTF Printer visit our coldesi.com and Live Chat with a Pro below or call 877.793.3278.