At ColDesi, we are committed to empowering businesses with the knowledge and ability necessary to thrive in the custom printing industry.

Direct to Film (DTF) printing has transformed print customization, offering exceptional quality, versatility, and user-friendliness. Yet, to fully harness the potential of this technology, mastering these tips for DTF transfers will help. This includes understanding equipment, materials, best practices, and troubleshooting.

This resource page aims to refine your skills and optimize your DTF printing process, providing essential tips and tricks for consistently achieving outstanding results. Mastering DTF printing not only ensures vibrant, high-quality prints that impress customers, but it also enables confident navigation of the competitive printing landscape.

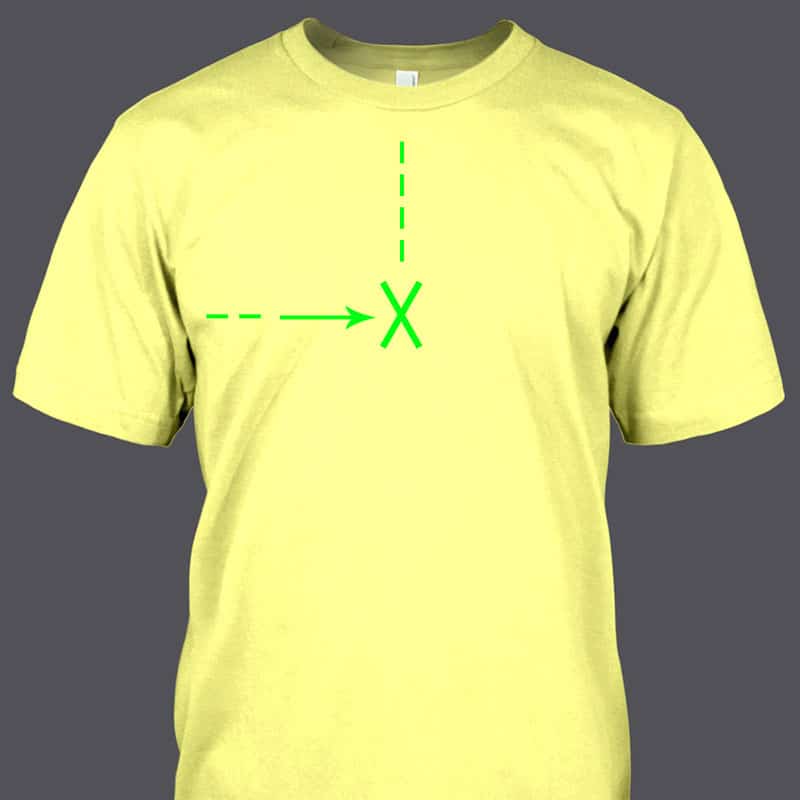

Heat Transfer Placement:

A Quick Guide for Perfectly Positioned Designs

For a better understanding of DTF transfer placement, check out: Heat Transfer Placement Quick Guide.

Ensure your designs stand out with precision placement techniques tailored to various garment types and sizes.

This article provides tips for DTF transfers and suggestions for achieving the best placement of heat transfers or cut vinyl transfers. Proper placement is crucial for a professional finish.

Enhancing Your DTF Artwork Creation and Production

For insights and strategies on DTF artwork creation and production, check out: 6 Artwork Tips for Direct to Film Transfers.

The article aims to help readers in achieving flawless prints and enhancing their custom decoration businesses.

It emphasizes the importance of pre-production and design phases, covering topics such as using negative space, adjusting color settings, simplifying designs, utilizing vector graphics, selecting proper software, and choosing the right DTF printer. Additionally, it suggests outsourcing artwork creation for those focusing more on production.

DTF Transfer Storage: Key Strategies for Longevity and Quality

For a better understanding and expert strategies on preserving the integrity and longevity of your prints, check out: Expert Advice on Storing DTF Transfers: Ensuring Longevity and Quality

Proper storage is crucial for preventing damage, preserving adhesion, keeping color vibrancy, preventing curling and damage, and ensuring usability. The article provides guidance on storing DTF transfers to ensure their longevity and quality, emphasizing the importance of proper storage practices.

It covers key considerations such as maintaining dry conditions, best room temperature, avoiding sunlight, using sealed containers, storing flat, avoiding stacking, and tracking freshness.

By implementing these crucial insights, businesses can enhance operational efficiency and optimize each stage of the DTF printing process, driving customer satisfaction and business growth. Join us as we delve into the essential skills, techniques, and best practices that elevate DTF printing success.

For more information on Direct to Film printing, contact us at 877.793.3278, and be sure to visit our website for articles, tutorials, product spotlights, and more!