Direct-to-film printing is all the buzz, but have you ever wondered how commercial, high-volume DTF Printers work?

In this step-by-step tutorial, we are using the all-new, compact DTF-12H2. It prints around 50 8”x10” transfers an hour! Here’s how it works:

1. The DT-12H2 printer has a dual print head design that lays down the colors in a blend of CMYK colors with the first printhead and then lays down a white underbase on top of the colors in perfect alignment so that you do not have any white peeking out.

2. The adhesive powder is then automatically added to the back of the transfers. It’s the unique powder adhesive coating that gives commercial DTF prints their signature soft touch. Instead of thick transfer films, or vinyl, the Direct to Film Process has only two ingredients. The ink and a thin coating of powdered adhesive.

3. The DTF printer uses PET transfer film, which is translucent, so you can see the design underneath the film when you later heat-press it onto the garment. The films used with the DTF-12H2 are both roll-fed and designed for a hot peel.

More Videos

Articles

ColDesi 24H5 vs. the Market: Setting the Standard for 5-Head DTF Printing

As custom apparel businesses grow, production demands increase. A 5-head DTF printer is the next logical step for print shops that need more speed and

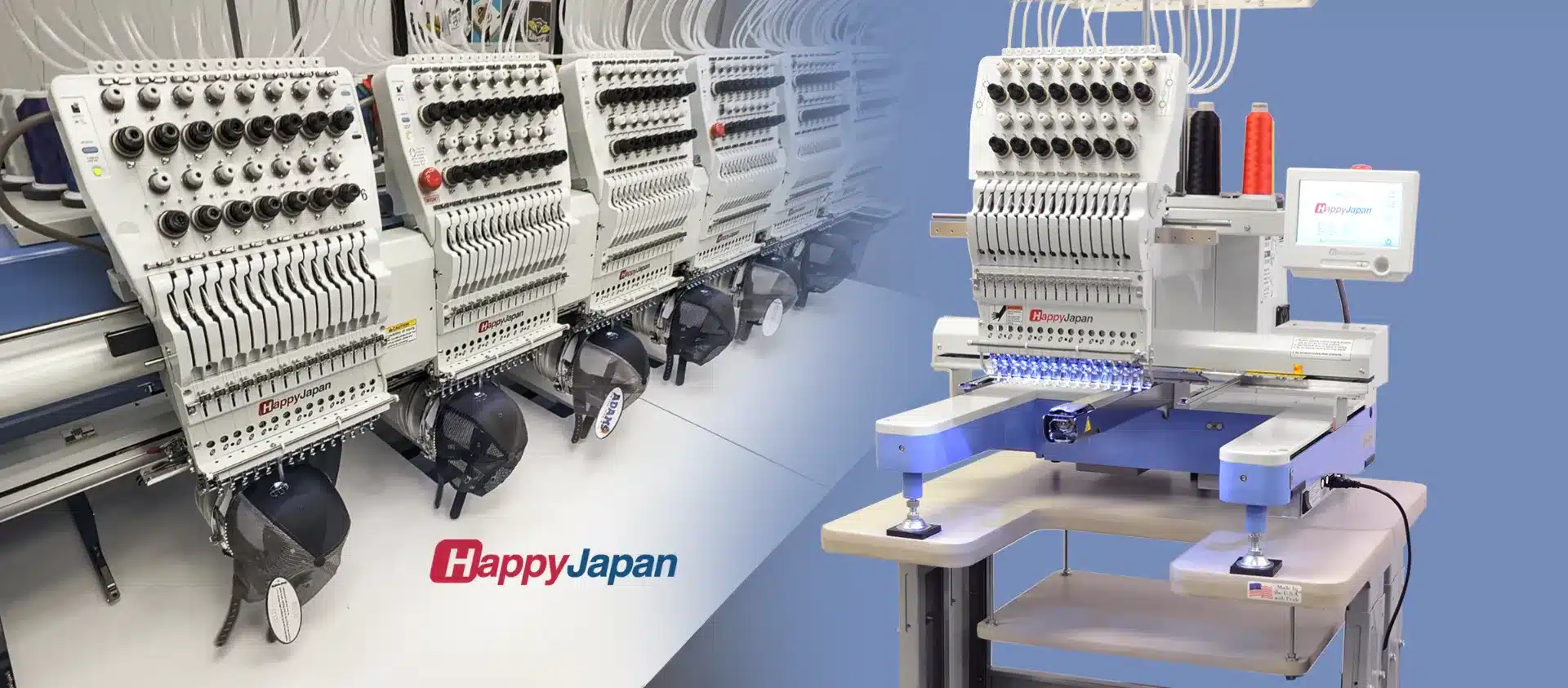

HappyJapan Single-Head Machines vs. Avancé Single-Head Machines

Choosing the Right Commercial Embroidery Solution When shopping for embroidery machines, businesses often weigh their options between proven industry leaders. The two top options are

Which HappyJapan Machine Is Right for You?

HappyJapan machines have earned a solid reputation in the commercial embroidery industry. They have been trusted by professionals around the world for over 90 years.