If you’re here, you’re doing what smart buyers do: you’re doing your homework before investing in a UV flatbed printer.

Let’s be honest, nobody just clicks “Buy Now” on something that pricey without making sure it will actually help their business grow.

And right now, you probably have a lot of questions running through your head, such as:

● “Which model delivers the best value?”

● “Will it print on the materials I use?”

● “How long before it pays for itself?”

And plenty more.

Those questions matter because the right printer can become a profit machine, while the wrong one can drain your time, money, and patience.

But how do you tell one machine from another? That’s exactly why we put this buyer’s guide together.

By the time you’re done here, you’ll know exactly which type of UV flatbed printer is worth your investment—and why.

Let’s jump in and make this decision a whole lot easier.

How UV Flatbed Printing Became the New Standard in Commercial Signage

Let’s take a quick tour through the evolution of UV printer development. And don’t worry, this won’t turn into a history lesson.

After all, UV flatbed printers didn’t just appear out of nowhere. They developed over time, little by little, the same way computers or smartphones did.

Each generation built on the last, adding new features, stronger components, and better results. That steady evolution is why they’re now widely favored by sign shops, decorators, and anyone who needs to print on materials thicker than a sheet of paper.

Makes you wonder… how did these machines even get their start? And how did they end up in nearly every decorator’s shop?

The story really begins in the early days of inkjet printing, long before UV printers were a thing. As far back as the 1950s and 1960s, researchers were tinkering with ways to place tiny, controlled droplets of ink onto a surface. It wasn’t glamorous work, but it laid the groundwork for everything that came later.

Fast-forward to the 1970s, and the idea of UV curing inks with ultraviolet (UV) light started taking shape. Early systems were used for extremely basic industrial work—barcodes, labels, direct mail, packaging. Flat, simple stuff.

The output was limited in color, slow to produce, and nowhere near what today’s printers can do.

But even in that early, rough stage, it planted an idea: What if you could combine digital printing with instant UV curing to print on almost anything—plastic, metal, glass, wood—without printing plates, screens, or transfer carriers?

That single question pushed the entire industry forward.

A decade or two later, in the mid-1990’s, a company called Data Mate developed and manufactured one of the first flatbed wide-format inkjet printers ever made, known as the “Rembrandt,” built around printheads from Sharp.

And they weren’t alone. Around this same time, several other companies were experimenting with (or releasing) these systems.

Then, as we rolled into the early 2000s, the race was on.

Manufacturers worked to overcome major limitations: slow speeds, poor adhesion, narrow material compatibility, and bulky equipment that only suited high-volume industrial users. Bit by bit, the industry solved those challenges.

Printheads became more precise. UV LED lamps replaced big, heat-heavy mercury bulbs. Inks got more flexible, more durable, and more dependable. And suddenly, UV printing wasn’t just for factories anymore—it became accessible to commercial shops, sign makers, promotional product decorators, and small businesses that needed crisp, durable prints without all the setup work.

Today, walk into almost any signage studio, a custom décor shop, or a promotional printing workspace, and the odds are high that the signs, panels, and printed pieces you see were produced on UV flatbed equipment.

It’s become the industry standard because it’s fast, versatile, clean, and profitable—exactly what modern shops need.

And that’s exactly where ColDesi UV Printers enter the story.

Do you need a refresher on what UV printing is exactly, and how it works? We’ve put together a quick guide for that.

The Best Flatbed UV Printers Worth Your Investment

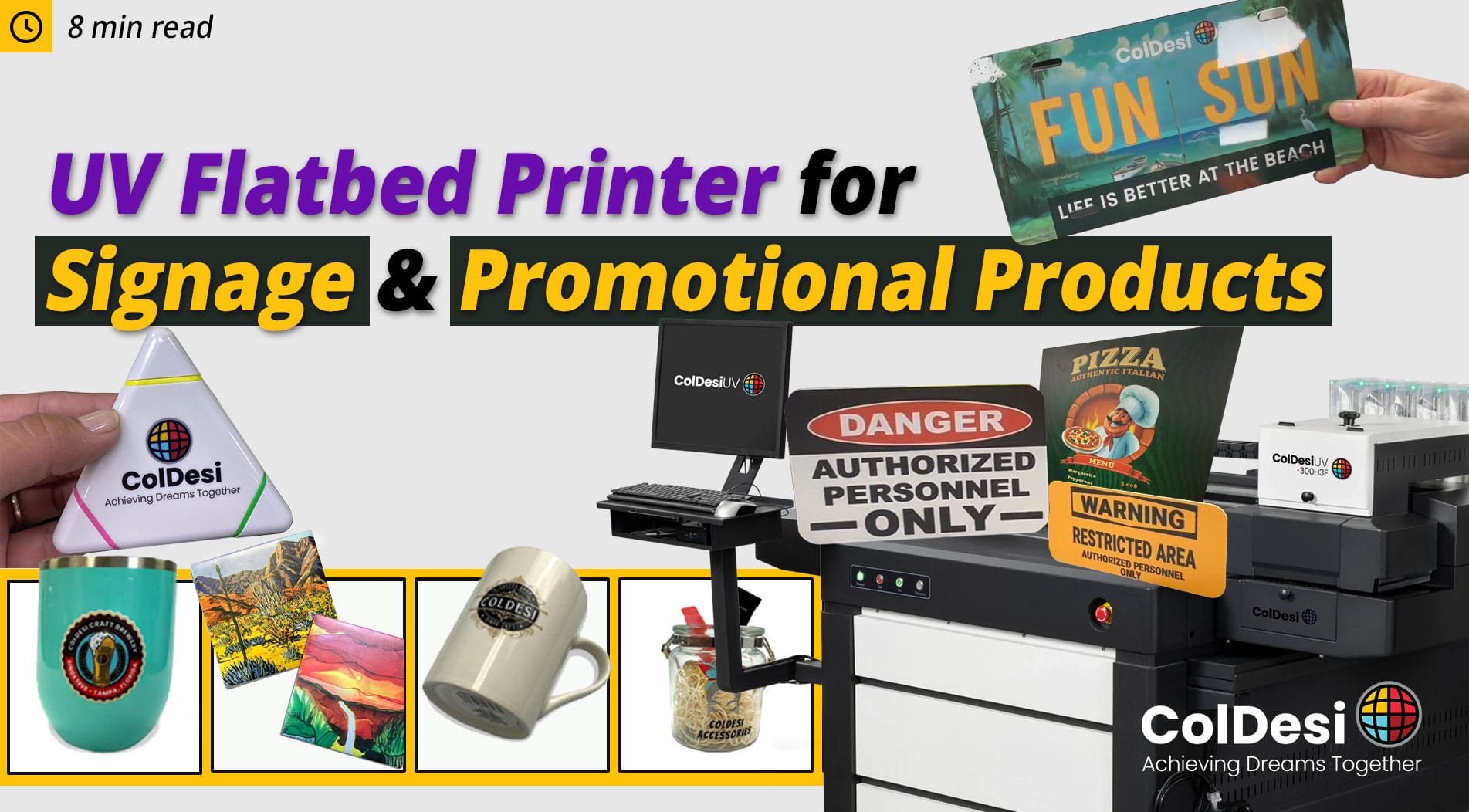

If the headline or thumbnail brought you here, you’re after one thing, the right UV printer for your business.

So, let’s not drag this out and get right to the point.

Up next, we’ve got two of ColDesi’s newly released flatbed UV printers lined up for you.

They may be recent releases, but they’ve already been run through real production environments, earned solid customer feedback, and proven themselves worthy of their place.

On top of that, we’re also including a hybrid UV/DTF model that combines the strengths of ultraviolet and direct-to-film printing. Put together, these options give you flexibility in choosing the best flatbed UV printer for you and your business.

With that, let’s take a closer look at each flatbed UV printer in our range and go over their unique feature set.

ColDesi UV 300H3F – A high-performance UV flatbed printer built for direct-to-object printing on a wide variety of rigid and cylindrical materials.

It offers a generous 36″ × 24″ inch maximum print area, giving you plenty of workspace for both small products and larger custom pieces.

This versatile machine features an integrated rotary system for cylindrical items and an automatic height measurement system, allowing you to print on objects up to 9+ inches tall. It’s ideal for applications involving irregular shapes and three-dimensional surfaces.

The ink level detection system is another handy addition. The cartridges have lights that let you know exactly where your ink levels are, so you don’t suddenly run dry in the middle of a job.

There’s also a print head collision prevention system, which uses anti-crash sensors to stop the moving print head if something’s in the way. It pauses the machine and brings it back to the starting point so you can make adjustments without risking damage.

And believe it or not, these highlights barely touch on everything it can do.

ColDesi UV 500H3F – A high-performance commercial flatbed printer with an impressive 63×47 inch print area, offering roughly 1.85× more printable area than its “little” brother, the UV 300H3F.

It features a multi-zone vacuum table and a six-channel UV-LED ink system (CMYK + White + Varnish).

The 500H3F can print on objects up to 5.9 inches tall.

This height is lower than that of 300H3F, but it is intentionally designed for users who prioritize maximum bed size and production efficiency over additional vertical height.

The printer also includes ink-level detection and printhead collision-prevention systems to make operation effortless and safe.

At roughly 2,170 lb, it’s nearly twice the weight of its little brother.

This added mass is a proof that all that extra capability had to go somewhere.

ColDesi 24H3R UV DTF Printer – As an added bonus, we also want to highlight one of our hybrid printers: the ColDesi 24H3R UV/DTF printer. While it’s not exactly a 1:1 DTF printer, it carries that technology in its DNA. This multi-purpose printer combines the strengths of both UV (ultraviolet) and DTF (direct-to-film) printing.

Transfers produced with this system can be applied to a wide variety of hard surfaces, including flat or uneven areas, cylindrical or conical shapes, arcs, concave surfaces, and other irregular forms.

The printer is a roll-fed UV DTF system designed for creating durable, full-color decals and adhesive transfers on materials such as plastic, glass, metal, wood, and ceramic. It is built for high-speed production, allowing businesses to efficiently customize items like tumblers, awards, and equipment. The process is handled all in one go, eliminating the need for separate steps such as weeding or lamination.

To round things out, it’s worth mentioning a few practical details as well. The printer offers a generous 600mm print width, giving you plenty of room to work with. The machine itself has some weight to it at about 397 lbs, which helps keep everything stable during longer prints. And in terms of output, it runs at about 43 to 55 square feet per hour.

You’ve done the reading, looked at the options, and worked your way through a forest of specs and features. That’s the homework you were supposed to do.

But at this point, it’s less about the machines and more about what your business actually needs. Think about the jobs you want to take on, the customers you want to serve, and the kind of production environment you want to run.

Once you’re clear on that, the right printer becomes much easier to choose. The specs help, but your workflow ultimately guides the choice.

So what else needs to be said?

Just this: Whichever printer you pick, you’ll learn it, you’ll work with it, you’ll make it pay off.

From here, we’ll look at the materials these machines are designed to work with.

What Can You Print on With Flatbed UV Printers

Next, it helps to understand the range of materials these machines can handle and, in turn, what you can actually create with them.

What are the practical applications? What do customers ask for? And where’s the real money to be made?

In this section we’ll clear things up for you. We’ll walk you through the most popular products and ways UV printers are used in signage.

Materials Compatible with Flatbed UV Printers

- Acrylic

- Metal

- Glass

- Wood

- Leather

- Stone and slate

- Rigid Textiles

- Rubber (hard, non-flexing)

- PVC

- Ceramic

- Polycarbonate

- Promotional substrates

CAUTION: While these materials are generally compatible with flatbed UV printers, each one has its own considerations, including surface preparation, adhesion risks, curing behavior, and heat sensitivity. Some materials may also have coatings, sealants, or treatments that are not obvious at first glance. To avoid wasted material, reprints, or unexpected results, it is best to test a small area first and confirm that the adhesion and finish meet your expectations.

In-Demand Product Categories in Signage & Industrial Applications

- Warning & Safety Signs

- Directional Signs

- Outdoor Signage

- Event Signage

- Advertising Boards

- Window Graphics

- Nameplates

- Guidelines

- Labels

- Billboards

- Banners

- Posters

- Merchandise

- Plaques

- Panels

- Packaging

- Awards

We looked at the types of materials you can work with, along with the products you can make with them.

And when you think about all the material types, all the product types, and the variations within each, the possibilities do start to feel endless.

You might choose one material for a product, then a different material for that same product, and so on. Or you might switch to an entirely different product altogether.

In the end, this gives you the ability to create practically anything that’s possible within realistic bounds.

Did this have you momentarily imagining what you could create and what might be possible with all this?

Good.

Because honestly, you could take any one of those items on the list and build an entire business around a single winning product.

And the truth is, that’s not even the full list of what you can create in signage—this was just the beginning!

But with that freedom comes something just as important: the need for dependable performance.

You need materials and production standards you can rely on, from how cleanly your graphics print to how strongly they bond and how well they hold up over time.

So, let’s talk about that next.

Performance You Can Count On

With the basics behind us, the next thing to focus on is the printer’s performance. And no, we’re not talking about metrics, specs or charts here.

If you’ve followed along this far, you already know that the output quality from the ColDesi UV printers is exactly what you’d expect from modern equipment: fast print speeds, a solid set of features, sharp, readable text and graphics, smooth gradients, and a rich color range.

Which brings us to the real question: Why does any of this matter? Why not just buy the cheapest printer you can find and call it a day?

Because your business runs on the experience you create for your customers. They’re the reason you’re here. And if the final product doesn’t live up to their expectations, well… you won’t be producing much for long.

That’s why, before you choose a UV printer, it’s worth zeroing in on the things that actually matter: print quality, adhesion strength, and long-term durability. These are the areas where lower-tier printers often fall short and where ColDesi machines excel.

Print Quality – Our flatbed UV printers set a new standard in color reproduction. The resulting prints outperform traditional and outdated methods such as screen printing, vinyl, and sublimation, and also stand above many competing UV solutions on the market.

Every print that comes out of the UV printer looks absolutely stunning! The colors are vibrant and the details are sharp. Both text and images appear crisp and easy to read, thanks to the print’s utra-high resolution.

These prints are not only color-accurate and vibrant but also provide deep contrast and rich blacks for stunning visual impact.

Beyond their visual appeal, the texture of the prints is smooth and pleasant to the touch.

All of these qualities combined make them suitable for both indoor and outdoor applications.

You won’t have to second-guess whether your products hit the mark. Your signs, displays, or promotional products will speak for themselves.

Adhesion Strength & Durability – Next on the list is adhesion strength, which is an area where entry-level UV printers typically fall short.

To illustrate this point, think about it: have you ever had a customer come back complaining that their print scratched too easily, or that the colors started fading or peeling after just a few days in the sun?

No one wants to hear those complaints, yet they’re all too common with budget UV printers or traditional printing methods.

Our flatbed UV printers significantly reduce those customer complaints and the need for reprints.

Prints produced with our UV technology resist fading, scratching, and weathering, and can withstand a wide range of environmental conditions—including moisture, extreme temperatures, direct sunlight, and exposure to cleaning agents.

This leads to happier clients, more referrals, and greater satisfaction in your work.

Plus, these prints can maintain their quality for over two years without any noticeable fading or degradation.