What is UV Direct to Substrate Printing?

UV direct to substrate printing is a significant advancement in digital printing technology. It leverages ultraviolet (UV) light to cure, or dry ink, instantly as it is applied.

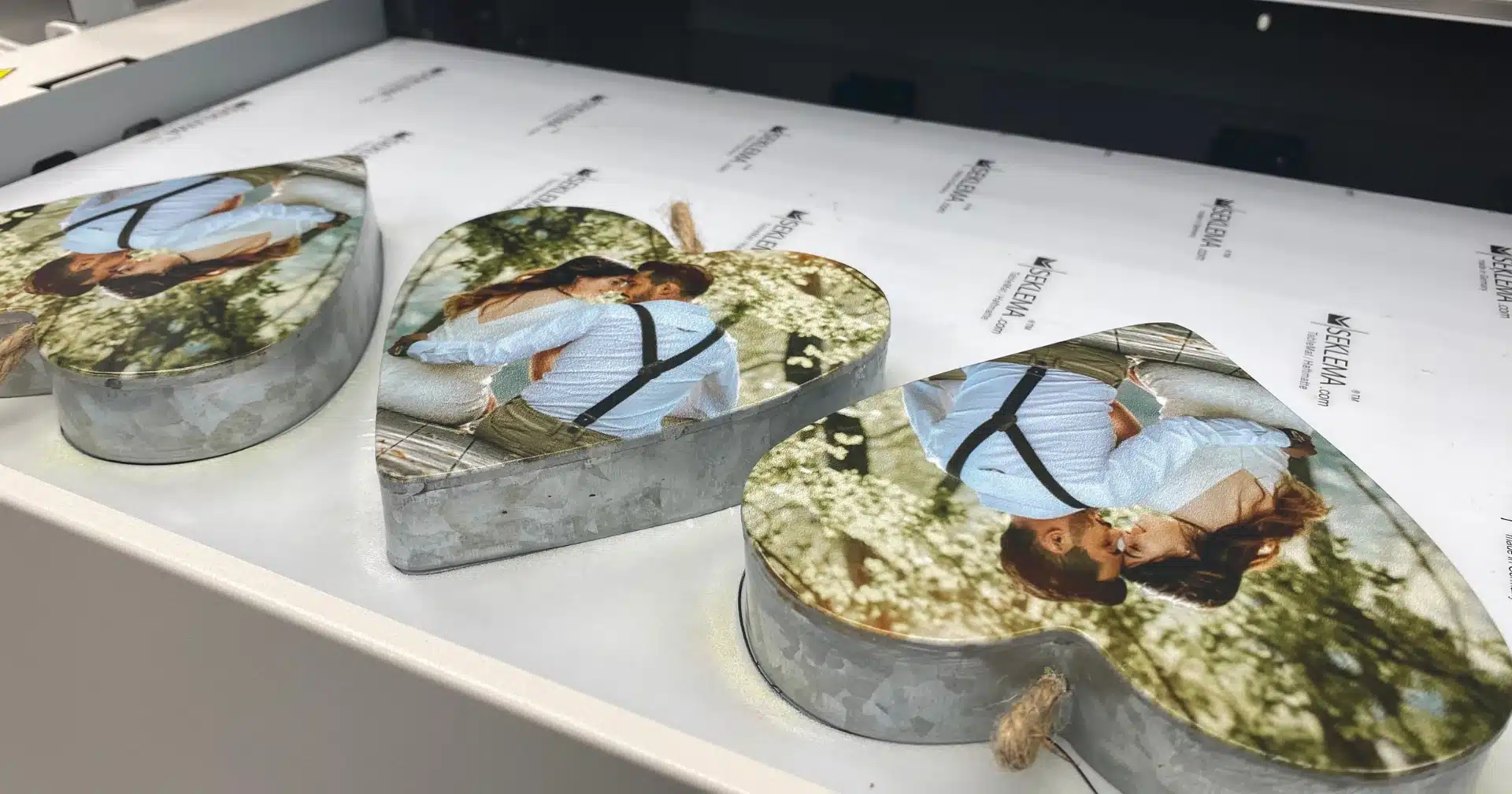

This method enables printing on a diverse array of surfaces, including but not limited to glass, metal, wood, and even leather, making it ideal for producing custom signage, promotional products, and personalized items.

UV Printing Technology Advantages

The process uses a technique like traditional inkjet printing, yet UV printing utilizes specialized UV-curable inks. As the ink is deposited onto the substrate, it is immediately cured by powerful UV lights.

These lights, positioned near the print nozzle, solidify the ink, creating detailed, multilayered prints that can include vibrant colors, white ink, and varnishes. This process enhances durability and textural variation.

How UV Printing Works:

-

Inkjet Printing Technology: UV printing employs specialized UV-curable inks instead of standard inks.

-

UV Curing: UV lights immediately cure the ink as it is applied to the substrate, transforming it from liquid to solid form.

-

Multi-Layer Printing: The printer applies many layers of ink, including white ink and varnishes, to create detailed, vibrant, and textured prints.

Common Applications of UV Direct to Substrate Printing

UV printing is applied in various sectors. It is perfect for both indoor and outdoor signage due to its durability. In the retail sector, it is used for packaging everything from cosmetics to food, where visual appeal and robustness are crucial.

It is also used in decorating items like phone cases and unique gifts. UV printing serves industrial purposes in the automotive and electronics industries, producing durable labeling.

Advantages of UV Direct to Substrate Printing

A key benefit of is its ability to produce vivid, sharp images, thanks to the immediate curing of the ink, which prevents spreading and absorption into the substrate. This process enhances color saturation and detail while also improving productivity, as the printers can manage large volumes in less time.

Printing on the material also reduces the need for more protective layers, thereby cutting costs and simplifying the production process.

UV Direct to Substrate Printing: Advantages

-

Quick Drying Time: The rapid curing minimizes interaction with the substrate, allowing for use on a broader range of materials, including heat-sensitive ones.

-

Enhanced Image Quality: The ink dries instantly preventing dot spread and absorption into the substrate, which results in sharper and more vibrant visuals.

-

Increased Productivity: The fast-curing process enables high-volume production in shorter times.

-

Cost Efficiency: Printing on the substrates reduces the need for extra materials, such as laminates, lowering production costs.

-

Versatility in Finish Options: Prints can be produced with various finishes, from matte to high gloss, depending on the desired aesthetic.

-

Lower Energy Consumption: UV-LED printers use less energy and many feature adjustable LED lights that enhance energy savings.

-

Environmental Benefits: UV printing produces fewer volatile organic compounds (VOCs), odors, and heat. This contributes to a more environmentally friendly production process.

-

Additive Process: UV 3D printing technologies allow for the addition of textured elements, such as ADA-compliant raised characters and braille, using a single device.

Durability of UV Printing

Requirements for UV Direct to Substrate Printing

Investing in a high-quality UV printer and ink is essential for achieving optimal results. A variety of substrates can be used and compatibility with design software is crucial to ensure smooth operation and high-quality outputs.

-

UV Printer: Investment in a high-quality UV printer is crucial for achieving crisp, vibrant, and durable prints.

-

UV-LED Ink: Investment in a high-quality UV printer is crucial for achieving crisp, vibrant, and durable prints.

-

Substrates: UV printing accommodates a wide array of materials, including acrylic, aluminum, and PVC.

-

Design Software: Compatibility with UV printers is necessary to ensure efficient print design and production.

The versatility, durability, and quality of UV direct to substrate printing make it a transformative choice in the printing industry. It is suitable for a myriad of applications and likely to continue evolving with UV printing technology advantages.

ColDesi is a premier provider of UV printers, inks, and supplies. Backed by our world-renowned training and support, our team is dedicated to assisting you in your journey to produce high-quality UV prints.

The versatility of our lineup of UV Printers is unmatched. Live chat below with one of our pros or call 877.793.3278 today.