Over the past decade, the printing industry has seen significant advancements in technology, prompting businesses to reassess their current customization methods.

Outdated customization technology does not always meet growing consumer demands or the changing economy. Commercial printing and textile decorators planning expansion must adapt to evolving markets while ensuring profitability and staying competitive.

Textile decorators generating around $1 million in annual sales may have reached an operational threshold. This means scaling further would require strategic changes to manage changing demand and maintain profitability.

Screen printing is inherently less scalable compared to modern digital printing technologies, which efficiently accommodate varying order sizes with minimal incremental costs or resources. Scaling screen-printing operations requires significant investment in new machinery, larger facilities, and an expanded workforce to manage the complex processes.

Traditional screen printing, while reliable, is increasingly showing its limitations in the face of the on-demand economy. Direct-to-Film (DTF) is a compelling alternative that addresses these limitations and offers a pathway to expanded capabilities and revenue growth.

Challenges Inherent in Screen Printing

- Time-Intensive Setup: Screen printing requires creating physical screens for each design. These screens demand considerable time and skilled labor. This makes it less efficient, particularly for smaller or custom orders.

- High Overhead for Small Runs: The economics of screen printing favor bulk production. Smaller runs often result in disproportionately excessive costs, making them less profitable. As the on-demand market grows, screen printers cannot compete with DTF’s pricing for small-run orders.

- Limited Design Adaptability: The process is less suited for intricate, multi-color designs. It is typically restricted to flat surfaces, limiting its versatility.

- Environmental Impact: The waste associated with screens and excess ink contributes to higher costs and environmental concerns.

The Strategic Advantages of DTF Printing

Versatility Across Substrates

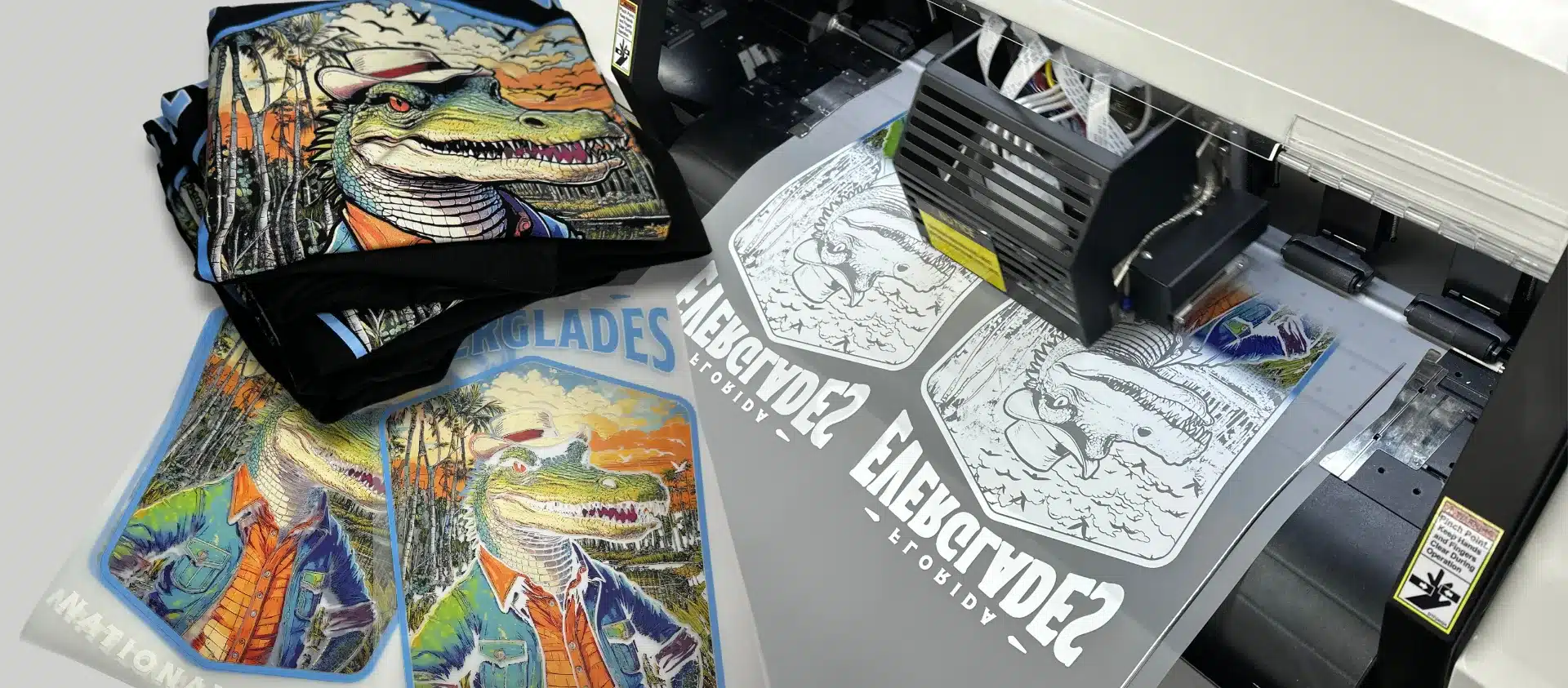

DTF printing is compatible with a wide array of materials, including natural fibers, synthetic fabrics, and blends. This broad compatibility allows textile decorators to serve diverse markets, from fashion and promotional items to custom home decor and beyond.

Reduced Production Costs

By eliminating screens and streamlining production processes, DTF significantly lowers setup costs. This reduction is particularly helpful for custom and small-batch orders, where traditional methods struggle to remain profitable.

Superior Customization Options

DTF printers produce intricate designs with vivid colors and sharp details, ensuring consistent quality across projects.

Accelerated Turnaround

The simplified workflow allows businesses to deliver orders quickly, meeting the increasingly short lead times demanded by modern customers.

Sustainability Improvements

DTF minimizes waste by using less ink and eliminating the need for disposable screens. This makes it an excellent choice for textile decorators aiming to adopt eco-friendly practices and reduce their environmental footprint.

Article: “Should Your Business Bring DTF Printing In-House?” explores the benefits of adopting Direct-to-Film technology. It highlights how DTF printing enhances efficiency, improves print quality, reduces costs, and expands design capabilities, making it ideal for businesses seeking to stay competitive and diversify their customization offerings.

Economic Benefits for Established Businesses

- Lower Operational Costs: Automation and simplified workflows reduce the reliance on skilled labor, translating to cost savings.

- Increased Profitability: DTF enables businesses to efficiently produce small runs and customized orders, unlocking new revenue streams.

- Market Expansion: DTF prints work on various materials and offer unique designs, allowing businesses to attract new customers and capture niche markets.

- Rapid Return on Investment: The cost efficiencies and revenue opportunities provided by DTF speed up the return on new equipment investments.

Article: “Exploring the Differences: Screen-Printing Machine vs. Direct-to-Film Printer” compares traditional screen printing with modern DTF printing. It highlights how DTF offers faster setup, full-color flexibility, and cost-effective production for small to medium orders, making it ideal for dynamic customization needs. Perfect for textile decorators evaluating printing methods to optimize efficiency and quality.

Comparing DTF and Screen Printing

Simplified Prepress Workflow

Unlike screen printing, DTF printing eliminates the need for prepress preparation. Digital files are directly transferred to the film, streamlining the production process and reducing setup time.

Durable, High-Quality Output

DTF prints are known for their longevity, with resistance to cracking, peeling, and fading. These attributes ensure customer satisfaction and enhance brand reputation.

Steps to Transition from Screen Printing to DTF

Switching to DTF printing is a manageable process with proper planning and execution. Follow these steps to ensure a successful transition:

1. Check Operational Needs

Assess the limitations of your current screen-printing setup. Identify areas where DTF technology can provide immediate benefits.

2. Choose the Right Equipment

Invest in high-quality DTF printers from reputable suppliers like ColDesi. Consider factors such as production capacity, compatibility with existing workflows, and scalability.

3. Train Your Team

Comprehensive training is essential for ensuring a seamless transition. Leverage resources and support provided by equipment manufacturers to upskill your staff.

4. Integrate Gradually

Introduce DTF printing alongside existing operations to minimize disruptions. Evaluate the new technology with select projects before fully committing to it.

5. Promote Your New Capabilities

Market your enhanced service offerings to existing and prospective clients. Highlight the benefits of faster turnaround times and superior quality to attract new business.

Article: “Expanding Your Screen-Printing Business with DTF Technology” highlights how DTF printing complements screen printing. It enables full-color prints on various fabrics, reduces costs, and expands customization options, helping businesses diversify and stay competitive in the growing on-demand market.

The Imperative to Modernize

Businesses that embrace innovation will be better equipped to thrive in this competitive environment. Textile decorators transitioning from screen printing to DTF can meet evolving customer demands by improving operational efficiency and unlocking new growth opportunities.

Modernize your printing operations by exploring the advantages of DTF technology. ColDesi’s cutting-edge equipment, comprehensive training, and dedicated support provide textile decorators with the tools needed to succeed in today’s market.

Visit our website, chat with a Pro, or call 877-793-3278. Learn how DTF printing can revolutionize your business and drive long-term success.