For any developing t-shirt business, there is the technology to fit every idea. With the number of printing options available, it is important to understand the differences in equipment. Here we give you a DTG vs DTF business comparison to help you decide.

Some popular options for making t-shirts include Direct to Film (DTF) and Direct to Garment (DTG) printers. With these two being so popular, this invites a common question: What is the difference between DTG and DTF?

Direct to Garment | Tackling Complex Designs with Ease

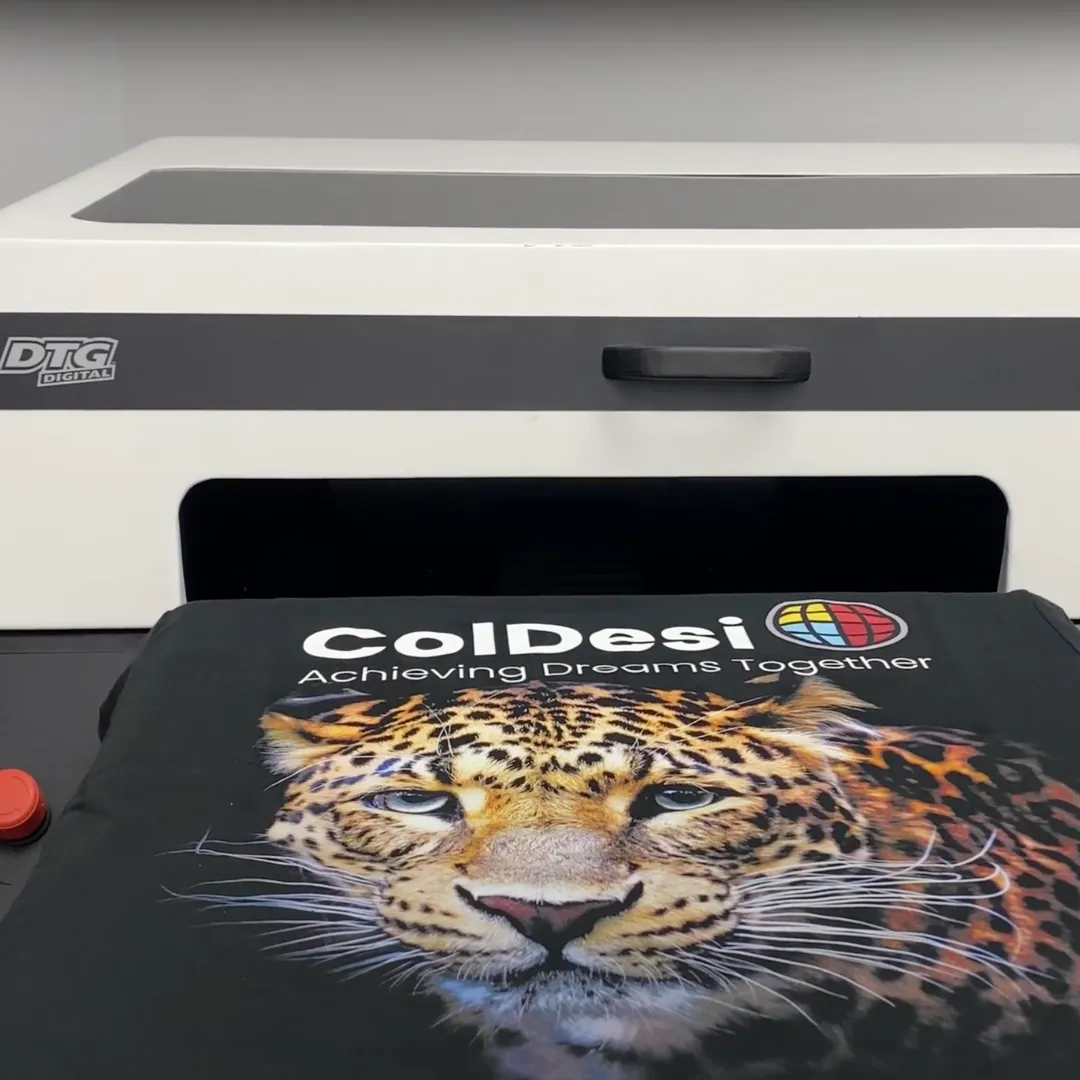

As the name implies, DTG stands for Direct-to-Garment printing. This means that this printer prints a design directly onto the textile. This process avoids dealing with any transfer paper or films, unlike other methods.

With DTG, there are two main factors when it comes to printing designs. The first thing to note is that DTG printing works best on 100% cotton shirts and materials.

The next item to consider is how to handle pre-treatment. Pre-treatment is necessary for the inks to adhere to the shirt. There are several available options for handling pre-treatment with a DTG business. Some vendors sell pre-treated garments and textiles.

There are also pre-treatment machines that allow businesses to handle this step themselves.

One major difference between DTG and DTF is the scale of printing jobs. DTG is best suited for smaller print jobs. Because this process prints on one shirt at a time, the total customization time will add up.

This is due to all the time it takes to customize a shirt, load the artwork, print the design, and cure the inks. In return for the time investment, DTG provides premier color vibrancy and detail. Because DTG works with one t-shirt at a time, businesses thrive with print runs under 100 garments.

This means success in retail storefronts, custom orders, or small online shops.

When the printing finishes, maintenance highlights another difference between DTG and DTF. Daily DTG printer maintenance includes cleaning all the heads as well as shaking the ink. There are weekly and monthly steps as well, but the level of daily maintenance is minimal with DTG.

This means that the necessary steps to start a day of printing will take less time. DTG printing provides quality prints with vivid detail and color vibrancy. Important to know when doing your DTG vs DTF business comparison.

Direct to Film | High Performance for High Expectations:

Where DTG succeeds in smaller print jobs, DTF excels in creating a multitude of transfers at a time. Because DTF prints on film, this technology is not limited to what can fit on one singular t-shirt. High production DTF printers will handle every step of the transfer process.

This process includes printing, powder application, and then curing the transfer. Because of the powder included in the DTF process, there is no pre-treatment needed.

Focusing on production speed, DTF runs far ahead of DTG for anything above a small-scale job. Because many DTF printers print roll to roll, there is plenty of space for several orders at the same time.

Along with plenty of print space, many DTF printers also carry superb print speeds. Without the need to worry about swapping out shirts between prints, DTF saves plenty of time over DTG. These factors mean that DTF printers work best for high-production environments. An average workday for any DTF business can include printing hundreds of transfers a day.

With transfer printing covered, the focus then turns to putting the transfers onto shirts. DTF printers fit best with businesses willing to push them to the limit.

Now, before and after a long day of printing, maintenance is pivotal to keeping a DTF printer healthy. Cycling the ink to prevent clogging and reclaiming DTF powder is just a few of the maintenance steps. DTF maintenance is even more important than DTG.

This is because downtime has a much bigger impact. Printing more transfers means that downtime creates bigger losses in time and money. If the goal of the business is to take on massive transfer orders, DTF takes the lead.

DTG vs DTF Business Comparison | Making the Right Decision

DTG and DTF printers can help evolve businesses with the right plan, but which is right for your business? Highlighting scenarios of success will help find the best printer for the job.

If your business:

- Prints custom t-shirts to order.

- Provides the highest quality detail on designs.

- Wants vibrant prints with long lifespans on cotton t-shirts.

- Handles print jobs in sizes less than 100 garments.

Then a DTG Printer will be best for your business.

If your business:

- Produces transfers.

- Wants flexibility in print job sizes.

- Wants vibrant prints with great stretchability.

- Wants transfers that work with almost every type of fabric.

- Has print jobs of sizes greater than 100 garments.

Then a DTF Printer will be best for your business.

What’s Next for Success?

Understanding the difference between DTG and DTF is important for growing a business, but learning more about both technologies invites more questions.

Recognizing the right machine for your business helps turn dreams into reality. When it comes to growing a business, ColDesi has decades of experience and provides support and training to give you the tools to stand out and succeed.

To learn more about ColDesi’s line of DTG and DTF printers visit our coldesi.com and Live Chat with a Pro below or call 877.793.3278.