The Importance of a DTF Heat Press for Durable and Professional Transfers

A DTF Heat Press is one of the most important tools in the direct-to-film printing process. The printer, inks, and film often get the most attention, but the heat press determines whether the transfer bonds and lasts. It applies time, temperature, and pressure to cure the adhesive powder. This process fuses the transfer to the garment. Without the right press, even the best printer cannot deliver consistent results.

Choosing the correct DTF Heat Press is essential. It ensures durability, wash resistance, and customer satisfaction. A reliable press provides steady heat and pressure. This prevents peeling, uneven adhesion, and color loss.

The Function of a DTF Heat Press in Direct-to-Film Printing

- Long-term wash resistance

- Color vibrancy retention

- Overall product lifespan

- Transfers peel or lift after washing

- Incomplete curing reduces vibrancy

- Uneven adhesion creates weak spots in the design

Core Capabilities to Evaluate in a DTF Heat Press

- Even Heat Distribution – Uniform platen heat prevents under-curing and ensures proper adhesion.

- Accurate Temperature Control – Digital controls with minimal fluctuation ensure repeatable, high-quality results.

- Consistent Pressure Application – Adjustable, evenly applied pressure activates the adhesive layer across the full design.

- Durability for Production – Heavy-duty construction supports continuous use in commercial environments.

- Platen Versatility – Interchangeable or specialty platens allow transfers on different items and surfaces.

- Temperature Range and Stability – Wide, stable ranges between 0–250°C (32–482°F) ensure reliable curing.

- Digital Controls – Provide precise adjustments for time, temperature, and pressure.

- Safety Features – Auto-shutoff, overheat protection, and sturdy builds enhance operator safety.

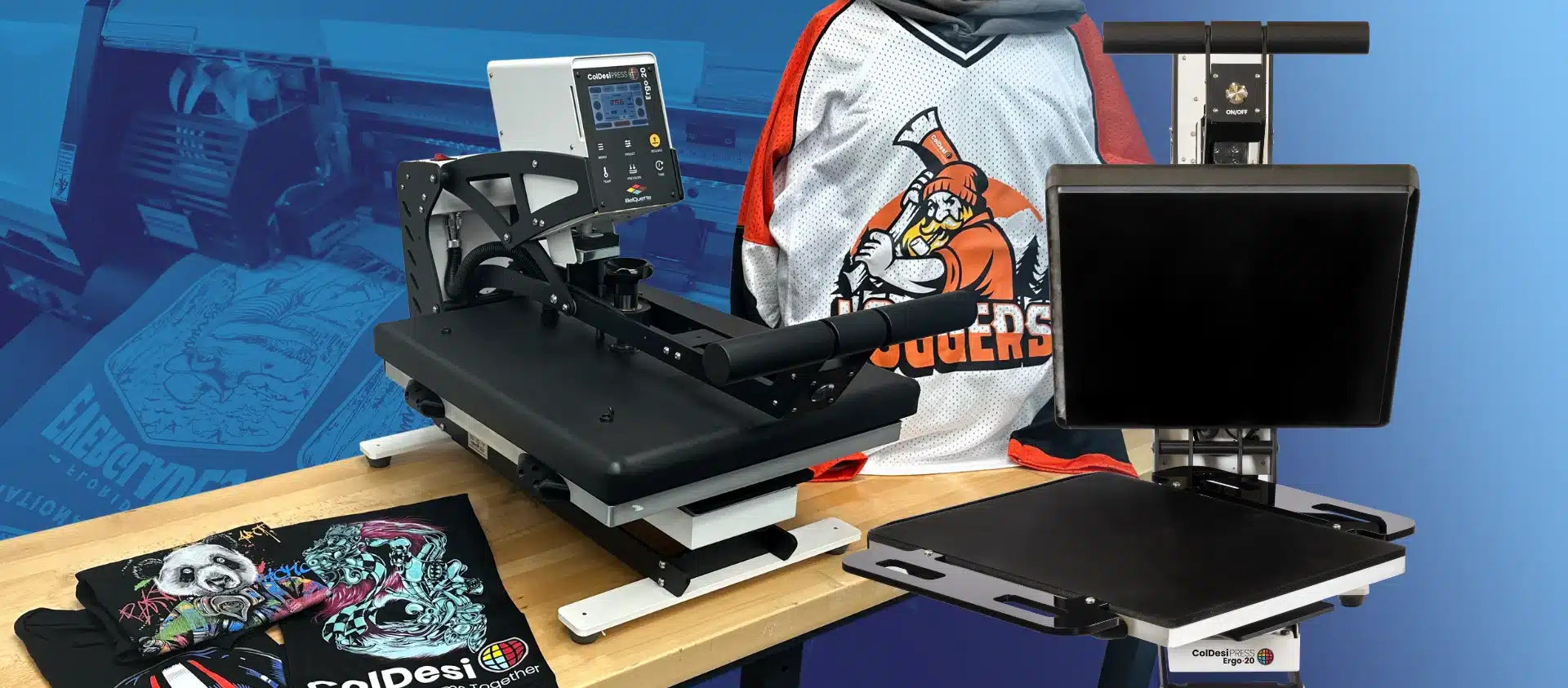

ColDesi Heat Press Solutions

ColDesi offers a full range of DTF Heat Press machines built for consistency, durability, and efficiency. Each model ensures precise time, temperature, and pressure, safeguarding the quality of every transfer.

Ergo Press – High-Volume Production

- Automated pressure system reduces fatigue

- Digital touch interface for precise settings

- IoT-enabled updates and 360° swing functionality

- Industrial-grade frame with long-term warranties

C20 Auto Clamshell Press – Mid-to-High Workloads

- Slide-out lower platen for easy garment handling

- Auto-open function for accurate cycles

- Digital scales and quick-change parts for efficiency

- Strong warranties on platen and machine

C16 Heat Press – Compact Precision

- Small footprint with A3/A4 platens

- Slide-out dressable design for easy positioning

- Even heating with less than a 5°F variance across the platen

- Interchangeable control box for simplified upkeep

Tumbler Pro Press – For Cylindrical Items

- Multiple heat platens for mugs and tumblers

- Digital controls for exact settings

- Optimized build for curved surfaces

Cap Pro Press – Specialized for Headwear

- Curved heating element for uniform results

- Adjustable pressure and digital control

- Compact and portable for frequent use

A DTF Heat Press is a critical component of the printing process. Successful transfers require precise heat and pressure to cure the adhesive layer and ensure lasting results. ColDesi heat presses are engineered to eliminate risks such as delamination, fading, and premature wear. Each model delivers accurate temperature control, consistent pressure, and dependable performance across both small-scale and high-volume production environments.

Explore how the ColDesi Ergo Press elevates workplace performance through ergonomic innovation. Its semi‑automatic system, 360° swing‑away lower platen, and automated operation reduce operator fatigue and improve safety.

DTF Heat Press Comparison

|

Press Model

|

Best For

|

Key Strengths

|

|---|---|---|

|

Ergo Press |

High-volume production |

Automation, IoT features, ergonomic design |

|

C20 Press |

Medium-to-large operations |

Even heat, auto-open, durable build |

|

C16 Press |

Compact setups |

Small footprint, consistent heating |

|

Tumbler Pro Press |

Drinkware and tumblers

|

Multi-size platens, precise controls

|

|

Cap Pro Press |

Caps and headwear |

Curved platen, portability, digital control

|

Tips for Successful DTF Transfers

- Preheat the Substrate – Always preheat the garment or substrate before applying the transfer. This step removes moisture and smooths out wrinkles, creating a clean, even surface for better adhesion.

- Use Quality Transfers – Invest in high-quality DTF films, inks, and powders from trusted suppliers. Inferior materials can compromise vibrancy, wash resistance, and the overall professional appearance of the finished product.

- Test Settings Before Production – Perform test applications on sample fabrics to verify the correct time, temperature, and pressure. Small adjustments made during testing prevent costly errors in large production runs.

- Follow Manufacturer Peel Instructions – Each transfer type has specific requirements for peeling. Some films require hot peeling for a seamless finish, while others need to cool before removal. Following these instructions preserves color integrity and ensures a smooth result.

The DTF Heat Press is the final and most decisive step in producing high-quality direct-to-film transfers. It determines how well designs bond to the substrate, how they hold up through repeated washing, and how vibrant the colors remain over time. Selecting the right press is essential for improving production efficiency, reducing costly errors, and protecting the overall quality of your products.

ColDesi’s lineup of DTF Heat Press machines are engineered for professional use. Each model delivers precise temperature control, consistent pressure, and long-term durability. This ensures businesses of all sizes can achieve repeatable, reliable results across every production run.

To learn more about how ColDesi heat presses can support your business, fill out the form below or call 877-793-3278 to speak with a specialist today.