What is Direct to Film (DTF) Printing?

DTF Printing, or “Direct to Film” Printing is a T-Shirt Transfer Printing process.

That means the printer prints onto film media, and this print is then transferred to a t-shirt by using a heat press.

A DTF printer uses liquid ink to print digital transfers. These prints work similar to any other liquid ink printer you may have used for your home or business. The difference is the type of ink, inclusion of white ink and what happens next.

With anywhere from 2 to 4 print heads in a high volume DTF printer, this means that there is one printhead that prints color ink, while another printhead prints out a layer of white. These highly accurate print heads allow for full-color digital images to be printed all in a single pass.

No Layering, No multi-step process, No mixing of ink, No need for multiple colors of film.

In order to create a transfer after printing your design, you will need to apply adhesive. DTF printing uses powder glue in order to create the transfers. Depending on your printer, the adhesive is either applied after you’ve printed and trimmed the design or as part of the full in-line process. The powder glue is moisture-seeking, so it draws into the printed ink and creates an extremely strong adhesive for shirts.

The adhesive needs heat to officially bond with the ink & film to create a transfer. This heat is either applied using a heat press, or with an in-line system.

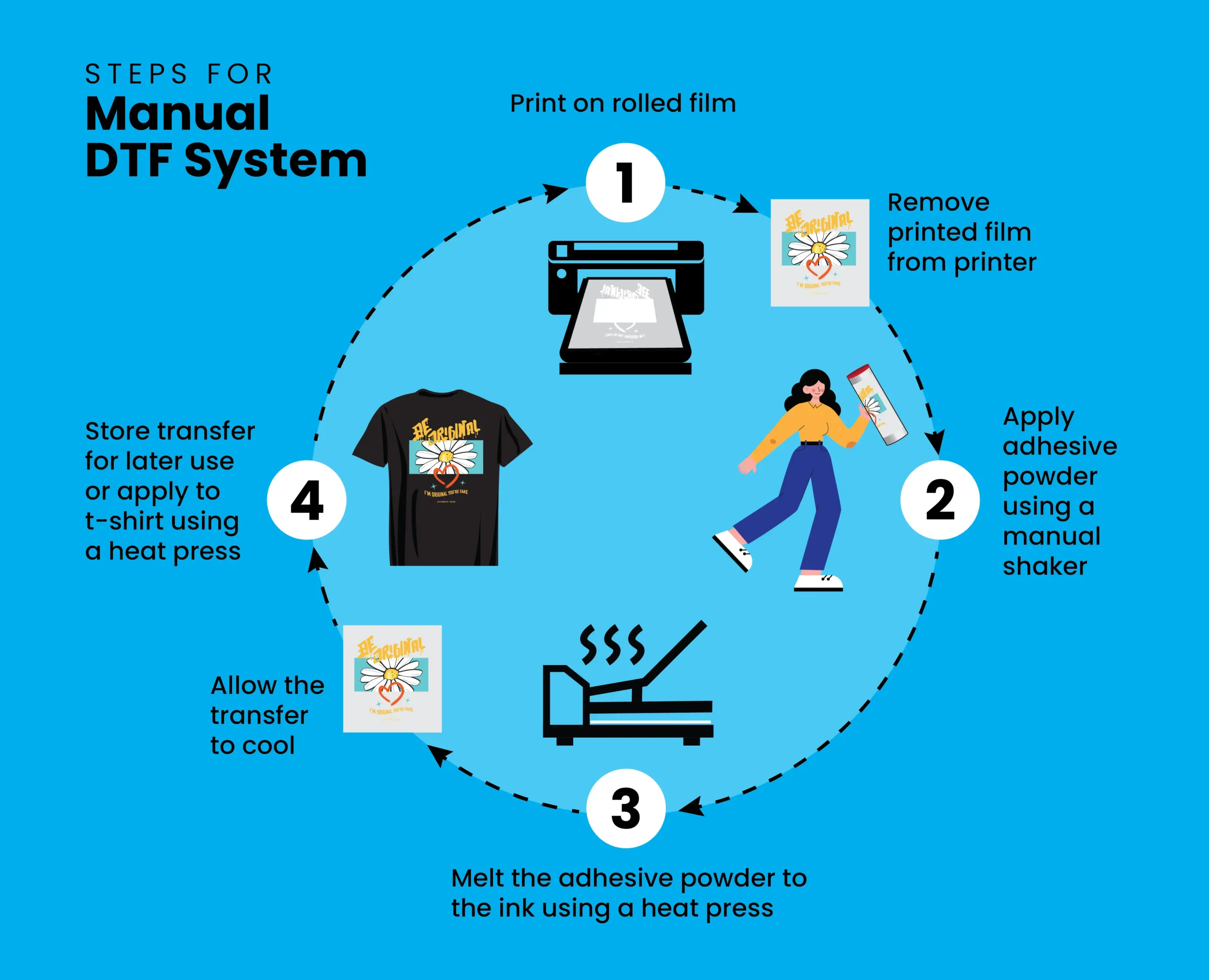

- Print on rolled film

- Remove printed film from printer

- Apply adhesive powder using a manual shaker

- Melt the adhesive powder to the ink using a heat press

- Allow the transfer to cool

- Store transfer for later use or apply to t-shirt using a heat press

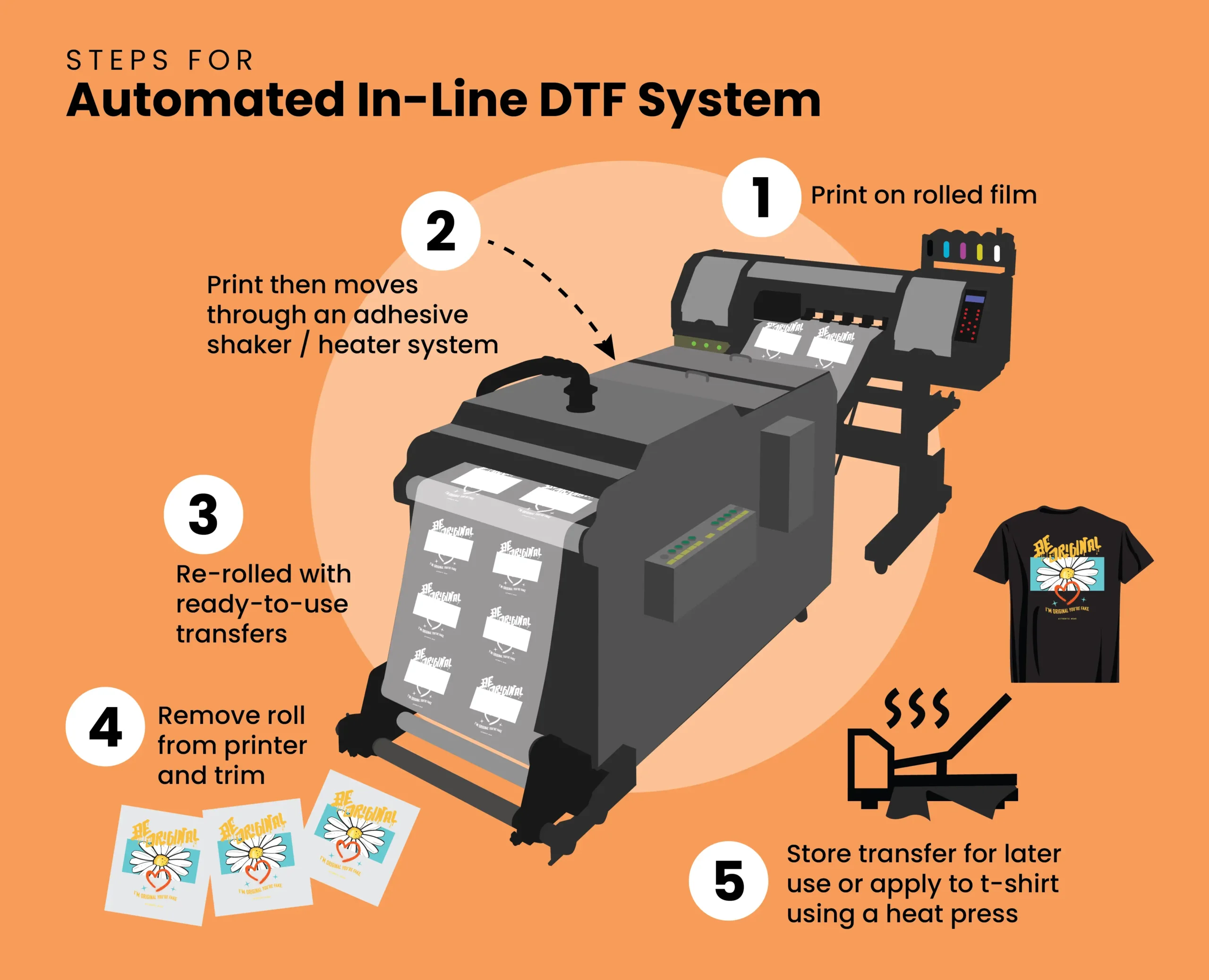

Steps when using an automated in-line DTF System

- Print on rolled film

- Print then moves through an adhesive shaker/heater system

- Re-rolled with ready-to-use transfers

- Remove roll from printer

- Store transfer for later use or apply to t-shirt using a heat press

When compared to methods like Screen Printing, a lot of businesses are adopting DTF printers for their high volume orders. DTF Printing has a lot of benefits compared to screen printing.

DTF vs Screen Printing

- No Screens

- Minimal manual labor of ‘pushing’ ink

- Setup takes minutes not hours

- No need for a Darkroom

- No measuring and mixing inks in order to properly match colors.

- No need to store or re-purpose screens

- More eco-friendly

- All colors printed in one pass

- Much easier to train staff

- One machine (and a heat press) complete the entire process

- Opens a wholesale market for you to sell transfer

DTF vs Vinyl Cutting

- No weeding

- All colors in one print

- No Layering

- No storage of multiple rolls of colored material

- Digital vs analog process

- Faster production time

DTF vs Vinyl Cutting

- No weeding

- All colors in one print

- No Layering

- No storage of multiple rolls of colored material

- Digital vs analog process

- Faster production time

DTF vs DTF

- Faster production

- Wholesale market for finished transfers

- Lower cost per print

- No pretreat of t-shirt required

DTF vs White Toner

- Faster production

- Lower cost per print

- More stretch

- Larger color gamut

- Softer hand

DTF vs Sublimation

- Works on lights and darks

- Can transfer to cotton, poly & blends

- Larger wholesale marketing for versatile transfers

- Prints white ink