Why Incorporate UV DTF?

The UV DTF Printing Technology was developed as an improvement to UV printing and to overcome its limitations.

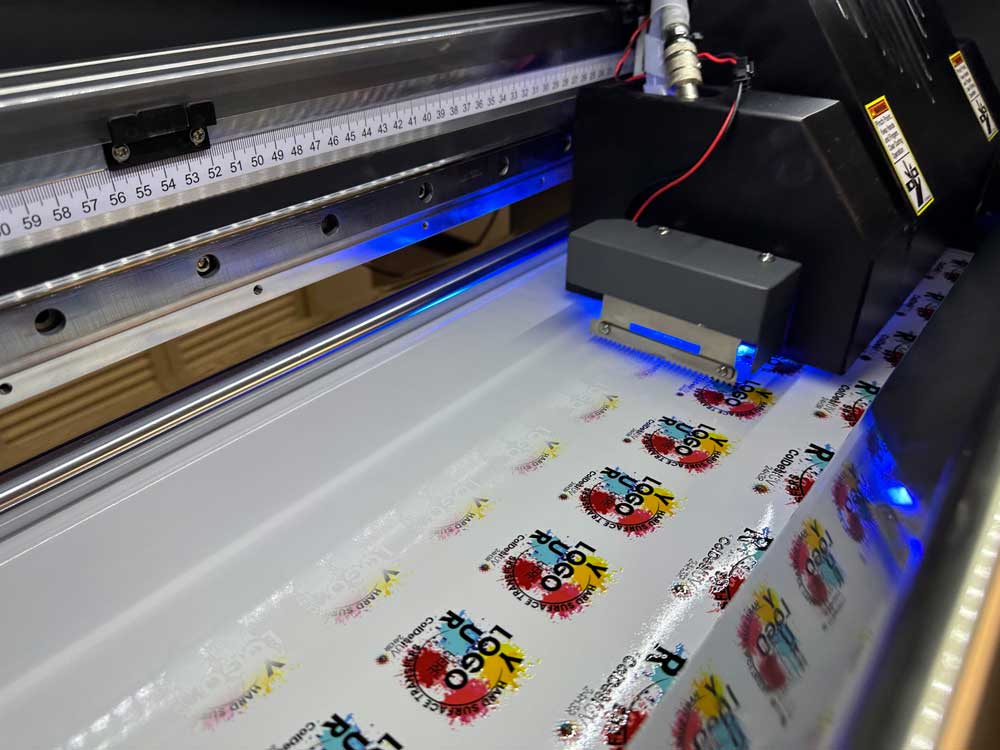

This printer produces UV DTF hard-surface transfers that can be placed onto a variety of surfaces outside of what a normal UV Printer can handle. Designed for mass production, the UV DTF printer creates high-quality transfers that are almost three-dimensional and that easily adhere to almost any surface.

No longer limited by size or shape, UV DTF printing allows your business to take on a whole new level of customization.

So, why should you think about incorporating UV DTF printing into your business?

- Mass Production Roll-to-Roll Capacities

- Ability to Print Variable Data

- High-End High-Quality Detailed Designs

- Easy Application Process

- Aggressive/Durable Adhesive Qualities

- Versatility In Shape, Size, & Surface

What Are UV DTF Transfers?

An UV DTF (Direct-To-Film) transfer uses a digital printing technique involving UV-curable ink and a strong adhesive backing. Unlike UV printing directly onto a substrate, UV DTF printing allows you to print onto an adhesive media creating a sticker like transfer that is instantly cured.

The UV DTF printing technology design is then removed from the adhesive media and can be applied. This type of transfer is great for irregular shaped products, curved surfaces, and ultra-tall or exceptionally large placement areas that otherwise may not be possible to print on.

Mass Produce UV DTF Transfers

UV DTF printers, like the 24H3R, can produce a finished product in 2-5 minutes and with no restrictions on mass production.

These machines are made for large production roll-to-roll runs. With UV DTF Printing, businesses do not need a minimum order quantity to maximize return on investment, so any print job of any size is on the table.

Print Variable Data With UV DTF Transfers

Production speed makes UV DTF technology ideal for producing variable data transfers like, bar codes, serial numbers, expiration dates, and so on. The ability to print variable data means that certain factors can be changed between each transfer of an active print job.

This can range from adding different names to transfers made for cups all the way to generating QR codes for machinery.

Incredible Visual Appeal of UV DTF Transfers

UV DTF Transfers Have an Easy Application Process

Aggressive and Durable Adhesive Qualities of UV DTF Transfers

Versatility of UV DTF Transfers

UV DTF printing eliminates the restraints of conforming to substrates that only fit a certain size, shape, or width. These transfers adhere to flexible materials, ridged media, and various surfaces like acrylic, glass, leather, paper, metal, steel, aluminum, PVC, crystal, stone, alloy, ceramic, wood, corrugated cardboard, plastic, reflective film, oil canvases, etc.

UV DTF printing stands out as an exceptionally versatile solution for customizing a diverse range of items. Its straightforward application process, coupled with the capacity to apply transfers to numerous surface types, print variable data, and create professional-grade transfers, positions UV DTF Printing as the leading choice for hard-surface customization.

Learn more about the ColDesi UV 24H3R Direct to Film Printer.

To learn more about ColDesi’s complete line of customization solutions visit our coldesi.com and Live Chat with a Pro below or call 877.793.3278.