Spot gloss UV printing transforms ordinary designs into tactile, eye-catching pieces. It selectively applies a high-gloss UV coating to specific areas of a design. This technique adds texture, depth, and sophistication that standard printing methods cannot match. Spot gloss UV printing is a powerful way to leave a lasting impression.

ColDesi Flatbed UV Printers deliver exceptional precision and versatility. This article explores spot gloss UV printing, including its advantages and recommended techniques. Learn how ColDesi’s UV printers simplify the process of adding raised, glossy elements to designs.

What is Spot Gloss UV Printing?

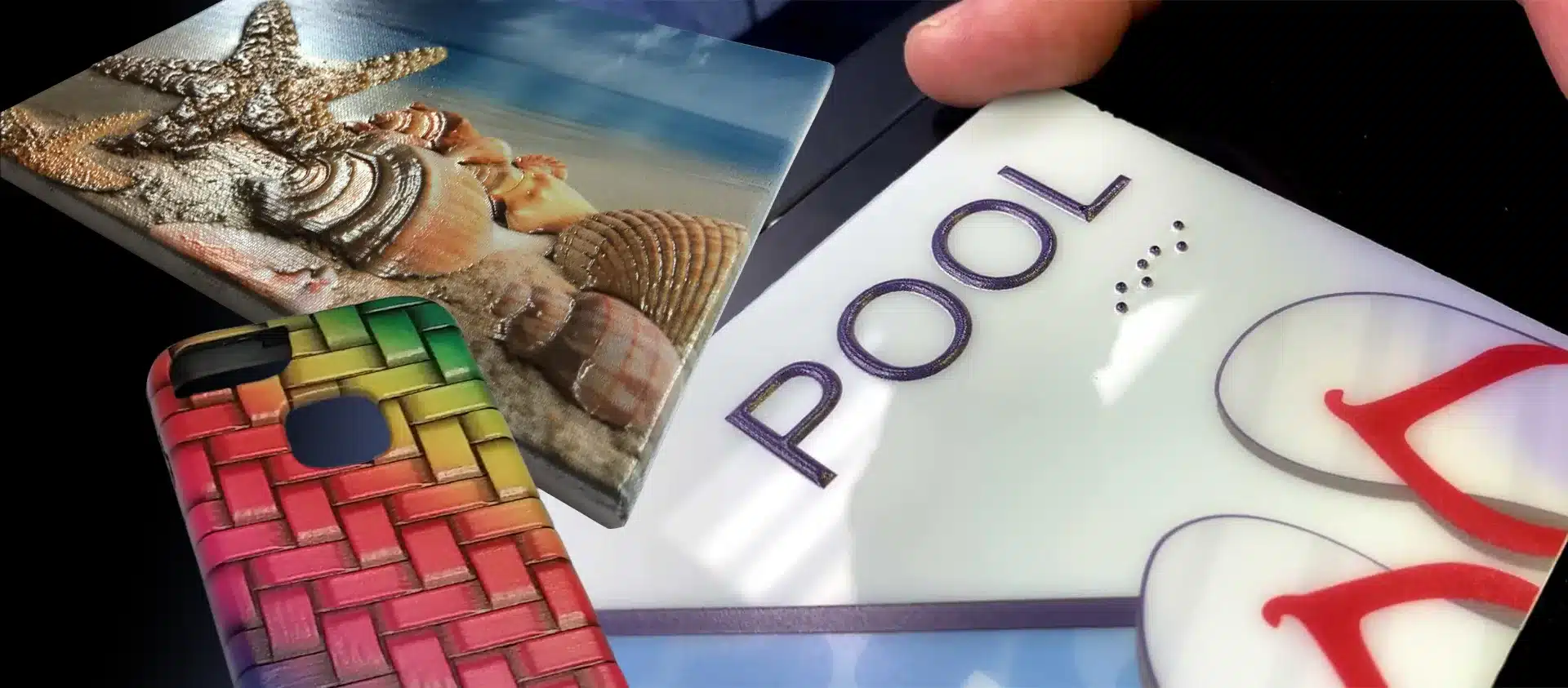

Spot gloss UV printing uses UV technology to apply a glossy coating to selective areas of a design. Spot gloss can be layered to create raised textures, giving printed materials a dimensional, tactile quality. This makes it effective for highlighting logos, text, patterns, or key visual elements.

The process involves precise application of UV gloss to specific design areas, followed by instant curing using UV light. The result is a high shine, raised finish that enhances the visual and physical appeal of the product.

The Benefits of Spot Gloss UV Printing

Spot gloss UV printing is an advanced printing technique. It offers a variety of advantages and is a powerful option for businesses aiming to enhance their printed materials. One of the key benefits of spot gloss is its ability to enhance visual appeal. A glossy, raised layer can be selectively applied to specific parts of a design. This technique creates a striking contrast against matte or uncoated surfaces. The sharp distinction highlights key elements like logos, text, or images. As a result, these features stand out prominently and capture immediate attention.

It enhances the tactile experience of printed materials. The raised, glossy textures created by this technique add a physical dimension, inviting customers to engage with the print in a hands-on way. This interaction makes the material more impactful, appealing to both sight and touch. For businesses, this multi-sensory appeal strengthens customer connections and leaves a lasting impression.

Spot gloss UV printing also offers eco-friendly advantages. The UV coatings used in this process are solvent-free. They do not emit volatile organic compounds (VOCs) during curing. This makes it a more sustainable option compared to traditional coating methods, and it aligns with the increasing emphasis modern businesses place on environmentally responsible practices.

Durability is another key benefit of spot gloss UV printing. The gloss coating forms a protective layer that resists scratches, moisture, and fading, ensuring the printed material remains in excellent condition, even with frequent handling. This is great for packaging, direct mail, and promotional items that endure wear and tear.

Efficiency is also a significant advantage. UV curing technology allows for near-instant drying when exposed to UV light. This eliminates the extended drying times of traditional printing methods, allowing for the production of high-quality results with precision, even under tight deadlines. Spot gloss UV printing is ideal for time-sensitive projects without compromising quality.

Despite its premium appearance, spot gloss UV printing is surprisingly cost-effective. It provides a high-end look and feel without the expense. It is a practical choice for businesses aiming to enhance their materials and final products while staying within budget.

Factors to Consider When Using Spot Gloss UV Printing

1. The Printing Material

The substrate plays a significant role in the outcome of spot gloss. Smooth, coated materials such as matte or glossy paperwork are best for achieving crisp, raised effects.

- Recommended Materials: Coated cardstock, PVC, acrylic, and specialty matte lamination.

- Considerations: Uncoated paper or rough surfaces may absorb the gloss unevenly, requiring more preparation.

2. Design Considerations

Spot Gloss UV is most effective when used to emphasize specific design elements. Consider highlighting:

- Logos

- Key text (e.g., company names or taglines)

- Borders and patterns

- Key imagery or areas of focus

Pro Tip: Less is more. Overusing gloss can dilute its impact. Strategically select focal points for the largest effect.

3. Desired Outcome

The effect of spot gloss UV can vary depending on your goals:

- Premium and Bold: High gloss finishes on matte backgrounds create a striking contrast.

- Subtle and Sophisticated: A more restrained approach can add texture and elegance without overpowering the design. Consider how the technique aligns with your project’s goals, audience, and branding.

4. Budget and ROI

Spot gloss UV printing may increase production costs, but its ability to enhance visual and tactile appeal often justifies the investment.

Consider:

- How it enhances brand perception

- Its impact on customer engagement and retention

- The potential return on investment from premium packaging or printed marketing materials

Creative Applications for Spot Gloss UV Printing

Spot gloss UV printing can enhance a wide range of printed materials, including:

- Business Cards

- Custom Packaging

- Brochures and Flyers

- Postcards and Invitations

- Specialty Applications

Spot Gloss UV Printing offers creative possibilities for more specialized uses:

- Matte-Finished Materials with Raised Gloss: The contrast between matte surfaces and raised gloss creates a high-end, striking effect, ideal for materials like brochures, business cards, and packaging.

- Textured Patterns for Packaging Boxes: Adding textures and patterns enhances the tactile experience, giving luxury goods or specialty items an upscale feel.

- Layered Effects for Marketing Collateral: Layered, multi-dimensional effects elevate corporate brochures, catalogs, and event programs, giving them a distinctive and professional appearance.

Spot gloss adds visual interest and tactile sophistication, helping businesses deliver impactful, memorable print materials.

Why Choose ColDesi Flatbed UV Printers for Spot Gloss UV Printing?

Spot gloss UV printing can enhance a wide range of printed materials, including:

1. Precision and Versatility

The 300H3F and 500H3F UV printers provide exceptional accuracy, ensuring that spot gloss layers align perfectly with the printed design. Their versatility allows you to print on a wide range of materials, including:

- Coated paper (matte or glossy)

- PVC and acrylic

- Specialty substrates

2. Multiple Layering Capabilities

ColDesi’s printers apply multiple layers of UV gloss to create varying heights of raised effects. This enables dramatic textures that captivate visually and tactilely.

3. Fast and Efficient Production

ColDesi’s UV printers feature instant UV curing, allowing for rapid production without compromising quality. Businesses can meet tight deadlines while delivering premium results.

4. Durability and Protection

The UV-cured gloss not only enhances aesthetics but also provides a protective layer that is resistant to scratches, fading, and moisture, ensuring long-lasting results.

5. Cost-Effective Solution

ColDesi printers offer a cost-effective way to achieve luxury finishes. Integrating spot gloss adds value to products without breaking the budget.

Elevate Your Designs with Spot Gloss UV Printing

Spot gloss is an effective way to enhance printed materials with raised glossy textures. This technique adds sophistication and visual appeal, making it ideal for business cards, packaging, and promotional items. It captures attention and helps brands stand out.

ColDesi printers make achieving professional-grade spot gloss finishes straightforward. Using spot gloss UV printing transforms ordinary designs into exceptional creations. It captivates customers with dimensional details that create a lasting impression.

Elevate your printed materials with the precision and sophistication of spot gloss UV printing. Discover how ColDesi’s UV printers can help your business stand out. Visit our website to live chat with a Pro or call 877.793.3278.