A Look at UV Printing Technology:

What It Is & How It Works

What if you had someone to guide you through everything you need to know about UV printing? You’d get the exact answers you’re looking for to questions like, ‘What is it?‘ and ‘How does it work?‘

But beyond just answering those basics, imagine having a resource that simplifies all the complex stuff to a beginners’ level.

Like, what you stand to gain from upgrading (or switching) to UV printing, and the advantages it offers over traditional methods.

Well, lucky for you, we’re here to help and will cover this (and more) right in this article.

On this page, you’ll learn about the practical uses and applications of UV printers, including what items you can print on with them and how you can customize those items.

By the end of this read, we’ll also guide you on how to choose the right UV printer for yourself or your business, and where to buy one.

There’s a lot to cover, so we better get going.

What is UV Printing?

Let’s ease right into it and start it off with the basics: “What is UV printing?”

At its simplest, UV printing is a type of printing technology that uses a combination of ultraviolet (UV) light, and UV-curable inks to print directly onto an object or a transfer film.

The key component here is ultraviolet (UV) light. Inside every UV printer, there are several UV lamps that emit this light to dry and cure the ink.

The moment the ink makes contact with the surface, the UV lamps immediately expose it to UV light. This exposure then triggers a chemical reaction in the ink, causing it to harden or cure almost instantly.

This quick curing process means the ink dries rapidly, adhering to the surface it’s printed on.

The result? High-quality, durable prints on a wide range of materials, all without the need for a heat press or waiting for inks to air-dry, as you would with traditional printing methods.

And a big plus is that the UV printing process is considered more environmentally friendly than that of other methods. Why? For starters, UV printing typically uses UV-curable inks, which contain fewer volatile organic compounds (VOCs) and fewer harmful chemicals. This makes it safer for both the planet and the people handling the prints.

Additionally, UV printing generates less waste thanks to its efficient curing process. Also, the absence of heat in the curing process reduces energy consumption.

And so when you put all of this together, it paints a very clear picture for why UV printing is considered an innovative leap in the digital printing industry.

Now, let’s take it up a notch and walk you through how this process works.

How Does UV Printing Work?

Now that you know what UV printing is, the next logical question is: “How does UV printing work?”

You might already be starting to piece together the whole process… but… let’s step back and refocus for a moment.

To fully understand the UV printing process, we must start at the very beginning and work our way through.

So, below, we’ve listed the steps in order to show how everything fits together and works as a whole.

This overall view helps you see the big picture, making it easier to understand how different parts of a system or process are connected.

1. Design Creation: It all starts off with a blank canvas. You’ll start from scratch and create your own design using graphic design software like Adobe Photoshop, Illustrator, CorelDRAW, or similar programs if you want to print something unique and personal. You can either design it yourself, hire a professional, or purchase a ready-made design online. The key is to ensure the design is print-ready with the correct color mode, resolution, and dimensions.

2. Choosing the Material: The next step is to select the substrate (material) you’ll print on, along with its shape and color. Depending on the material, it might need to be cleaned or treated before printing.

3. Printer Setup: With your design and material ready, you’re almost set to print. The next step is to transfer your design to the printer and make sure it’s loaded with UV inks. Once that’s done, position the substrate on the printer’s bed.

4. Printing: With everything set up as outlined above, you’re now ready to hit “print” and let the magic happen. First, the printer’s software takes the digital file you prepared and converts it into a series of precise instructions for the print head. The UV printer then moves its print head over the material, depositing UV-curable ink onto the surface. As the ink is applied, powerful UV lamps are activated to cure it immediately.

5. Quality Control: Finally, inspect the printed substrate for any defects such as misprints, misalignments, smudges, or other inconsistencies. If necessary, adjust the printer settings or the design file and run additional test prints. Once the print passes quality control, the finished product can be packaged and delivered to the end user.

So there you have it—a typical and widely accepted process for how decorators handle their print work.

Of course, the exact steps can differ from one person or workshop to another, and they can also vary depending on the make and model of the UV printer and the type of substrate you’re working with.

That said, what we’ve laid out here closely reflects the real-life approach that many decorators use. In practice, while the details may change, the core principles remain fundamentally the same.

Now that we’ve gone over what UV printing is and how it works, let’s take a look at the key benefits of UV printing technology.

To further your learning and knowledge about UV printing and how it works, read this. —>

Key Benefits of UV Printing Technology

Everyone’s talking about UV printing for a reason! It’s not just the latest trend or craze vying for your attention—it’s genuinely the go-to choice for most product decorators, and here’s why.

Durability and Quality: Every print that comes out of the UV printer looks absolutely stunning! The colors are vibrant, the details are sharp, and the contrast is excellent. Plus, these prints are built to last. They can retain their color and appearance for years without any noticeable fading or wear.

Versatility: Decorators love the versatility that the UV printers give them, as well as the fact that you can print on a wide range of materials (plastics, glass, metal, wood, etc.).

Environmental Impact: If you’re becoming more mindful of the environmental impact of your purchases, you’ll be glad to know that UV printers lean towards the greener side of things. The inks used contain fewer volatile organic compounds (VOCs) and fewer harmful chemicals. Additionally, UV printing generates less waste thanks to its efficient curing process. Also, the absence of heat in the curing process reduces energy consumption.

Speed and Efficiency: Speed is another defining factor why decorators upgrade or switch to UV printing. To put it in simple words, UV printers significantly reduce production time. With instant curing, there’s no waiting around for ink to dry, and you can forget about heat setting altogether!

While it may not give you everything you want, it’ll definitely check a lot of boxes—so much so that you probably won’t even need to look at other options.

And that’s got to be music to your ears!

But just wait until you dive into all the things you can use a UV printer for and what you can create with it.

What Are UV Printers Used for?

Now, the part you’ve been waiting for—what exactly can you do with UV printers?

There’s virtually no limit to what you can create! You could use them for signage, packaging, promotional products, or anything else you feel like doing. The only real limit is your imagination.

To help spark ideas, we’ve put together a list of potential products that you can decorate (and even turn into a real business).

- Phone cases

- Laptop skins

- Mouse pads

- Coasters

- Panels

- Tiles

- Wooden plaques

- Acrylic signs

- Bottles

- Glassware (e.g., wine glasses, mugs)

- Metal water bottles

- Thermos cups

- Keychains

- Awards & trophies

- USB flash drives

- Notebook covers

- Canvas prints

- Jigsaw puzzles

- Skateboards

- + MORE

Did you go through the list of things you can customize and decorate?

Now, we know this isn’t the most comprehensive list out there. If you had something in mind that is a hard surface and it didn’t make it onto the list, it would likely work but you can contact us and we would be happy to double check.

But all things considered, it’s a pretty solid starting point and should get your own ideas flowing.

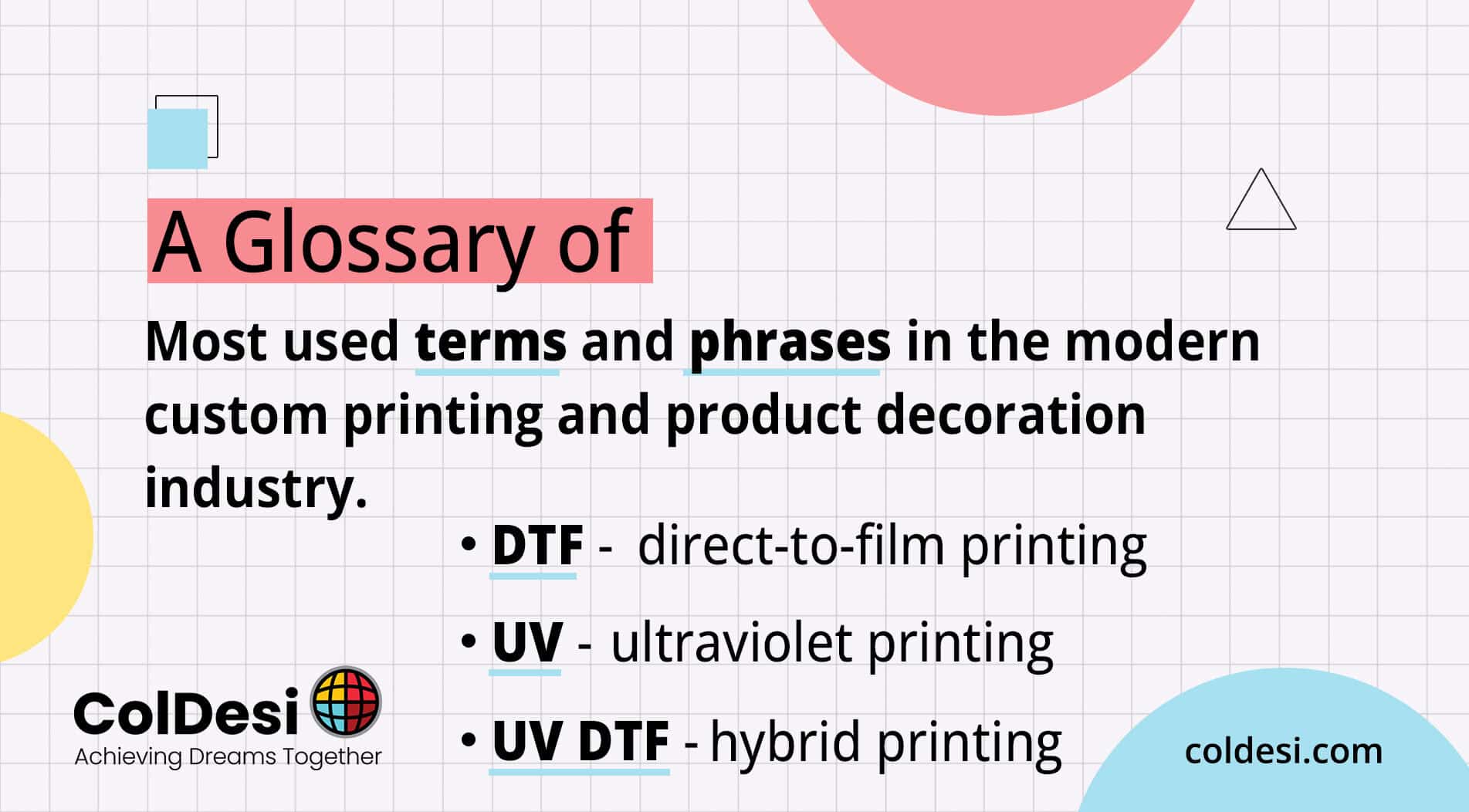

We think it’s about time to compare UV printing with more traditional methods such as screen printing, sublimation, and DTG (direct-to-garment) printing.

Comparing UV Printing with Other Printing Methods

There are so many different printing methods that you can get pulled in various directions. So, why choose UV printing over the others? What makes UV printing stand out?

Well, let’s find out the answer for this question in this section. A good place to start would be to compare UV printing with more traditional printing methods, such as screen printing, sublimation, and DTG (direct-to-garment) printing. Each method has its own set of unique applications along with benefits and limitations.

Let’s take a closer look at the similarities and differences between them.

Screen Printing: In essence, screen printing is a method where a design is transferred onto a surface using a stenciled mesh screen, ink, and a squeegee. The way it works in practice is very simple: The process begins by stretching a fine mesh screen over a frame and coating it with a light-sensitive emulsion. When exposed to light, the emulsion hardens in areas not covered by the design, forming a stencil. Ink is then spread across the screen and pushed through the open areas of the stencil with a squeegee, transferring the design onto the material below. It’s especially good for things like t-shirts, bags, pillows, and other items, but it takes a lot of time to set up and costs more if you’re only making a few. It also creates more waste with leftover ink and used screens.

Sublimation: It would be a mistake not to compare UV printing with sublimation. How do these two printing methods measure up against each other? To start, let’s remind ourselves of what sublimation printing actually is. At its core, sublimation is a process that uses heat, pressure, and specialized sublimation inks to transfer designs from sublimation paper directly onto a chosen material. The inks are initially printed onto transfer paper. Then, through a combination of heat and pressure, the design is transferred onto the material. Now, is sublimation better than UV printing? Well it’s hard to say, as both techniques have their own strengths and limitations. The choice between the two comes down to the material, desired output quality, and volume requirements.

DTG (direct-to-garment): DTG stands for direct-to-garment printing. As the name suggests, this method uses specialized inkjet technology to print your design directly onto fabric using water-based inks. It’s ideal for smaller print runs (typically up to 100 garments or more) and works especially well for designs with multiple colors or variable data. DTG printing is perfect for fabrics like t-shirts, hoodies, and other apparel. On the other hand, UV printing is better suited for hard surfaces like phone cases, plaques, promotional products, signage, and packaging.

While each printing method has its place, UV printing stands out for its ability to deliver high-quality, durable prints on a wide range of materials, all while being environmentally friendly and efficient.

But where do we go from here? While this is where things stand today, let’s take a moment to think about what the future might hold.

Future Trends in UV Printing Technology

Are there any future trends on the horizon for UV printing technology? One could only speculate on the potential developments and the exact trajectory of UV printing, but a few key trends seem to push the industry forward.

In fact, these trends have been shaping the field for quite some time.

It’s no surprise that manufacturers are likely to continue focusing on reducing curing times, increasing print speeds, and improving overall productivity.

Innovations like more energy-efficient UV lamps, lower VOC emissions, and better build quality are all contributing to these advances.

Additionally, improvements in ink formulations could enable printing on a wider range of surfaces, while making inks more recyclable or biodegradable.

And with the rise of AI, could we eventually see it integrated into UV printing? Only time will tell.

But we can say with certainty that it’s people—us humans—who set the trends and shape the future of this industry.

So, we all need to keep our eyes open for news, needs, wants, desires, and behaviors that take place in the market and see what people are naturally gravitating towards. Everything is moving forwards at a rapid pace, so it’s up to the observers, thinkers, and note takers to spot these changes and pioneer new solutions, approaches, products, machinery, and features.

The word out there is that you can’t teach people how to think, but you can teach them what to think about.

So, in our humble opinion, it’s worthwhile to think about workflow automation for your most routine processes, consumer preferences, and how you can create the best possible product (and a community around it).

That could be a whole article on its own. So, let’s set that aside for now and keep going with the rest of the article and our final point before we wrap things up.

Choosing the Right UV Printer

With so many options for UV printers these days, how do you choose the one that checks all your boxes?

Well, one way to do that would be to cross-compare your specific needs (and project requirements) with the top UV printers on the market.

Consider key factors like price, speed, print bed size, and build quality, and weigh them against what matters most to your business.

This way, you can prioritize the features that will have the biggest impact on your workflow and bottom line.

Of course, you won’t be left on your own to figure it out. Luckily, we’ve just put together a guide to the best UV printers on the market right now.

So, perhaps a good starting point for you would be to have a quick read through that material.

In it, we looked at 5 UV printers—ColDesi UV 24H3R, 300H3F, 500H3F, and the Mutoh XpertJet 461UF and 661UF series! For each one, we worked out their intended use, features, performance, and price, so you can easily compare them and make an informed decision.

Need help choosing which UV printer is right for you? Here are our top picks! —>

Conclusion

In conclusion, is there anything more left to be said?

Well, there will always be more that we could have added to this article. But for what it is, this write-up already provides tons of information for you to work through. We could give you all the details in the world, but ultimately, the decision of which UV printer to buy rests with you.

Looking back at what we’ve covered here, we’ve looked at what UV printing is and how it works. We’ve discussed the key benefits of UV printing technology, its applications, and its best uses. We compared UV printing with more traditional methods and speculated on future developments in the field.

Finally, we wrapped things up by pointing you to a buyer’s guide to help you choose the right printer for your needs.

So, if you’re thinking about diving into custom product decoration or looking to level up your current setup, UV printing might be exactly what you need.

Here’s why:

- Instant Drying and Curing

- Exceptional Print Quality

- Durable Results

- Consistent Performance

- Versatile Substrate Compatibility

- Eco-Friendly

- Quick Turnaround Times

- Wide Market Appeal

- Stand Out from Competitors

- Expand Product Offerings

- Higher Profit Margins

- Easy to get Started

- Support & Help

To learn more about ColDesi’s line of UV printers, visit

coldesi-uvprinter.com and Live Chat with a Pro below, or call 855-201-9185.