Custom drinkware has never been more versatile, thanks to UV/DTF cup wrap transfers. From tumblers to coffee mugs, UV/DTF offers a professional, durable finish that stands out. Below are answers to frequently asked questions and information about UV/DTF. We built this guide to help you better understand the UV/DTF process and equipment, as well as the potential UV/DTF printing could bring to your business.

What Are UV/DTF Cup Wrap Transfers?

What Can You Put UV/DTF Wraps On?

UV/DTF cup wrap transfers can be applied to a wide variety of smooth, hard surfaces, including:

- Stainless steel tumblers

- Glass cups and jars

- Acrylic and plastic drinkware

- Candle jars

- Ceramic mugs

- Metal containers

- Automotive surfaces

- Wood signs (sealed)

What Can UV/DTF Stick To?

Can You Put UV/DTF on Tumblers?

UV/DTF printing makes it easy to personalize Yeti cups, mugs, and tumblers. With the ColDesi 24H3R, you can print detailed, adhesive-backed transfers that apply without heat, weeding, or masking. Read: Creating Customized Yeti Cups, Mugs, and Tumblers with UV DTF | ColDesi 24H3R

How to Transfer UV/DTF Cup Wraps

- Clean the surface with alcohol to remove dust and oils.

- Peel the UV/DTF transfer from its backing film.

- Align and press it onto the surface, starting from the center outward.

- Use a squeegee or firm pressure to remove any bubbles.

- Slowly peel away the carrier film.

How to Put UV/DTF Stickers on Cups

Ensure the surface of the item you wish to customize is clean and dry. Align your design carefully and apply even pressure across the entire transfer. Let it rest for several hours before use.

How to Make a UV/DTF Stick

Pressure and surface preparation are key. Wipe down your object with isopropyl alcohol. Apply the transfer using firm pressure. Avoid touching the adhesive side during alignment. Air bubbles can be removed by pressing outward with a squeegee.

Why Is UV/DTF Not Sticking to Glass Tumblers?

- Residual oils or moisture on the surface

- Inadequate pressure during application

- Textured or curved areas where the wrap doesn’t sit flush

Why Is My UV/DTF Peeling?

- The surface wasn’t thoroughly cleaned

- The design wasn’t pressed down firmly enough

- The object is exposed to moisture too soon

How Long Does UV/DTF Last on Cups?

UV/DTF decals are also built to last—resistant to fading, washing, and scratches, thanks to UV-cured inks that bond tightly to film. Read: The Longevity and Durability of UV DTF Decals

Does UV/DTF Last Longer Than Vinyl?

Is Vinyl or UV/DTF Better?

Is UV/DTF Just a Sticker?

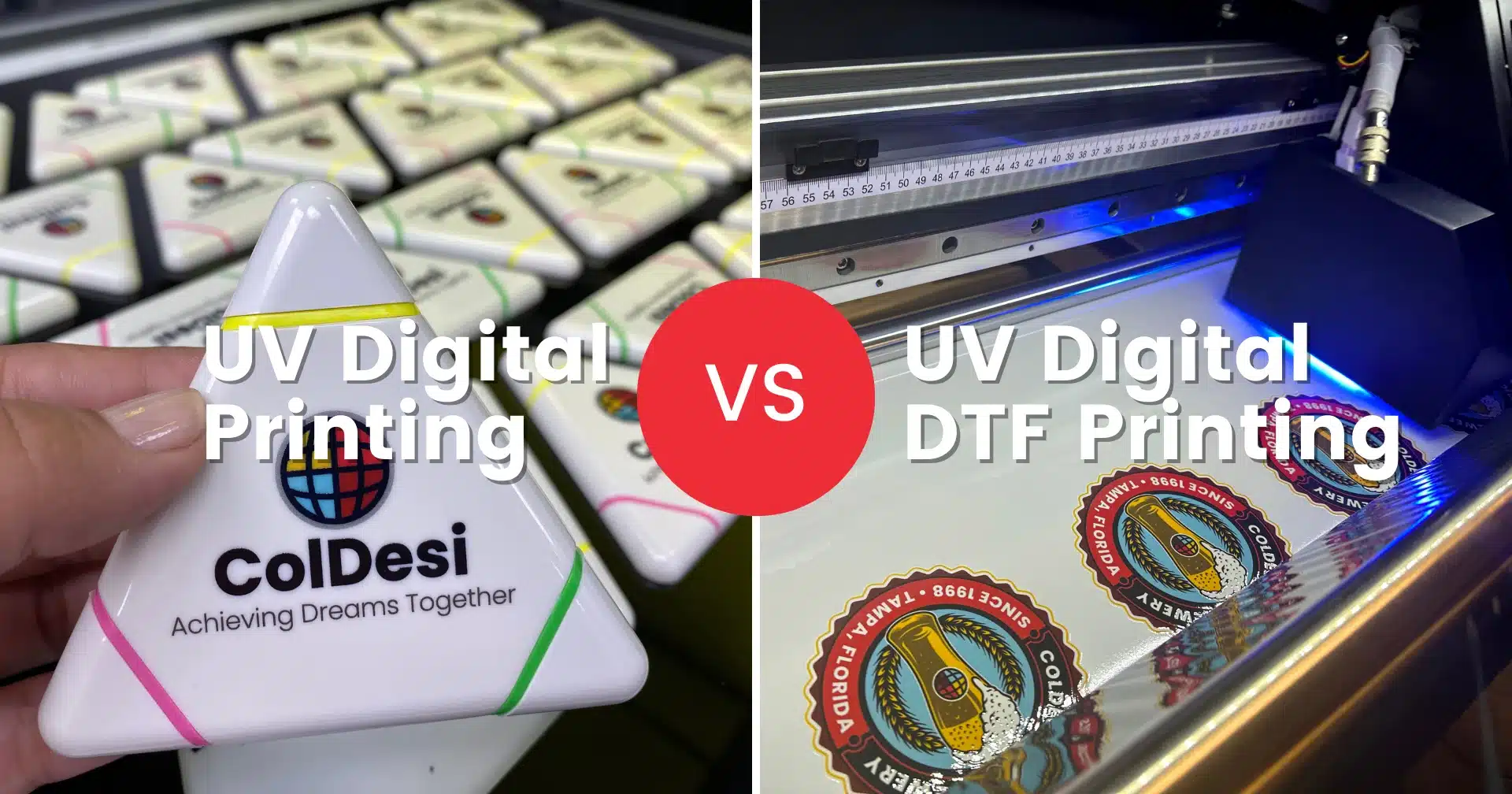

What Is the Difference Between UV/DTF and DTF?

- UV/DTF: Designed for hard surfaces (cups, glass, acrylic). No heat press needed.

- DTF (Direct-to-Film): Made for fabric printing. Requires a heat press and adhesive powder.

Want to understand the difference between UV and UV/DTF printing? Read: Differences Between UV Digital Printing and UV DTF Digital Printing

What Is the Difference Between UV/DTF Wrap and Sublimation?

|

Feature

|

UV/DTF Wraps

|

Sublimation

|

|---|---|---|

|

Surface Compatibility |

Smooth, hard surfaces |

Polyester or poly-coated only |

|

Application Method |

Peel-and-stick |

Heat press + high heat |

|

Colors |

High vibrancy |

High vibrancy |

|

Equipment Required |

UV printer + film |

Sublimation printer + heat press |

Does UV/DTF Fade?

Can UV/DTF Go in the Dishwasher?

Do You Have to Cure UV/DTF Cup Wraps?

Do You Need a UV Light for UV/DTF Wraps?

Does UV/DTF Need a Heat Press?

What Do You Need to Print UV/DTF Transfers?

- A UV/DTF printer (such as the ColDesi 24H3R)

- UV-curable inks

- Transfer film (A/B type or laminate film)

- RIP software to manage print layout and color profiles

- A laminator is needed if not integrated into the printer

- High-resolution artwork

What Ink Is Used for UV/DTF?

What Size Are UV/DTF Cup Wraps?

- 9.3" x 4" for 20 oz tumblers

- 10.2" x 5" for 30 oz tumblers

Can You Print UV/DTF on a Regular Printer?

How to Print UV/DTF Cup Wraps at Home

You will need a UV/DTF printer. Here’s the basic workflow:

- Design your wrap in a vector or high-resolution raster format.

- Print the design onto film using UV-curable ink.

- Laminate the printed film (if a laminator is not integrated into the printer).

- Cut and apply to the target surface.

Can You Cut UV/DTF Wraps?

How to Get a UV/DTF Off a Tumbler

- Soak the tumbler in hot, soapy water.

- Gently peel or scrape with a plastic tool.

- Use an adhesive remover for any residue.

To explore ColDesi’s UV/DTF printing solution or to speak with one of our product experts, fill out the form below or call 877-793-3278.