For new business owners venturing into the printing industry, it’s critical to choose the best UV DTF printer you can find to secure long-term success.

The right printer will provide high-quality prints that stand out in a crowded market, garnering customer satisfaction and repeat business.

"Moreover, top-tier UV DTF printers are often more efficient and durable, leading to lower operating costs over time. "

The best UV DTF printers will also come with better support and warranty options, safeguarding your investment.

Therefore, the choice of UV DTF printer can significantly influence your business’s profitability and reputation.

Understanding UV DTF Technology

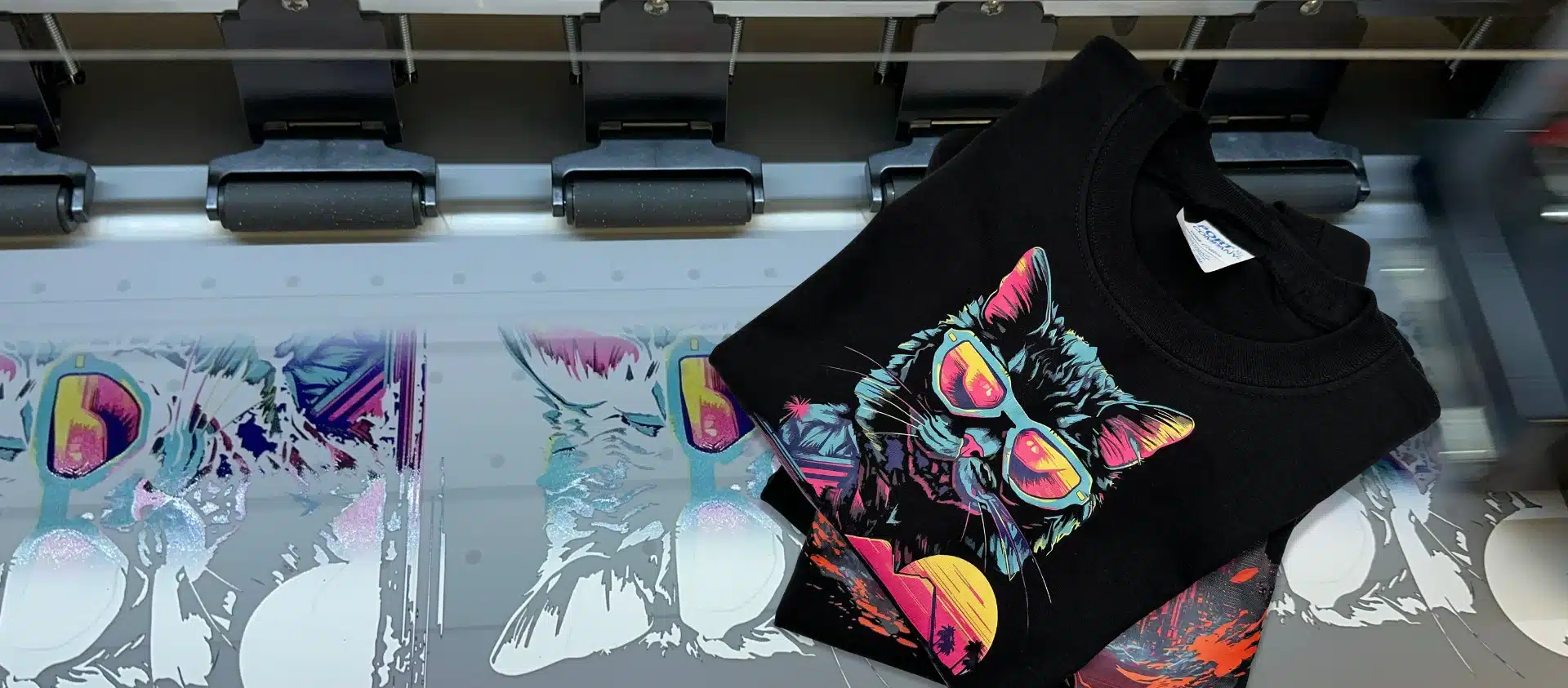

UV DTF (Direct to Film) printing is a highly advanced printing technique that allows for high-quality, full-color prints to be transferred onto various substrates, such as fabric, wood, ceramic, and more.

Unlike traditional UV printing, which necessitates the item to fit into the machine, UV DTF printing involves printing onto a special film first, which is then transferred onto the product – WITHOUT the need for heat or special equipment to make the transfer stick!

The Adhesive Revolution in UV DTF Printing

One significant innovation that has permitted the advancement of UV DTF technology is the evolution in adhesive use. The UV DTF process utilizes a strong adhesive film that the ink is sprayed onto in layers.

"This incredible process removes the size and shape constraints of the traditional method, delivering the best UV DTF printer solution."

With its exceptional color vibrancy and long-lasting performance, it’s no wonder that businesses prefer it for creating visually impactful products. Specifically, the best UV DTF stickers shine through with their sharp, vivid images and impressive durability, elevating any product they adorn.

Steps to the UV DTF Process

-

The design is loaded into the software, and optimized for high resolution (300 dpi or better). It includes a transparency layer to ensure seamless integration with any background and crisp edges that guarantee no blushing or blurring occurs on the edges, maintaining the design's sharpness and clarity.

-

The Rip software works seamlessly to separate colors into individual layers and channels, carefully determining the precise amount of ink to allocate to each channel of the print head. This meticulous color separation process ensures accurate color reproduction and vibrant prints that capture every detail.

-

In order to maximize the usable area of the adhesive roll for printing, the software efficiently organizes multiple designs. By strategically arranging the designs, it minimizes waste and maximizes efficiency, resulting in a more cost-effective and streamlined production process.

-

The designs are meticulously printed in layers on the adhesive "A" roll, starting with a solid white base. This base layer acts as a foundation, ensuring that the subsequent colors appear vivid and true to the original design. Each color is carefully applied, ensuring precise registration and vibrant hues. Lastly, a layer of varnish is added, providing a protective and glossy finish that enhances the overall visual appeal.

-

To ensure a secure and durable bond between the ink and adhesive, the printed stickers, decals, or logos are subjected to the power of UV lamps. These lamps emit ultraviolet light that cures the ink almost instantly, penetrating through the varnish and ink layers. This curing process creates a strong and resilient bond, ensuring that the design remains intact even under harsh conditions.

-

In the final step, the finished stickers, decals, or logos pass through an on-board laminator. This process adds an additional layer of protection and durability to the UV DTF transfers, ensuring that they are ready for application and capable of withstanding the test of time.

Considering the intricate steps involved in the UV DTF process, investing in the best machine is paramount. The complexity of the technique demands precision, efficiency, and durability – traits found in top-tier UV DTF printers.

With a high-quality printer, you can ensure that each step, from design optimization to lamination, is executed flawlessly. This results in high-grade transfers that won’t get rejected due to inaccuracies or subpar quality. Remember, an inferior printer might compromise on the output, leading to potential losses and damage to your brand reputation.

Applications of UV DT

- Personalized Accessories

- Home Decor

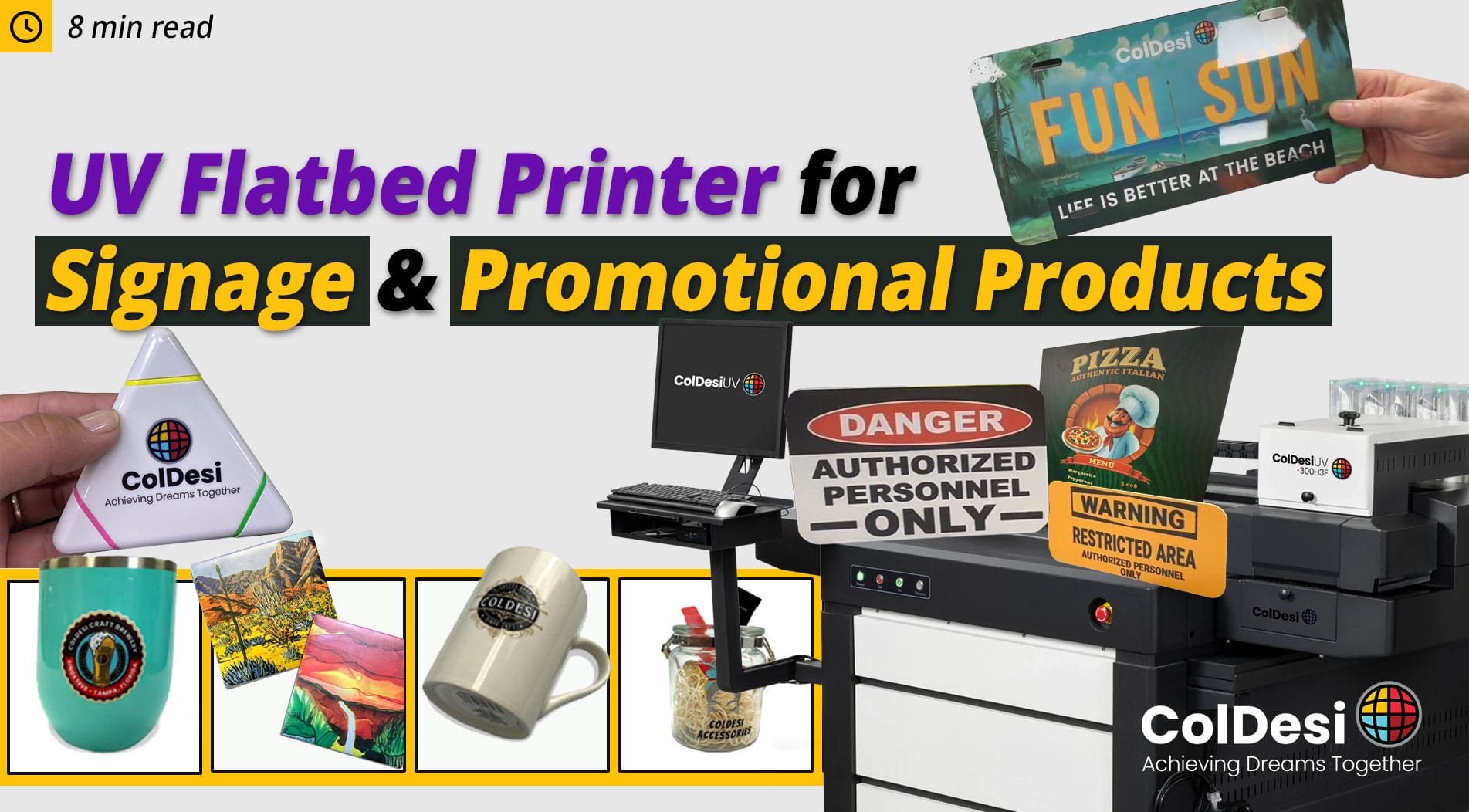

- Signage

- Product Packaging

- Promotional Products

- Art Prints

- Stationery

- Wedding Favors

- Corporate Gifts

- Party Supplies

- Branded Merchandise

- Customized Jewelry

- Personalized Gifts

- Event Decor

- Custom Stickers

- Customized Mugs

- Branding Solutions

- Custom Keychains

- Custom Tote Bags

- Personalized Stationery

- Custom Labels

- Custom Raised Print Magnets

Tips for Successful UV DTF Printing

Choosing the best UV DTF printer requires a comprehensive analysis of several factors.

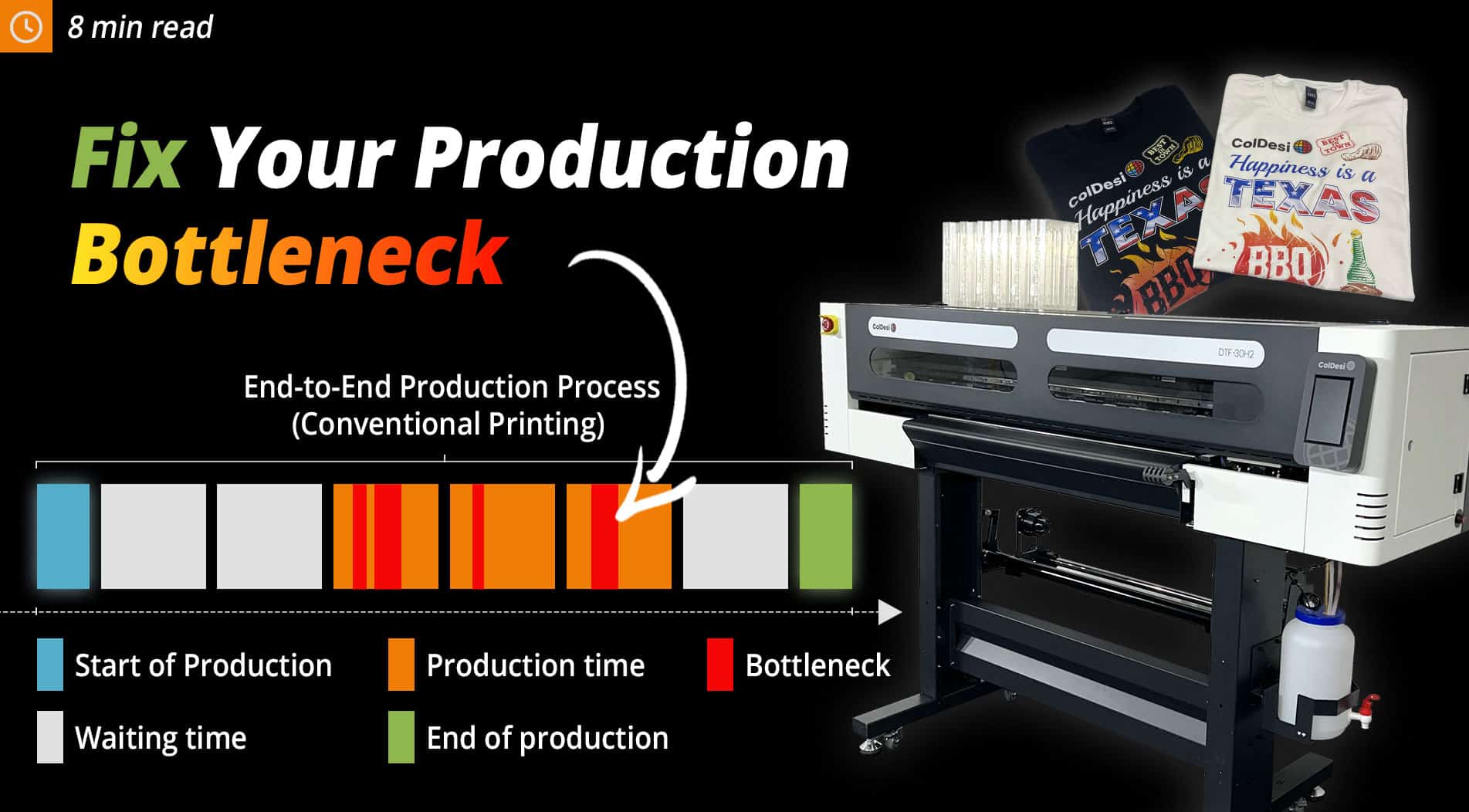

While it might be tempting to save money by choosing a cheaper UV DTF printer, this can often be a false economy. Inexpensive printers can lead to subpar print quality, frequent breakdowns, and higher long-term costs due to maintenance and replacement parts.

In the competitive world of printing, quality and reliability are vital – a cheap printer could end up costing more in lost business and frustration than the savings on initial cost. Therefore, it’s crucial to consider the total value and potential return on investment of a high-quality UV DTF printer when making your decision.

"Like you, your customers will notice cheap print quality if you invest in a cheap printer. They just will."

-

Printer Quality and Performance: A crucial aspect to consider is the printer's quality and performance. Research the printer's resolution, color vibrancy, print speed, and overall print quality. Ensure that it aligns with your business requirements and customer expectations

-

Reliability: Check the printer's reliability. A dependable printer will have fewer breakdowns and maintenance issues, ensuring constant uptime for your business operations.

-

Service and Support: Investigate the service and support options provided by the manufacturer. Look for a company that offers comprehensive support, including technical support, troubleshooting, and regular maintenance services.

-

Company Reputation: Consider how long the company has been in business and its reputation within the industry. A company with a long history in the printing industry is likely to have refined its technology and customer service over time.

-

Warranty: The warranty offered by the company is also a critical consideration. It can protect your investment against any potential defects or issues with the printer.

-

Price: Lastly, compare the printer's price with other options available in the market. Ensure that you are getting a good balance of price, quality, and service.

By carefully considering these factors, you can select the best UV DTF printer to maximize your printing efficiency and increase your business’s success.

Features to Look for in a UV DTF Printer

Key Features for Top Performance

When it comes to optimizing the performance and outcome of prints, several key features play a crucial role. Let’s dive into a detailed discussion about these advantages:

-

Print Resolution: The level of detail and sharpness in prints can be greatly influenced by the resolution settings. Higher resolution results in more precise and accurate prints.

-

Print Speed: The speed at which a printer can produce prints is an important factor to consider. Faster print speeds can save time and increase productivity.

-

Material Compatibility: Different printing materials require specific settings and considerations. Ensuring compatibility between the printer and the chosen materials is essential for achieving optimal results.

Other Advantages that make UV DTF printers the Best.

-

No weeding required; what you print is precisely what gets transferred.

-

Eliminates the need for multiple layers of art, as seen in screen printing or vinyl cutting.

-

Achieves faster output compared to eco-solvent printers and other technologies.

-

Simplifies the process with a single step, eliminating labor-intensive tasks.

-

Reduces the reliance on messy or hazardous materials, particularly in large-scale screen printing.

-

Offers the versatility to print using White and Clear ink with just one transfer film.

-

Allows printing on clear or white vinyl materials, alongside the DTF transfer film.

"Having evaluated all the features and technology that goes into the best UV DTF printer you can buy. We believe the ColDesi 24H3R UV DTF printer is the best one you can buy right now."

Creative Applications of UV DTF Printing

Custom Christmas Ornaments

Cups, Mugs and Tumblers: Custom Drinkwear!

The Future of UV DTF Printing Technology

Innovations and Trends

Using UV DTF printers is a great way for businesses to create tons of unique gifts and promotional items.

You can personalize accessories, home decor, branded merchandise, and event decor with ease. When choosing a UV DTF printer, make sure to consider factors like printer quality, reliability, company reputation, warranty, price, and service and support.

Don’t forget to check out the top-performing printers with features like high print resolution, speed, material compatibility, and unique capabilities. This article also briefly touches on the latest trends and future prospects of UV DTF printing, showing that this technology is here to stay.

As UV DTF printers continue to evolve, they’re becoming the go-to solution for large-scale, high-quality, and diverse printing applications. Get ready for a new era of customized prints!

To learn more about ColDesi’s complete line of customization solutions visit our coldesi.com and Live Chat with a Pro below or call 877.793.3278.