ColDesi recently recorded a webinar focused on the advantages of UV and UV/DTF printing. It highlights how businesses can transition from traditional methods to more profitable production solutions.

The webinar walks through current limitations in traditional decoration workflows. It explains how today’s demand for full-color, high-resolution printing is driving businesses to invest in new technologies. Learn how UV and UV/DTF open new possibilities for customization. These technologies help reduce production time. They also offer a greater return on investment through faster turnaround. Plus, they enable broader product capabilities.

Explore equipment options suited for different business sizes. Learn about real-world applications that create new revenue opportunities—from promotional items to retail signage to durable branded goods. This is a must-watch for businesses considering equipment upgrades, expanding into hard goods, or seeking more control over their production processes.

From Legacy to Leading-Edge

Learn more about the limitations of traditional methods still used in production environments. Techniques like vinyl cutting limit both color options and design complexity. This makes them less effective for detailed or multicolor work.

Sublimation works well in some cases, but it’s restricted to polyester-based and light-colored materials. That significantly reduces its versatility.

Pad printing requires manual setup. It often leads to inconsistent results—especially with small batches or intricate designs.

Screen printing is widely adopted but has drawbacks. It comes with high setup costs, long preparation times, and is inefficient for multi-color or short-run jobs.

As demand grows for fast, full-color, high-resolution output on a variety of surfaces, these older technologies can’t keep up. This webinar shows how UV and UV/DTF printing fill that gap. They offer a modern, efficient alternative for decorators and manufacturers today.

What UV and UV/DTF Printing Brings to the Table

UV and UV/DTF printing offer practical solutions for businesses seeking quality, speed, and material versatility. UV printers deliver full-color, high-resolution images that cure instantly under ultraviolet light. This eliminates the need for drying time and significantly increases durability and efficiency. UV/DTF technology expands on this by allowing designs to be printed and then transferred onto curved surfaces. This is useful for customizing items like tumblers, bottles, and complex hard goods.

The webinar highlighted several key benefits of these technologies. UV and UV/DTF printers support a wide range of materials including wood, acrylic, glass, metal, and plastics. Their fast production speed—made possible through instant curing—helps reduce turnaround time. With minimal setup requirements and consistent output across various applications, these technologies offer a strong return on investment for both new and established businesses.

Equipment for Every Type of Business

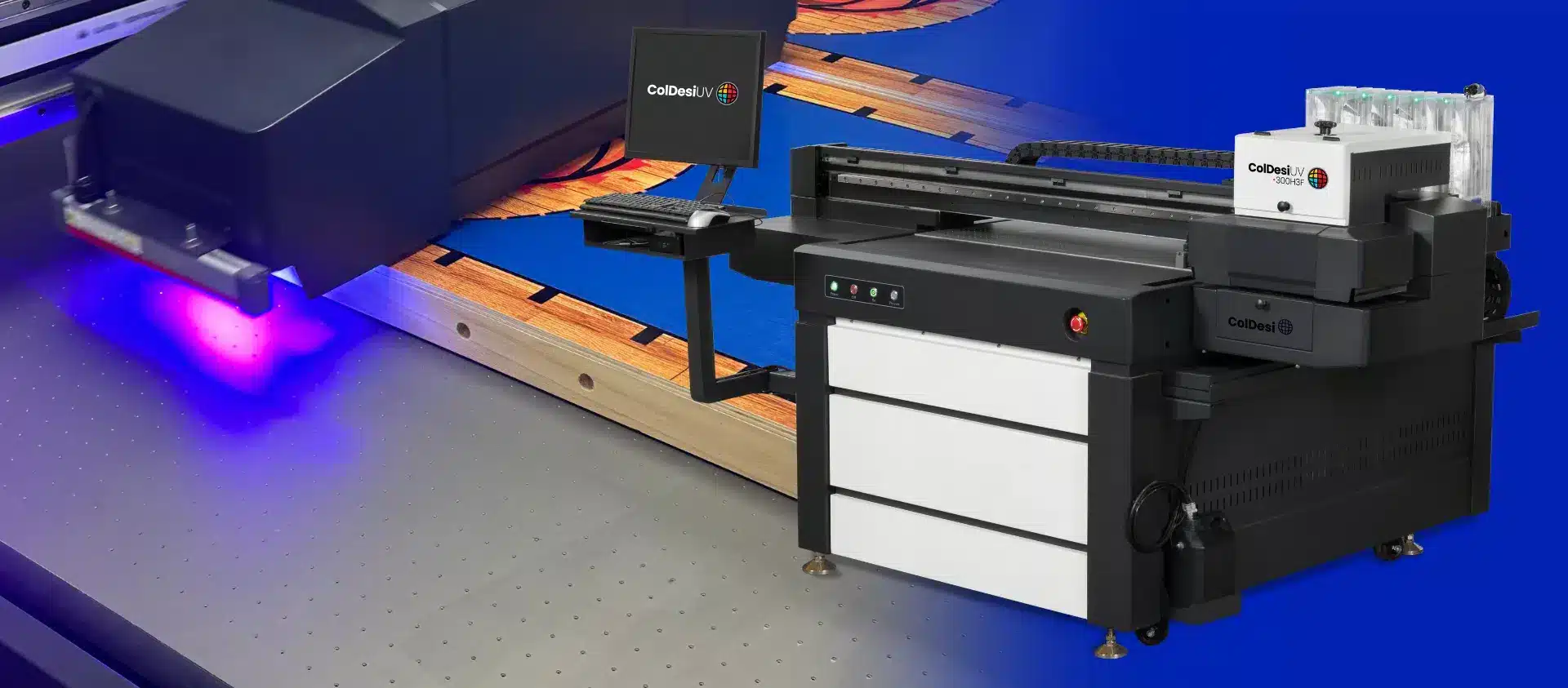

The webinar introduced UV printers tailored to meet the needs of a wide range of businesses. ColDesi offers high-volume printers designed to deliver scalability and efficiency in production environments.

ColDesi’s UV and UV/DTF printer lineup includes:

Who Benefits from UV and UV/DTF Printing

This technology is practical for both small and large operations. Businesses looking to profit, reduce outsourcing, or grow new product categories will benefit from upgrading their equipment.

Production teams seeking to increase speed, output and substrate versatility will find that UV and UV/DTF deliver across the board.

For those already using screen printing or sublimation, UV and UV/DTF are logical next steps in expanding capabilities and improving production efficiency.

Real-World Applications That Drive Growth

A key part of this webinar focuses on how UV and UV/DTF printing can be applied to grow real businesses. These technologies give businesses the ability to print full-color, high-quality graphics directly onto hard goods or transfer sheets, reducing the need for outsourcing. This allows businesses to gain more control over production and improve turnaround times.

It covers a range of high-impact applications, including custom promotional items, retail signage, and branded hard goods. UV/DTF printing also supports the creation of durable outdoor labels, which are ideal for products that require long-lasting performance in challenging environments. This highlights the profitability and versatility that UV technology brings to today’s customization businesses.

See how UV/DTF printing is opening new doors for custom product makers. This article covers the benefits, from vibrant designs to easy application on hard surfaces. It’s a smart option for growing your customization business.

Read More

A Clear Path Forward

This webinar will give you a clear understanding of how UV and UV/DTF printing technologies are transforming the industry. These solutions help businesses streamline production and expand their product offerings. They also solve many of the challenges tied to traditional methods.

If your company is thinking about an upgrade or looking to stay competitive, UV and UV/DTF are worth exploring. They are practical, scalable, and offer strong potential for profit.

Ready to See What UV and UV/DTF Can Do for Your Business?

Do not miss the opportunity to learn how UV and UV/DTF printing can streamline your production, open new product lines, and boost profitability.

Take the first step toward modernizing your printing operation with technology built for today’s market demands. Fill out the form below to learn more about ColDesi’s line of UV and UV/DTF printers.