Create Custom Sublimation Socks

Sublimation socks, celebrated for their vivid and whimsical patterns, offer enduring style and resilience.

As everyday wear leads to natural wear and tear, the demand to customize sublimation socks rises. The advanced sublimation technique ensures that each design remains impeccable, resistant to the rigors of stretching, snug shoe fits, and repeated laundering. This process guarantees that your unique sock designs stay vibrant wash after wash, meeting the market’s need for high-quality, custom-printed socks that combine personal flair with longevity.

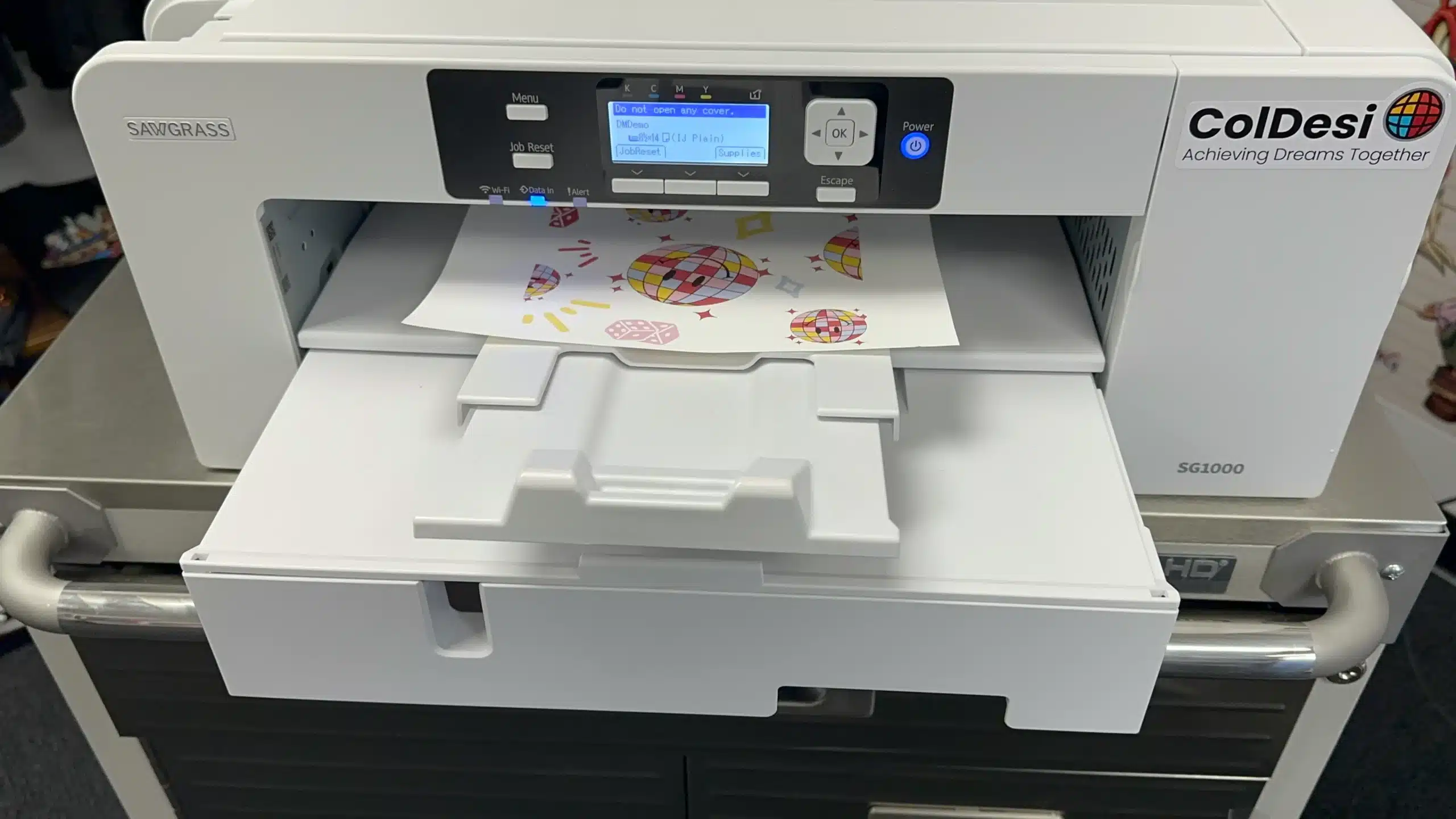

Embark on a journey into the vibrant realm of sock sublimation with the reliable Sawgrass SG1000 Sublimation Printer. Whether you’re a custom apparel decorator, or someone aiming to enhance your business profitability, this video serves as your essential guide to sublimating socks with flair and accuracy.

Supplies Needed for Sublimation Socks:

To make sublimation socks you’re going to need the supplies listed below.

How to Create Custom Socks

Everyone adores charming socks that speak volumes in the realm of fashion! Sublimation is an excellent method for crafting colorful socks. Sublimation ensures that the vibrant colors not only pop but also resist fading or peeling over time. Making for a lasting and eye-catching fashion statement.

1. Preparation: Preheat the Hotronix Fusion-IQ Heat Press. Time, temperature, and pressure settings will vary depending on fabric. (check transfer papers instructions)

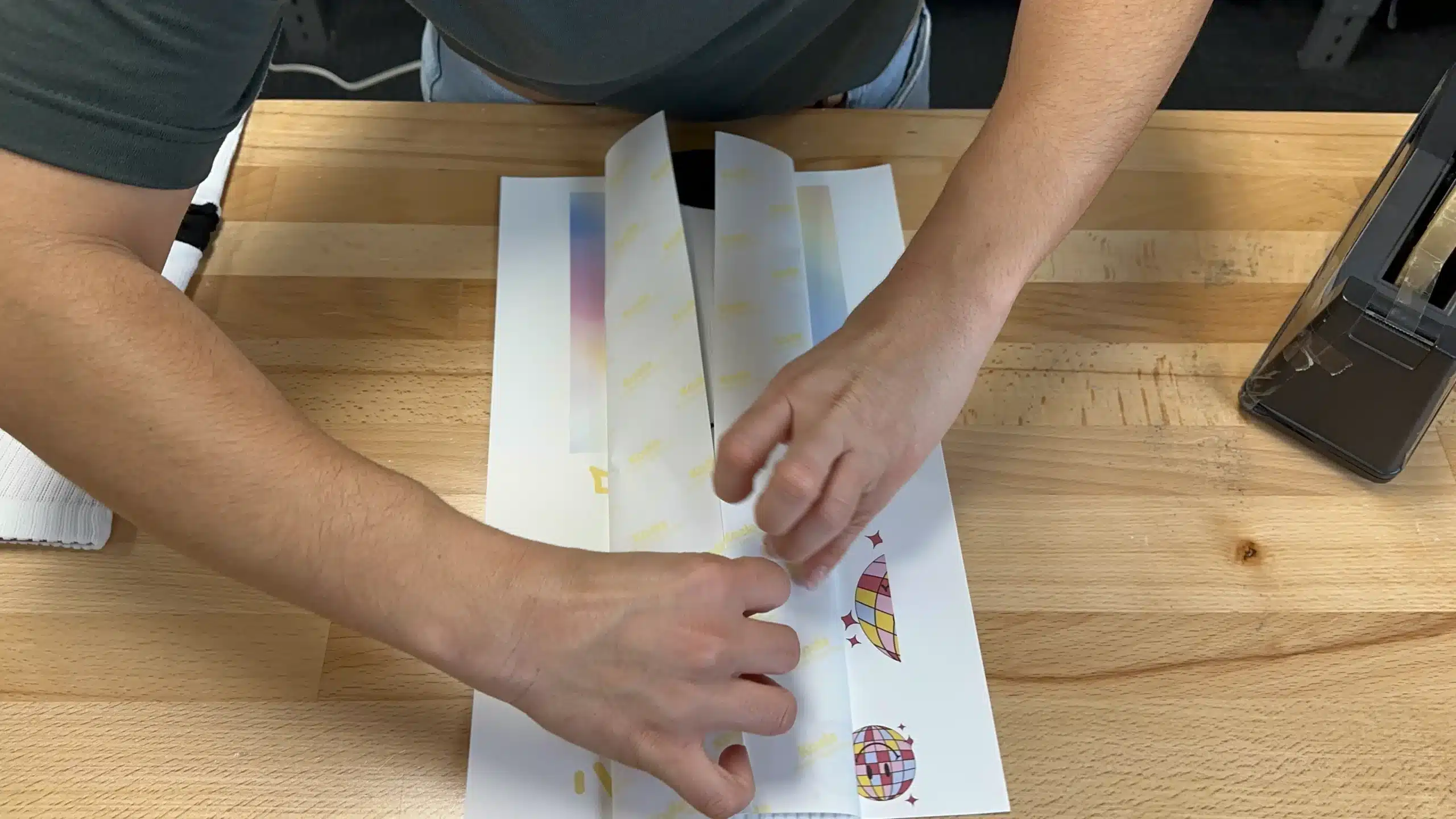

2. Printing Process: Load the design file into Sawgrass Print Manager. Format the design for print. Load your sublimation paper into your printer and print.

3. Prep socks and Design: Place the socks into the jig. Use clear heat tape to secure the printed design to the first side of each sock.

4. Pressing Process: Place the Crew SubliSocks on the Hotronix Fusion-IQ Heat Press. Place the Flexible Finishing Sheet on top, and press!