Direct To Film

NEW MODEL: Check out the BY-20

The Latest DTF Printer from Roland

All New Roland BN-20D: Desktop Direct to Film System

The Roland BN-20D takes customizing clothing to the next level without the hefty price tag!

You can create stunning full-color designs and graphics easily. This new system is made to handle even the most detailed and intricate artwork. Let your creativity soar while you create beautiful on-demand prints.

Introducing the Roland BN-20D

If you’re looking for a more compact, desktop version of a DTF printer for your shop, the answer is here! The all-new Roland BN-20D system offers the same reliability and features of Roland’s BN-20 system but with the addition of an integrated direct to film system.

Roland BN-20D Specifications

With a maximum print resolution of up to 1,440 dpi, the BN20-D provides superior image quality and detail.

Because it’s a DTF film transfer printer, you can avoid the difficult and time consuming process of weeding and masking. You will be able to print artwork with fine lines and small details unlike when working with traditional vinyl.

Additionally, it can also be used as a stand-alone vinyl cutter if needed.

How does the Roland BN-20D printer work?

Made to use with unique powder, film, and inks, the BN-20D streamlines the process of transferring graphics and text designs to blanks and apparel in a way that achieves optimal results.

The Roland BN-20D system has a maximum print width of 20 inches, eliminating the need to feed the printer sheet after sheet. You can simply load the media, send your artwork to the printer, and walk away!

This allows harried business owners the time to work on other important tasks around their shop or even complete the dtf process on transfers from a previous job.

So, how do you make dtf transfers with the Roland BN-20D?

Let’s talk about it.

In just FOUR simple steps, you can create high-quality and durable custom apparel, without any weeding or masking.

Here’s how it works:

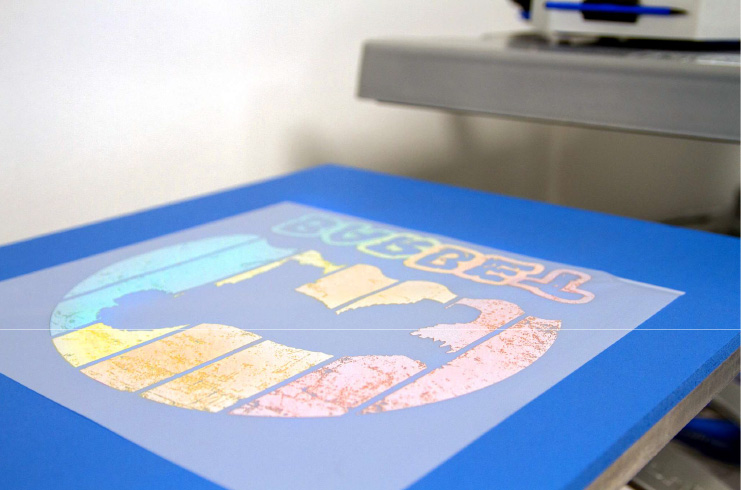

1. Print to film using the BN-20D and S-PG inks, on S-F164 transfer film.

2. Apply the S-Powder over the ink.

3. Melt the powder under a heat press for the recommended time and temperature.

4. Heat press the design or graphic to your substrate and peel the backing off like a band aid.

Advantages of the Roland BN-20D Direct-to-Film System

- DTF Capabilities – You will be able to transfer the most detailed and intricate graphics and fine text quickly and easily without having to weed or apply a transfer mask.

- Versatility – Great for multi-use, this machine can create film transfers prints but can also serve as a stand-alone vinyl cutter. It also accommodates various rolls of media outside of the Roland brand.

- Maintenance – The BN-20D requires little maintenance and can create consistent prints without having to “babysit” the machine.

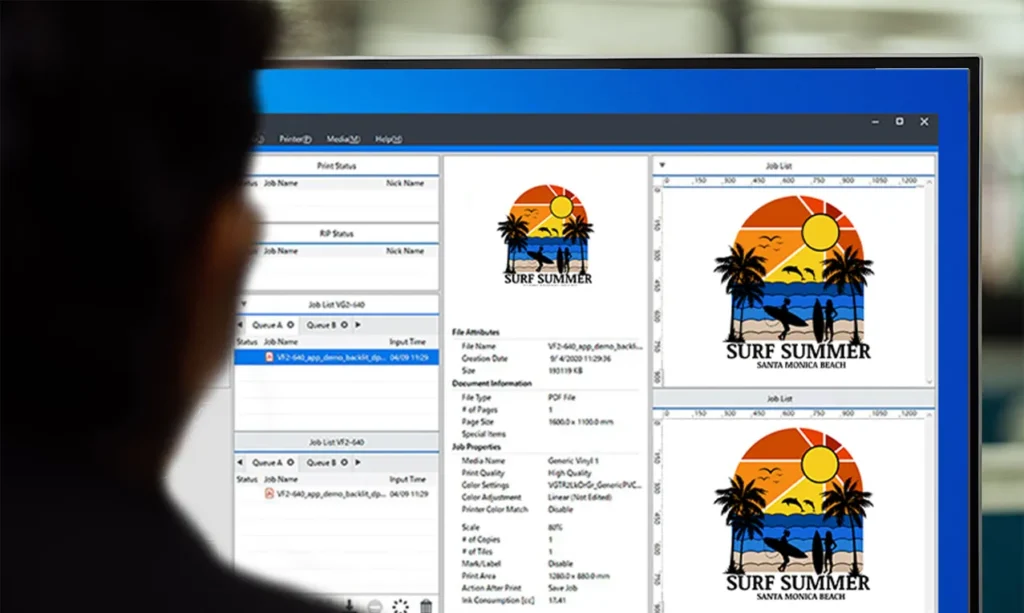

- VersaWorks 6 RIP Software – Included with the Roland BN-20D machine, this is the most powerful and intuitive software on the market.

- White Ink Regulation System – The dedicated channels for CMYK and improved white ink delivery system, help produce rich and vivid color while achieving optimal white ink opacity for light and dark colored garments.

Does It Come with Printing Software?

Absolutely, you’re going to want to make sure you’re in control of how your artwork looks! Included with this dtf film transfer printer comes VersaWorks 6 RIP software.

Engineered to make the printing process easy for users of all skill levels, this software features RIP production tools for managing all your print-and-cut output.

- HARLEQUIN RIP dual core engine and 64-bit native processing for enhanced speed and file handling.

- Add cut lines directly in the RIP— change vector data into cut line data.

- A variety of profiles designed for different types of application, enable high-quality print output without difficult settings.

- Easy drag-and-drop interface allows you to quickly add jobs to the print queue.

- Integrated spot color libraries include Pantone and Roland DG Color libraries.

- Intuitive tiling, cropping, nesting and other features that have made VersaWorks the world’s favorite software RIP.

What can you Print with the Roland BN-20D?

Because this is a multi-purpose system that can be used for dtf transfer printing and as a vinyl cutter alone, the BN-20D can customize tons of light and dark colored substrates.

Here are just some customization ideas to get you started:

- T-shirts

- Tote Bags

- Sweatshirts

- Aprons

- Backpacks

- Hats

- Polos

- Button Downs

- And Much More!

Comparison of the Roland BN-20/A (A version) and the Roland BN-20D

The Roland BN-20/A and Roland BN-20D have some similarities, the biggest and most obvious being the appearance of the machines. Although the list of similarities is quite short, we’ll discuss them briefly.

- Types of Ink

Both the BN-20 (not the BN-20A) and the BN-20D can print white ink. For the Roland BN-20D, this is used as a base on top of the full color image, producing an opaque transfer. Once the curing dtf powder is applied to the transfer, then it forms an adhesive that’s ready to be applied to your garment.

- Print Size

Another similarity between these machines is that they all can accommodate media rolls up to 20 inches wide, so it’s easy to load.

This gives you the ability to print tons of small images, designs, or logos all at once!

Differences Between the Roland BN-20/A and the Roland BN-20D

With similarities, come differences as well. Between ink colors, materials, and printing process, these machines differ greatly.

- Materials and Ink

For example, the Roland BN-20/A uses eco-solvent ink while the Roland BN-20D uses specialty inkjet ink in CMYK and white.

For the BN-20D, specialty ink, transfer film, and powder are needed in order to print dtf transfers. Otherwise, this system can be used solely as a vinyl cutter.

This means that while the Roland BN-20/A can print on vinyl, sticker paper, wall cling, canvas material and much more, the BN-20D cannot.

- Image and Graphic Set Up

When prepping artwork for the BN-20/A, contour cut lines are required for the machine to be able to make cuts after the artwork is printed.

This typically takes place in a separate software like Adobe Photoshop.

Unlike the BN-20/A, the BN-20D dtf printer doesn’t need cut lines because it doesn’t cut. However, it will require different steps in the software to start printing.

- Printing Process

When printing and cutting with the Roland BN-20/A, the art is printed first then fed back through for the cutting to take place. Once that process is done, the transfer is ready for application.

On the other hand, the BN-20D requires a few more steps. First, the color layer is printed. In a second pass, a white top layer will be printed on the image.

This dtf transfer is now ready for the powder to be applied. After the dtf powder is added to the transfer, it will need to melt under a heat press for the adhesive to bond. Lastly, it can be heat applied to a garment to create a wonderful customized product.

Because of the differences in the printing processes, Roland BN-20D transfers skip the weeding and masking process while BN-20/A transfers can’t.

Depending on your business’ needs, this will help you determine which machine is right for you.

Roland VersaStudio BN20-D

-

Integrated print/cut capabilities

-

Photorealistic printing up to 1440 dpi

-

State-of-the-art printing technology

-

Roland Intelligent Pass Control™ technology for unparalleled image quality at the highest print speeds

-

New wiper system to prolong life of the printhead, minimize maintenance, and improve image quality.

-

Desktop footprint

-

Choice of three Eco-SOL ink configurations and one four color Aqueous

-

Easy loading media system

-

R-Works™ design software included

-

VersaWorks 6 RIP Software included

-

Roland OnSupport software for remote production tracking available for download

-

One-Year Trouble-Free Warranty

Continental U.S. Only. With approved credit. Not good with any other offer.

Or fill out the form below for more info.

| Specifications | VersaStudio BN-20-D |

|---|---|

| Printer Dimensions | 39.7" W x 22.9" D x 11.5" H in. (1,009 W x 582 D x 293 H mm) |

| Max. Media Width | 20.3 in. (515 mm) |

| Max. Print Width | 18.9 in (480 mm) |

| Number of Ink Slots | 5 |

| Ink Technology | Pigment |

| Ink Capacity & Colors | 220ml cartridge - CYMK + White |

| DTF Consumables |

Film and Powder - S-F164 film & S-POWDER Cleaning Liquid - CJ-CL |

| Maintenance |

Cap Top - User replaceable Cap Top Replacement Sequence - Start from utility Wiper - User Replaceable Felt Wiper - User Replaceable Manual Cleaning - Every day after the end of the workday |

| Installation | Self Installation |