You bought that little hobby embroidery machine for the person you were back then.

At the time, it was fun, simple, and just enough to get you started.

Today you are someone different, someone aiming higher. Now you need one built for the person you are becoming.

Look, if you’re reading this, something about your current setup just isn’t working anymore. And you’re starting to notice it.

Maybe orders are piling up, taking longer than they should. Or you’re turning down work you could be taking on.

Half the time, you can’t even step away and leave this machine alone for more than five minutes without things going haywire.

Thread breaks mid-design. Stitches skip. And before you know it, your whole afternoon is spent fixing jams rather than actually finishing work.

Sound familiar?

That’s no way to get work done. And it’s definitely not how a business gets run.

That’s wrestling with a machine that’s already told you, loud and clear, it’s had enough.

Now here’s the important part: none of this means you’re doing anything wrong. You didn’t make a mistake buying that little hobby machine of yours. You just outgrew it. Plain and simple.

And sure, right about now you’re probably thinking, if only there were a solution… then all these nagging annoyances would be removed.

Good news there is one! The solution is the Avancé line of commercial embroidery machines from ColDesi.

Machines designed to run all day without constant supervision. Machines built to handle heavy workloads, multiple jobs, and long hours with ease.

In other words, machines designed for people like you. Someone who wants to actually get things done. Someone who dreams bigger, wants more, and needs equipment that won’t tap out halfway through the project.

If any of this sounds like you, don’t go anywhere.

Because by the end of this article, you’ll know:

- What separates a hobby machine from a commercial one.

- What to look for in a commercial embroidery machine.

- Which make and model actually makes sense for where you’re headed.

- Which features actually matter for real workloads.

- How to choose a setup that won’t hold you back six months from now.

- Essential supplies, tools, and accessories for your new machine

Let’s start.

Why Upgrading from a Home or Hobby Embroidery Machine Is Non-Negotiable for Business Growth

Before anything else, let’s call it like it is: a home or hobby embroidery machine will only take you so far.

There comes a point where it stops being helpful. And when you hit it, it starts costing you time, money, and opportunities.

And that’s exactly the problem we’re here to fix.

But it pays to learn why moving up from home, hobby, or semi-professional embroidery machine isn’t just a nice-to-have, it’s absolutely essential.

You see, a home or hobby machine might be fine when you’re just starting out, playing around, or doing small projects for fun.

But “fine” won’t get you to the next level, or even help you handle the backlog you have right now. ”Fine” doesn’t let you scale.”

Think about the last time your machine jammed mid-design, or the needle broke for the third time in a row, or the hoop slipped and ruined a customer’s shirt.

That’s not just a small hiccup. You just lost hours of work, materials, and maybe even a paying customer.

Every minute your machine is stuck, every design that comes out sloppy, every customer you disappoint… that’s money walking out the door.

It’s easy to tell yourself, “It’s just a hobby, I can make do…” but deep down, you know the truth. You’re stuck. Stuck with a machine that was never meant to handle high volume production runs, intricate fabrics, or multi-color embroidery.

Now, imagine for a second what it would be like to upgrade. A machine that doesn’t jam. A machine that runs for hours while you focus on other parts of your business. One that works with a variety of hoops, handles bigger designs, and automatically switches between threads, all at once.

That’s not a dream. These machines exist, and they can change the way you work.

Up next, we’ll show you which machines can take you there.

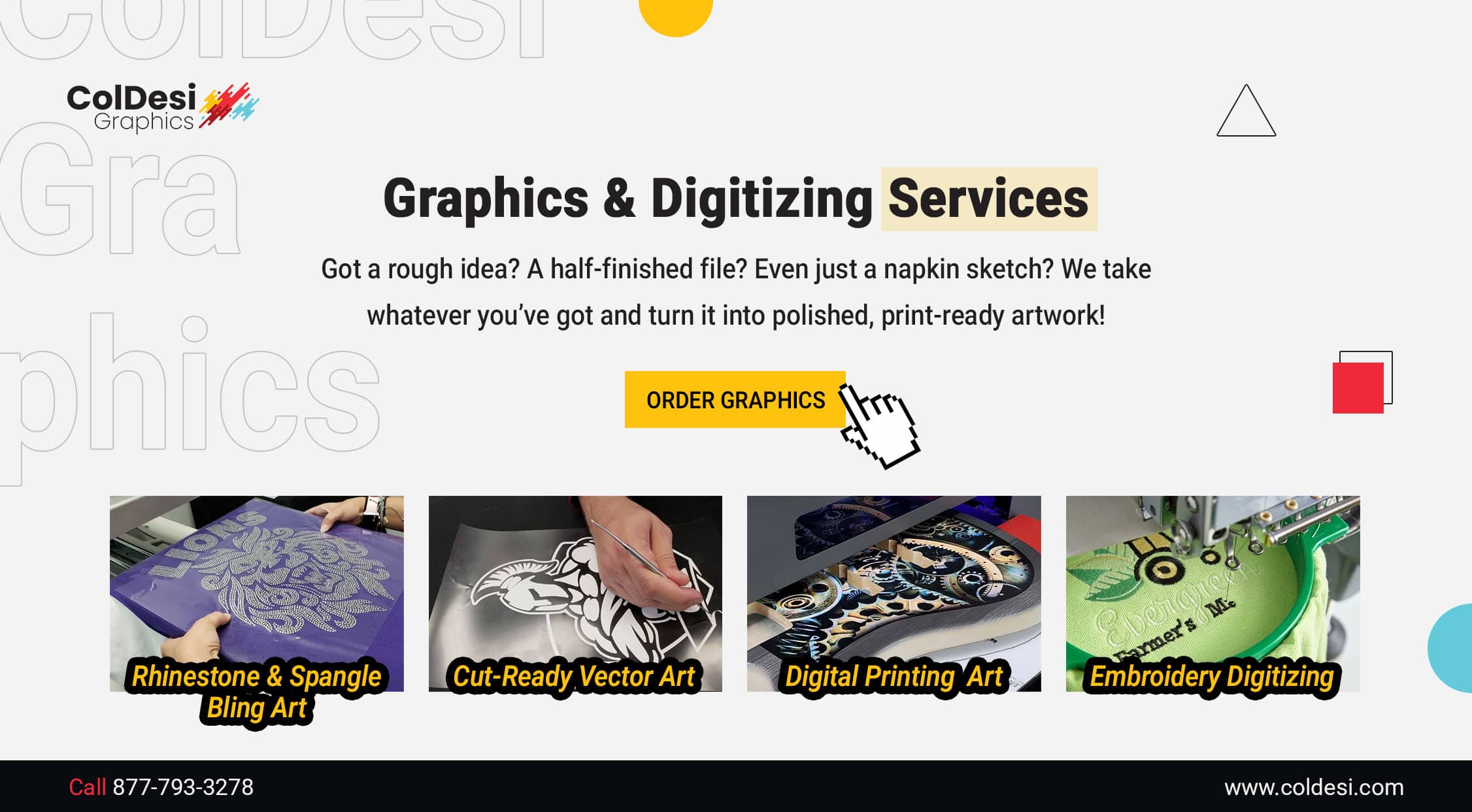

Whether it’s a logo, artwork, or custom idea, we turn your design into a high-quality embroidery file! Click here to learn more.

Introducing Avancé Line of Commercial Embroidery Machines from ColDesi.

If there’s one thing we’ve learned from all this, it’s this: it’s time for you to get a new embroidery machine.

Easier said than done, right?

You might be wondering, “Where do I even start looking for a high-production embroidery machine, and which make and model should I choose?”

Well, probably not at the place where you bought your current one. There are better options out there, and we want to show you two machines that could be exactly what you need.

Below, we’ll walk you through each machine, highlighting their key features and specs, explaining who each is best for, and outlining the differences between them.

Avancé 1201C – Let’s start with the Avancé 1201C. It’s a 12-needle commercial embroidery machine designed for small businesses, startups, and home-based studios that want commercial-level results without going fully industrial just yet. Compact, fast, and surprisingly capable, this model proves that big capabilities can come in small packages.

The 1201C can sew up to 1,000 stitches per minute, which is impressive for a machine its size. Measuring 23 x 23 x 63 inches and weighing about 176 pounds, it is actually the smallest and lightest Avancé model to date, but don’t let that fool you. It’s built to keep up with demand.

Up front, there’s a 10.1-inch full-color LCD touchscreen control panel that makes managing designs and settings simple. You’ll find 28 built-in fonts and a library of up to 4,000 designs, so you can start creating on day one!

And because Avancé likes to make life easy, the 1201C includes everything you need to get started — hoops, frames, thread, backings, and more. To top it all off, it comes at a more attractive price point than its bigger brother, the Avancé 1501C, which we’ll cover next.

Avancé 1501C – The Avance 1501C shares many features and components with the 1201C model. The control panel and user interface are identical, as is the onboard memory and library of fonts and designs it comes with.

It also includes the same training, support, and uses the same embroidery supplies.

The difference? It’s larger. In every sense of the word.

The physical size of the machine measures in at 33 x 30 x 63 inches. Some might take that as a drawback, but it’s an intentional design feature to accommodate a larger embroidery area and hoops that can fit the machine.

It was designed with power-users in mind, right down to the speed at which it operates (which caps out at 1,200 SPM). Combine all of that with 15 colors of thread on deck, and you have an embroidery machine that ticks all the boxes.

It’s worth mentioning that you can start with a single unit and, of course, expand by adding more machines as needed, creating a so-called modular embroidery setup by connecting multiple machines on the same network.

We also have an article you can read to learn more about this and get a deeper understanding.

Now that you’ve seen how these two machines compare in terms of features, specs, and ideal use cases, the choice should feel a lot clearer.

You’re probably already leaning one way, and rightly so, because the decision is ultimately up to you to make.

But, choosing between them isn’t about chasing specs just to say you have them. And it’s definitely not about buying the biggest, flashiest machine you can afford.

It’s about matching the right tool to the kind of work you’re doing now, and the kind of work you realistically plan to be paid for next.

In the next section, we’ll look at the productivity features these machines offer, such as automatic thread changes, larger embroidery fields, and other practical quality-of-life improvements that save time and make embroidery work smoother and less hands-on.

Discover how switching to a modular embroidery system can double your output and flexibility without increasing your labor costs. Read THIS.

Productivity Features of Avancé Commercial Embroidery Machines

We touched on a few productivity features earlier, but now it’s time to put them front and center. Because these are the ones that separate semi-professional embroidery machines from commercial-grade units.

Simply put, these features decide how much you get done in a day.

They cut downtime to almost nothing, speed up production, and help you finish more pieces in a single shift than most machines do in two.

Automatic Color/Thread Change – Both commercial Avancé models, namely the 1501C and 1201C, support automatic color change during embroidery runs. This lets the machine switch to the next needle thread in sequence as your design calls for different colors, eliminating the need to manually stop and re-thread between colors.

Large Embroidery Field – An embroidery field defines how large a design (or maximum stitchable area) you can embroider in one run. It is often called embroidery area or sewing field as well. To give you a good perspective, Avancé 1201C embroidery machine can cover 14″ x 7.8″ (200x360mm) without you stopping, re-hooping, or repositioning the garment. While Avancé 1501C gives you a generous 22″ x 14″ (560mm x 360mm) embroidery area for larger designs.

High Stitching Speed – Avancé machines, like the 1501C model, can reach speeds of up to 1,200 stitches per minute (SPM), allowing for faster project completion and higher output than many competitors.

Built-in Fonts & Designs – The machines include a strong selection of 28 built-in fonts and 4,000 embroidery designs to get you started from day one. Should you need more, you can transfer designs from a computer to the machine via USB.

Thread Break Detection – This is a safety and quality‑control feature built into both the 1501C and 1201C models. It uses sensors to monitor thread movement; if the thread stops moving because it broke or got snagged, the sensor detects this interruption and signals the machine to stop instantly.

Automatic Thread Trimming – As the name suggests, this is an automated mechanism in Avancé professional embroidery machines that cuts thread tails whenever a color change occurs, when the pantograph moves to a different location in the design, or wherever your digitized file calls for this function. Once these conditions are met, the mechanism is triggered

These Productivity features work together to deliver best-in-class throughput performance for Avancé embroidery machines.

Every single one on the list plays a part in keeping your production running smoothly and efficiently.

Of course, there are plenty more we haven’t touched on, but we’ll leave that little homework for you.

Right about now seems to be the perfect time to talk about how these embroidery machines pay for themselves.

Stop struggling with difficult garments! Learn how these supplies can make your embroidery faster, easier, and more profitable. Click here to learn more.

How Can You Make Money With an Embroidery Machine?

Nobody wakes up and says, ‘Hey, I think I’ll spend $10,000 on a commercial embroidery machine… just for the fun of it.’

You buy a machine like this for one reason only: to make money.

Not tomorrow. Not next month. Now.

Every single dollar you invest in it has to earn its way back… and then keep on working for you long after it’s paid off.

Luckily, that’s exactly what the Avancé embroidery machines from ColDesi are designed to do.

These machines are built to work as hard as you do.

But owning the machine is only half the equation. The real question is how do you use it? And how do you turn it into real money?

Given below are some ideas on how to do this.

Custom Apparel – One of the most immediate opportunities is custom apparel. Businesses always need branded clothing, be it embroidered hats, polos, hoodies, jackets, and workwear. Each piece takes just minutes to stitch, costs very little in materials, and can sell for a premium. Think beyond traditional businesses: gyms want staff uniforms, restaurants need embroidered aprons, construction crews need durable branded gear, schools want uniforms or team apparel, and delivery services rely on branded jackets, polos, or caps to present a professional image while out in the field.

Personalization & Custom Pieces – Another lucrative avenue is custom, one-of-a-kind pieces. Names on towels. Initials on bags. Monograms on baby blankets. Personalized gifts consistently outsell generic products because they feel special, and people are willing to pay extra for that feeling. And the good news is that these jobs are often quick to produce and they carry high perceived value. That means strong margins with relatively low production time.

Corporate & Contract Work – There’s also a huge opportunity in corporate and contract work. Many organizations, schools, sports teams, and event organizers prefer to outsource their embroidery rather than invest in their own equipment. If you consistently deliver high-quality, dependable results, you can become their go-to partner, securing repeat contracts that provide steady revenue. The key here is professionalism and reliability. Once you earn trust, large and recurring orders will follow.

Promotional Products & Merchandise – Don’t overlook promotional products and merchandise, either. Businesses constantly need branded items for marketing campaigns, events, and giveaways. Tote bags, hats, and apparel are in demand year-round, and companies are happy to pay a premium for items that help them get their name out. This type of work can keep your machines running year-round, especially during trade show seasons, corporate events, and back-to-school promotions.

Flexible Business Model – Finally, an embroidery machine gives you a flexible business model. You can sell wholesale to retailers, work with local clients directly, run an online store, or accept on-demand custom orders. This flexibility allows you to scale in multiple directions and ensures you’re never dependent on a single source of income.

These are just a few of the many ways an embroidery machine can generate income, and again, none of this is new.

These methods have been working for years. The opportunity is already there; the demand doesn’t need to be created, it already exists.

You just need to find those customers, give them what they want, and keep doing it.

Do that, and not only will the machine pay for itself many times over, but you will also build a sustainable, profitable business as a direct result of it.

Some food for thought today.