We get it. You’ve had enough. It’s time to upgrade to a multi-needle embroidery machine.

Not because you want something “new.”

Not because “everyone else is doing it.”

But because something about your current setup just isn’t working anymore. And it’s becoming impossible to ignore.

It’s frustrating. One of those problems that’s hard to explain unless you’re the one living with it every day.

But if we had to guess, we’d say this:

Your embroidery machine is slow, unpredictable, and just a little too loud.

And you? You’re left wishing projects finished faster, clients were bigger, and the process was actually… fun.

Funny, isn’t it, that you ever agreed to this relationship in the first place?

The good news? There’s a way forward. A way to make your work smoother, faster, and yes, actually enjoyable again.

The solution is the Avancé line of commercial multi-needle embroidery machines from ColDesi.

It’s a bit of a mouthful, but this is the upgrade you’ve needed all along.

- Projects finish on time instead of dragging on for days.

- Fewer thread breaks, fewer errors, less wasted material.

- Less noise and vibration.

Instead? You press a button, and the machine just works. Just the way you want it to.

As a result, you can take on bigger orders, keep your clients happy, and finally get some of your day back.

But the benefits go way beyond that.

So in this article, we’ll show you exactly what upgrading really buys you—measurable, practical benefits you’ll notice immediately.

We’ve got a lot to cover, so let’s get into it.

What is a Multi-Needle Embroidery Machine?

Let’s start with the basics: What is a multi-needle embroidery machine?

And how does it differentiate from other types of embroidery machines, like single-needle, home, hobby, semi-professional, or entry-level machines?

Here’s the simplest way to understand it.

A multi-needle embroidery machine is exactly what it sounds like… an embroidery machine with more than one needle.

But that simple difference changes everything.

Instead of stopping every few minutes to rethread a new color, like you must do with single-needle machines, a multi-needle machine switches colors automatically.

Each needle is pre-threaded with a different color, and the machine automatically selects the correct needle as the design runs.

Depending on the make and model, a system can hold multiple thread colors at once (6, 10, 12, or even 15 needles).

And that’s an oversimplified explanation of what multi-needle embroidery machines are.

Of course, they’re much more than that.

But what are the main differentiators of these machines? What really sets them apart?

Speed and Throughput – Multi-needle machines are built for repeat work. While single-needle or hobby machines are designed to run one item (and one color) at a time, multi-needle machines are designed to run for hours at a time, day after day.

What might take 45–60 minutes on a single-needle machine can often be completed in a fraction of that time on a multi-needle system.

Most multi-needle machines also run at significantly higher stitch speeds, often ranging from 800 to 1,200 stitches per minute (or more), while maintaining consistent stitch quality. The result is higher output per hour, per day, and per operator.

Commercial-Grade Components – Multi-needle machines aren’t just faster; they’re built differently. These machines are designed for real production, not occasional use. Heavier frames, stronger motors, and more durable internal parts that can handle long hours of use.

Over time, this reliability translates into fewer slowdowns, fewer repairs, and less stress when you’re trying to get work out the door.

Modularity – You can start with a single machine and expand by adding more units as your business grows, creating a so-called modular embroidery setup. You can cluster 2, 3, 6 or more units on the same network.

This arrangement allows you to control every machine on the network from a single computer and manage individual machines as needed, without interrupting production across the entire network.

Additionally, this centralized control lets you manage each embroidery machine individually and assign jobs to each machine in the network as you see fit.

For those who want more, we’ve got another article that goes deeper into the differences between single-needle and Avancé multi-needle embroidery machines, as well as their features and specs. Click here to learn more.

What Makes for Quality Embroidery?

Did you read the article we linked above?

If not, we strongly recommend that you do so. Because it not only explains what separates a hobby machine from a commercial one, but it also helps you decide which model to purchase, along with the essential supplies for it.

Now…

Assuming you’ve read that, let’s move on to the next, and arguably more important, question:

What makes for quality embroidery?

And to answer that, we must first understand that quality embroidery is not defined by a single factor, but by how several elements work together.

So, let’s take a look at them individually.

Design Selection – It all starts here. Not every design works on every fabric, size, or project. Too much detail, too much density, or the wrong scale can mess things up in ways no machine setting can fix. Before you touch the machine, ask yourself one simple question: Is this design actually going to work for what it’s meant for? Because everything that comes after depends on getting this right.

Fabric & Thread Choice – Once you’ve picked (and digitized) the right design, the next step is to choose the right fabric and thread. It sounds simple, but it makes a huge difference in the final result. Not all fabrics behave the same under a needle, and not all threads hold up equally. Choose the wrong combination, and even a perfect design can end up puckered, distorted, or fraying.

Stabilization – The next thing to think about is support. Embroidery is basically punching thousands of tiny holes into your fabric, and without proper backing, your material can shift, stretch, or bunch up. To keep it under control while stitching, you need a stabilizer, sometimes called backing. Tear-away, cut-away, and water-soluble stabilizers each have their place, depending on the fabric, stitch density, and how the finished piece will be used.

Hooping – Last but not least, how you hoop your fabric matters more than most people realize. If the fabric isn’t hooped correctly, everything else we’ve talked about can fall apart. Your fabric should sit flat, smooth and secure in the hoop, but not stretched. Too loose, and it can shift while stitching. Too tight, and the design can warp once it’s removed

And that’s really the point to understand here.

When you step back, that’s really what quality embroidery comes down to.

While this isn’t an exhaustive list, we offer it as a start.

Get those fundamentals right, and quality follows naturally.

Let’s move on and put Avancé embroidery machines head-to-head with other leading commercial brands.

Avancé vs Every Other Embroidery Machine

By now, you’ve likely done your research, narrowed your choices to a few ideal embroidery machines, and settled on a single brand (ahem, Avancé).

Still, you may have questions or concerns about whether it’s the right choice and how it compares to other leading commercial brands.

Well then, let’s dedicate this segment to addressing those concerns by taking a closer look at warranty coverage, customer support, onboarding, training, and overall value of Avancé multi-needle embroidery machines.

- 5-Year Warranty: Here at ColDesi, we proudly offer a five-year warranty on our Avancé line of commercial embroidery machines, giving you long-term peace of mind with your investment. For those who want more than that, there are options to extend it. If any component fails within that warranty period, we'll work with you to make things right. Whether it’s a replacement, a return, or another solution!

- Nationwide After-Sales Support: Something went wrong? No problem. One call or email connects you to real people who know these machines inside and out. Nationwide support means no matter where you are, help is always within reach. So, in case of an unwanted accident, an unknown error, or a breakdown of the embroidery machine, our experts are ready to step in and get you back up and running. Knock on wood, you’ll hopefully never have to use it.

- Simplified Training & Onboarding: We can’t forget to mention that Avancé embroidery machines come with the best training and technical support in the industry. Our free resources include how-to guides, detailed documentation, video demonstrations, tutorials, even informative audio podcasts you can listen to while you work. We teach not only the basics of embroidery but also the advanced capabilities of your new equipment.

- Reputation and Reviews: Over the years, we’ve earned consistent positive feedback for both our company and our product lineup. We’ve been praised for our strong client relationships, problem-solving abilities, willingness to lend a helping hand, and our commitment to going above and beyond to ensure our clients are happy. Above all, we take pride in doing honest, reliable work.

Taken together, these factors make ColDesi a clear, low-risk choice.

As you can see, it is not just about the machine itself.

The warranties, real-world reviews, and the training and support you get afterward all shape your daily experience.

They show what ownership will actually feel like and make sure you are not left figuring things out on your own.

By looking at the whole picture, not just the specs, you can make a confident choice that will continue to feel right over time.

Machine Embroidery Products & Supplies

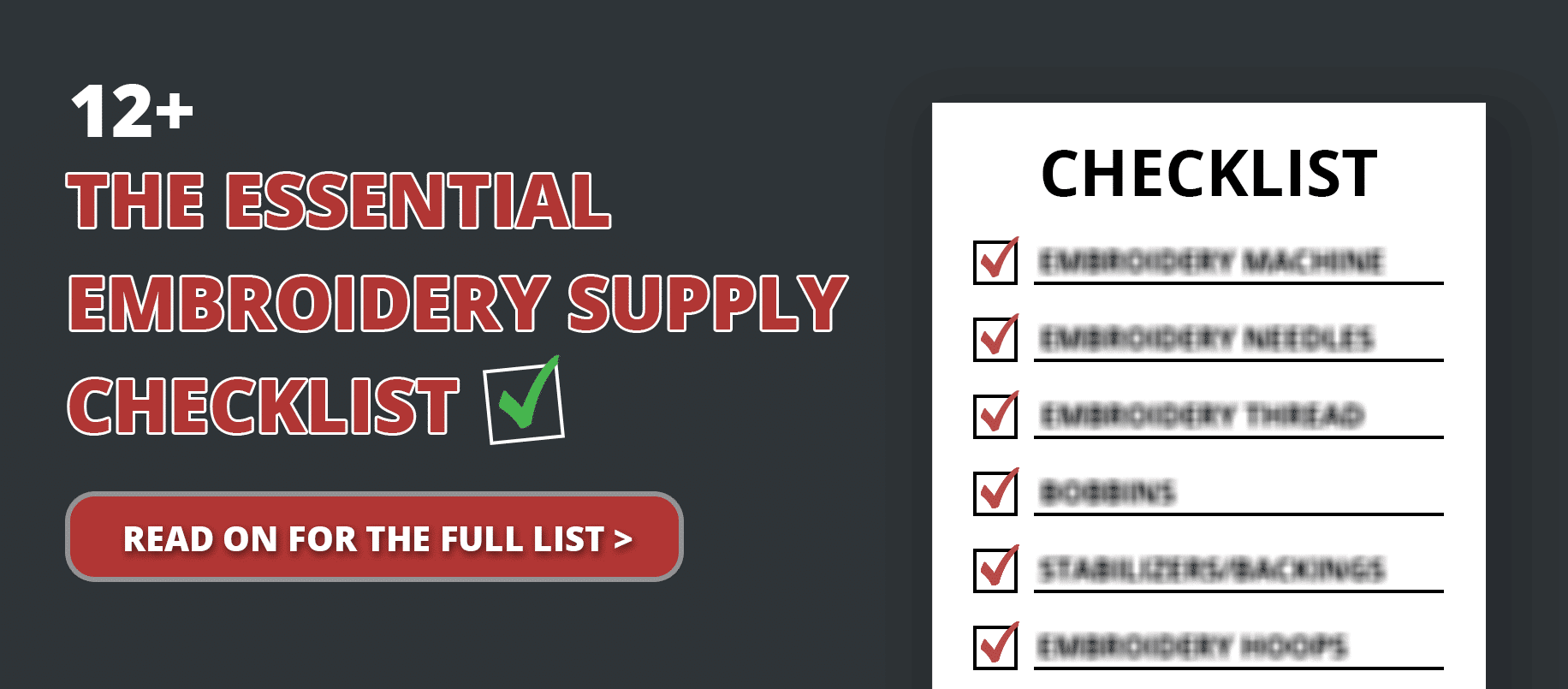

To round this out, let’s look at some of the essential machine embroidery supplies, tools, and accessories you’ll want to have on hand when working on embroidery projects.

Whether you’re just getting started or refining your process, having the right supplies makes the work smoother, faster, and far more consistent.

To help with that, we’ve put together a comprehensive article that covers each product in clear, practical detail.

You can read it below.

Stop struggling with difficult garments! Learn how these supplies can make your embroidery faster, easier, and more profitable. Read THIS.

Think you have all the embroidery essentials? Complete your kit with these hand-picked must-haves. Click here to learn more.