Custom patch making keeps rising in popularity and being able to produce digitally printed patches is an easy way to stand out from the competition.

Short run or one-of-a-kind embroidered patches are a great business. They’re good for lots of different applications and a wide variety of niche markets.

Like motorcycle clubs, uniforms, backpacks and gear for schools and more.

But photos of cars, boats, pets and family just don’t embroider well. THAT’s where sublimation comes in! It’s a great way to produce high quality photos for pressing onto fabric and promotional products… And it turns out, patches too!

So, we are going to walk you through the steps to make your own printed patches and the equipment needed.

Equipment Used |

Avance 1501C Embroidery Machine & Sawgrass Sublimation Printer

Ready to start a customization business? The biggest question people ask themselves is, “What machine is right for me?”

Well, both the Avance embroidery machines and sawgrass printers are popular options for our customers who are just starting out.

By themselves, they can be huge money makers in the customization business. Together, these machines can put you in a unique position to put your business on top right out of the gate.

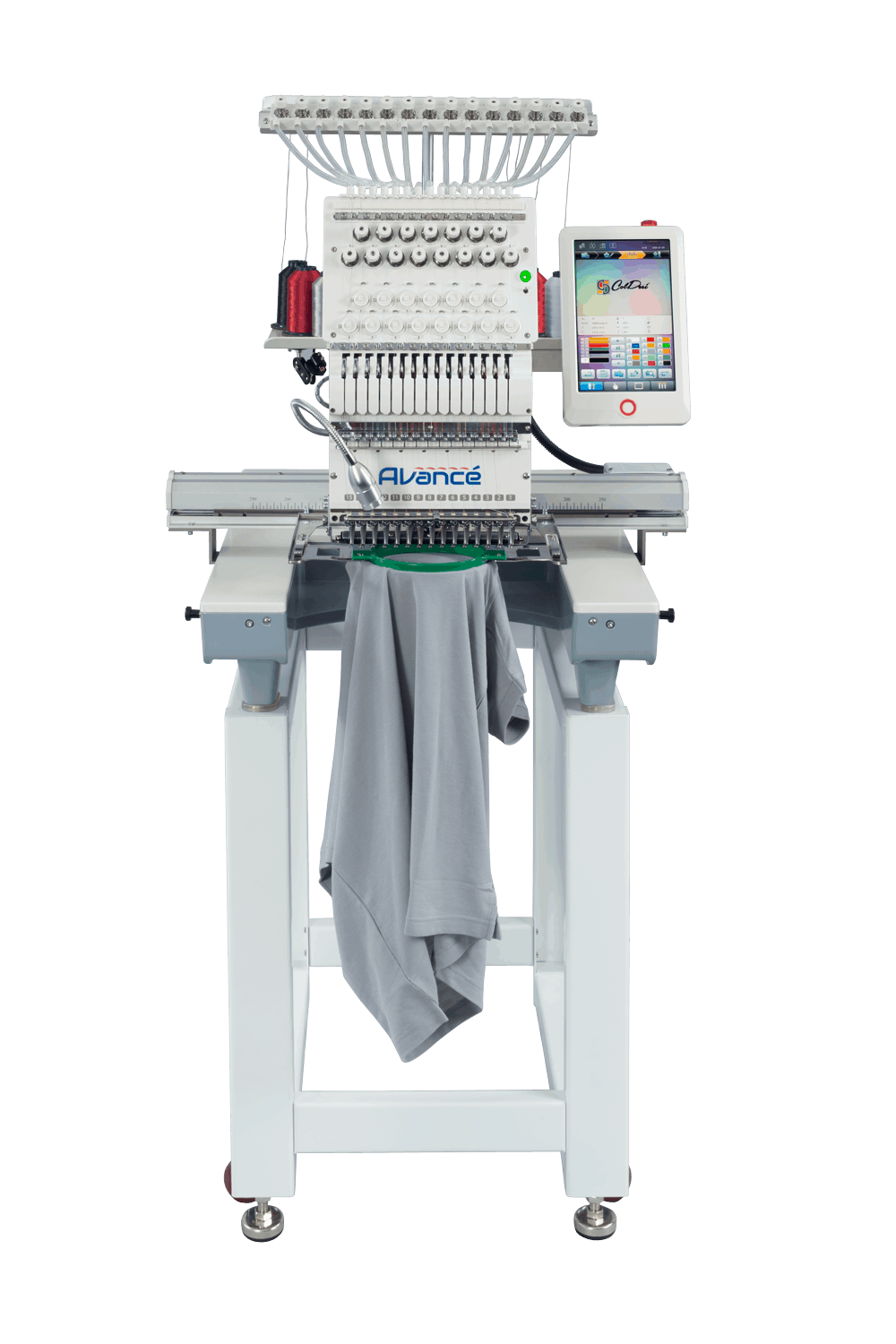

Avance 1501C 2020 Embroidery Machine

The Avance 1501C 2020 is a commercial embroidery machine that is great for big businesses that are serious about embroidery but is also the perfect fit for home-based businesses and hobbyists.

It features a touch-screen control panel that lets users easily navigate a digitized file from import to sew out.

This machine comes to your door with everything you need to start embroidering everything from company polos to custom caps and gift items. And that HUGE embroidery field makes it perfect for larger projects like jacket backs, blankets and table runners.

Embroidery businesses usually have a specialty, like company uniforms, left chest logos, monograms, or school spirit wear. And a machine like the Avance single head, 15 needle embroidery machine is ideal for just those niches.

But when customers are looking for family reunion tees, event shirts and promo products, embroidery businesses loose out.

Sawgrass SG1000 Sublimation Printer

Sawgrass Sublimation printers offer a very affordable way to start a custom tee business. Sublimation creates very vibrant full color digital prints.

These prints can only be transferred to white or light-colored polyester. So, poly tees are a very popular sublimation blank but so are polyester coated promotional goods like mugs, coasters and license plates.

The biggest limitation of sublimation is not being able to decorate dark garments or cotton.

Together these two machines fill in each other’s blanks. But they also give you the opportunity to create some super unique customization items, like printed patches.

How To Make Printed Patches

ColDesi’s supply division, Colman and Company offers both embroidery and sublimation supplies and blanks. One of the most popular embroidery materials sold on the site are patch making materials.

The patch kit on Colman and Company has everything that embroidered need to start making custom patches, including both Patch Twill and Patch Mat.

These two materials are the base for making a patch and the best part is they are 100% polyester. This means they are sublimate-able!

Steps to making sublimated patches:

1. Print out your digital photo on the Sawgrass SG1000 on a special piece of sublimation paper. We used an 8.5” X 11” sized sheet of the Beaver TexPrint paper. Because custom patches are usually small, we were able to print tons of different photos on one sheet of the paper.

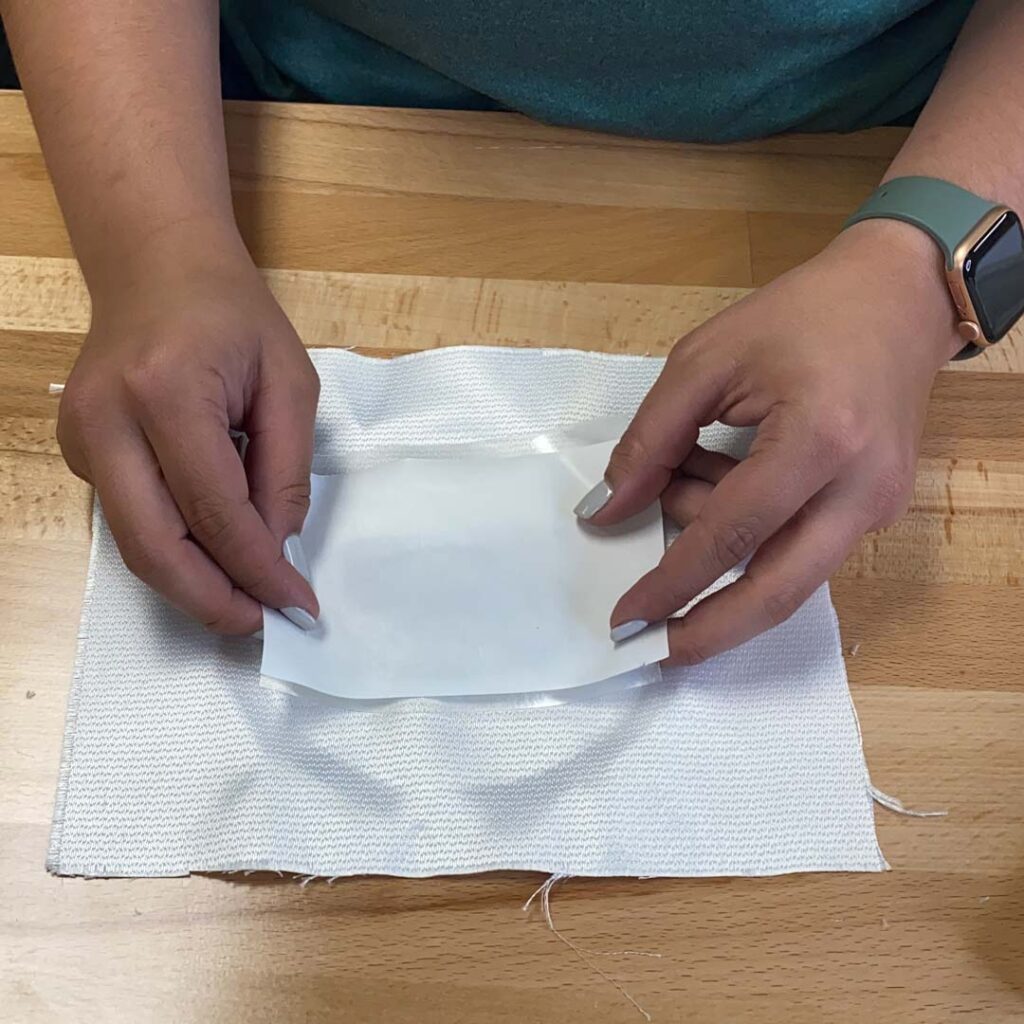

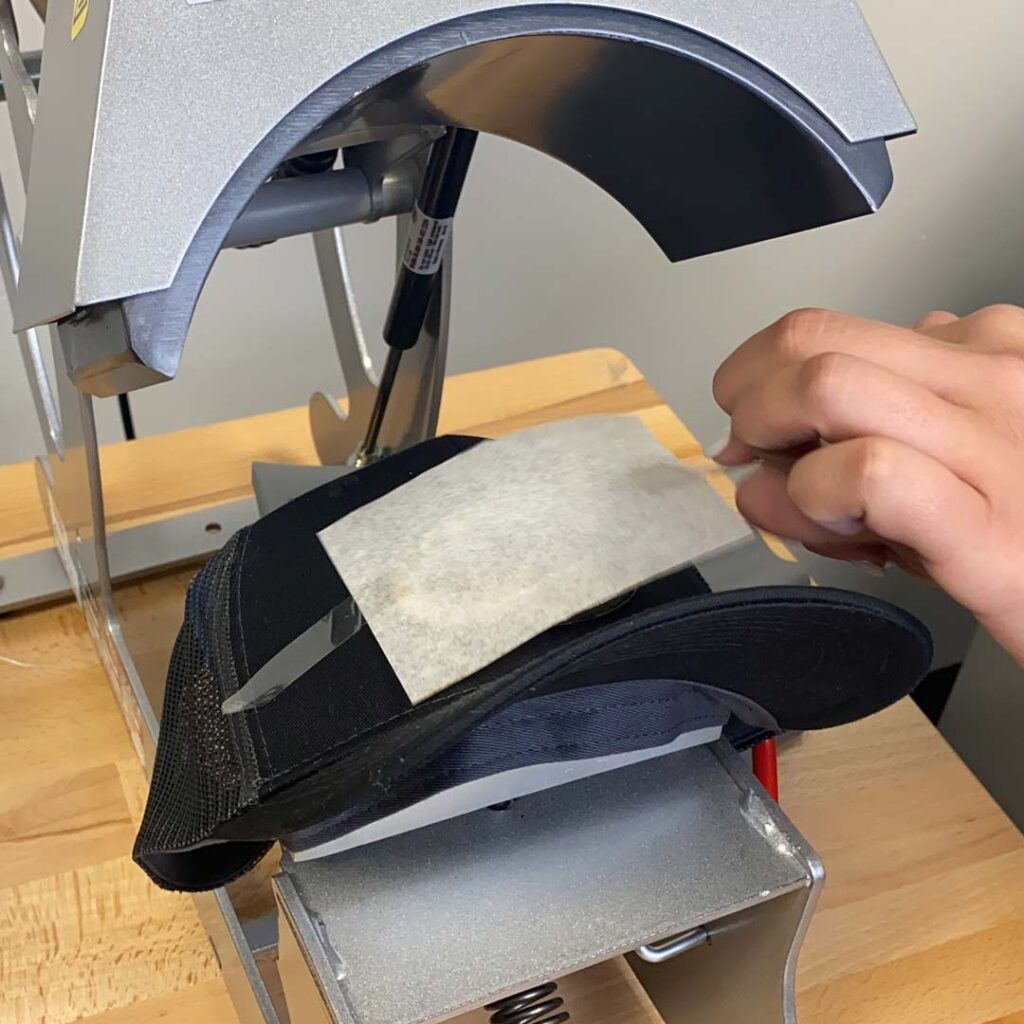

2. Heat press your photo onto a piece of white patch material, then carefully remove the transfer paper.

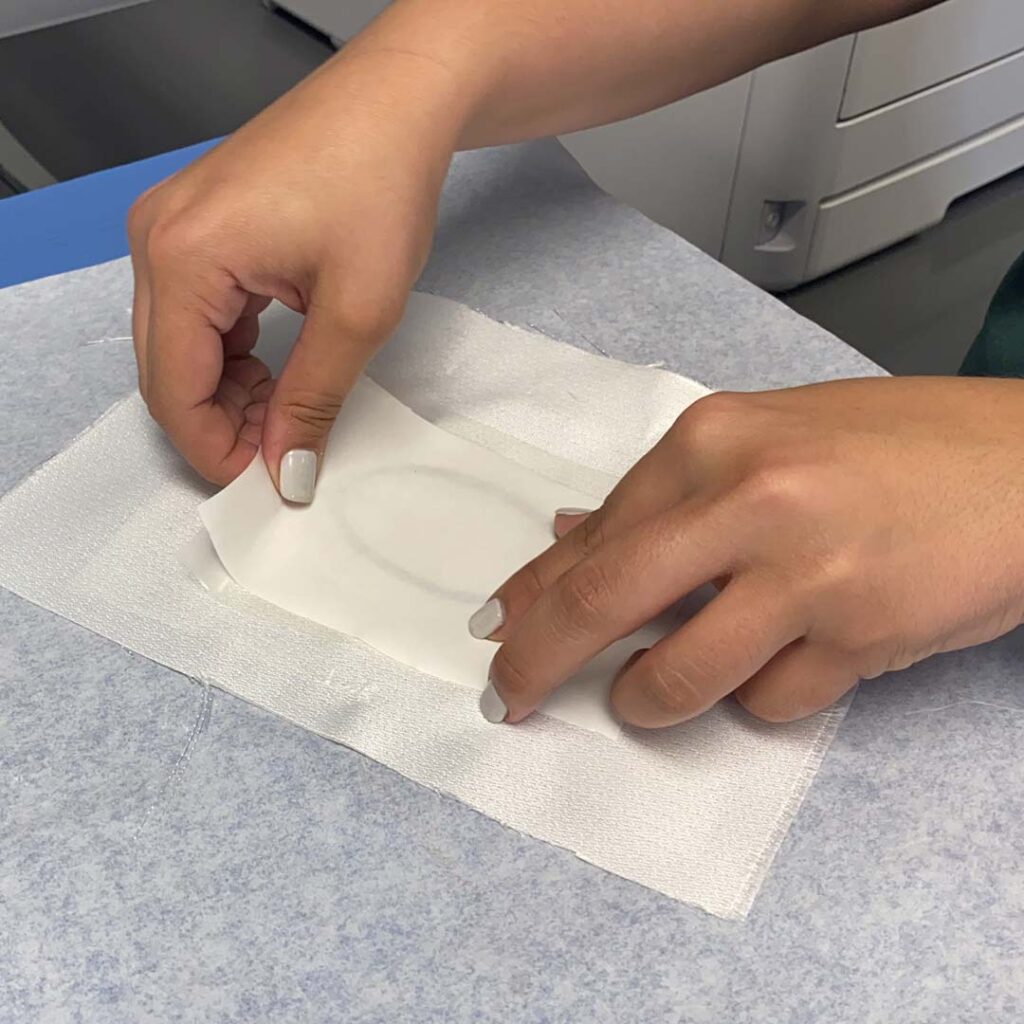

3. Next you will heat press a piece of Heat Spun to the back of the patch material. The Heat Spun is like webbed glued and once it’s applied to the back of the patch, it will give it more stability and secure the patch mat fibers together.

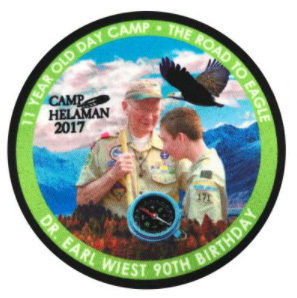

4. Now you will hoop the patch and put it on your embroidery machine. We ordered a thick oval patch border from ColDesi Graphics for this project.

5. Then you will add Heat Seal to the back of the embroidered patch. The Heat Seal is going to give your patch a nice firm feeling and is also going to give you the ability to heat apply your custom patch onto anything.

6. Next you will use the hot knife to cut your patch out and seal the edges at the same time.

7. So, this patch is now ready to go and be sold as is. But, for this project we are also going to heat apply this patch to a hat. We are using our Hotronix Cap Press for this and once we get the hat secured on the platen, we will place the patch in the center.

8. Next you will use heat tape to keep the patch in position, then lay finishing paper and the flexible finishing sheet on top. (The flexible finishing sheet is going to help reduce creases on the hat that can sometimes happen when heat pressing.)

9. Now you have a custom hat featuring a digitally printed patch!

Other Customization Ideas:

More customization equals more retail value. So, any extra little feature that you can add to decorated patches can put more money in your pocket.

Here are some ideas for custom patches you could offer customers:

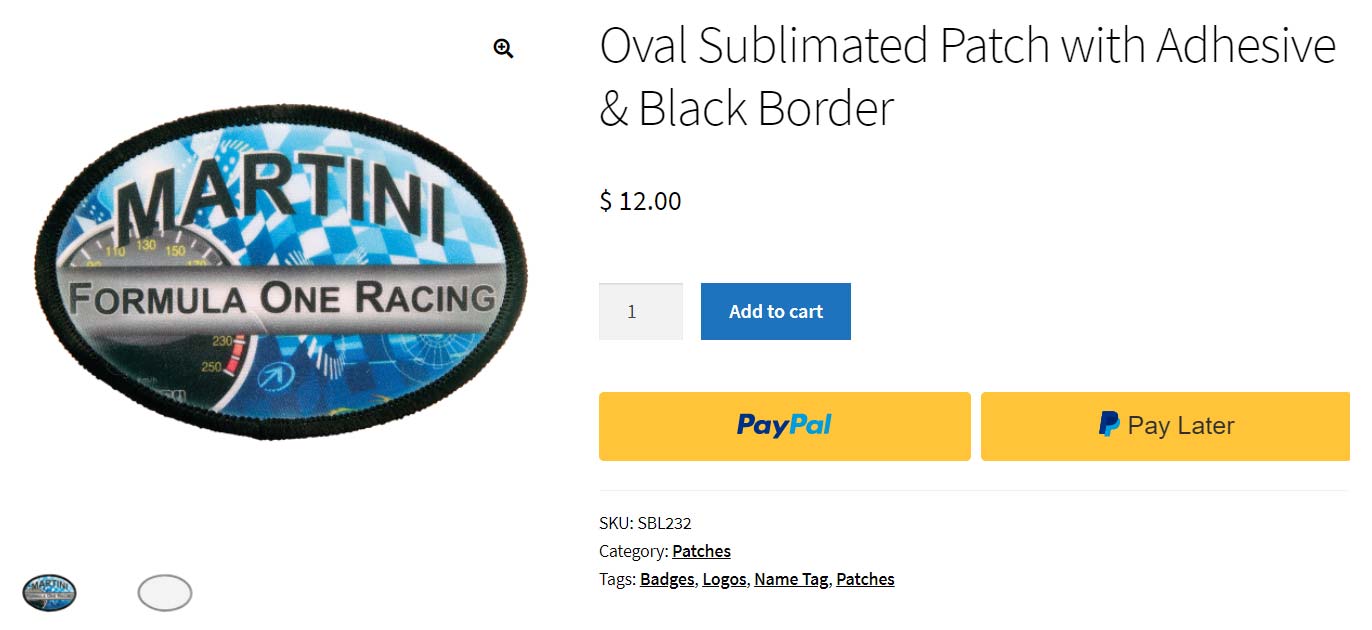

- Car photo with race team name

- Boat photo with boat name

- Show car with Instagram handle

- Scout achievement patches with troop numbers

- Aviation patches with division name

- State patches with digital symbols

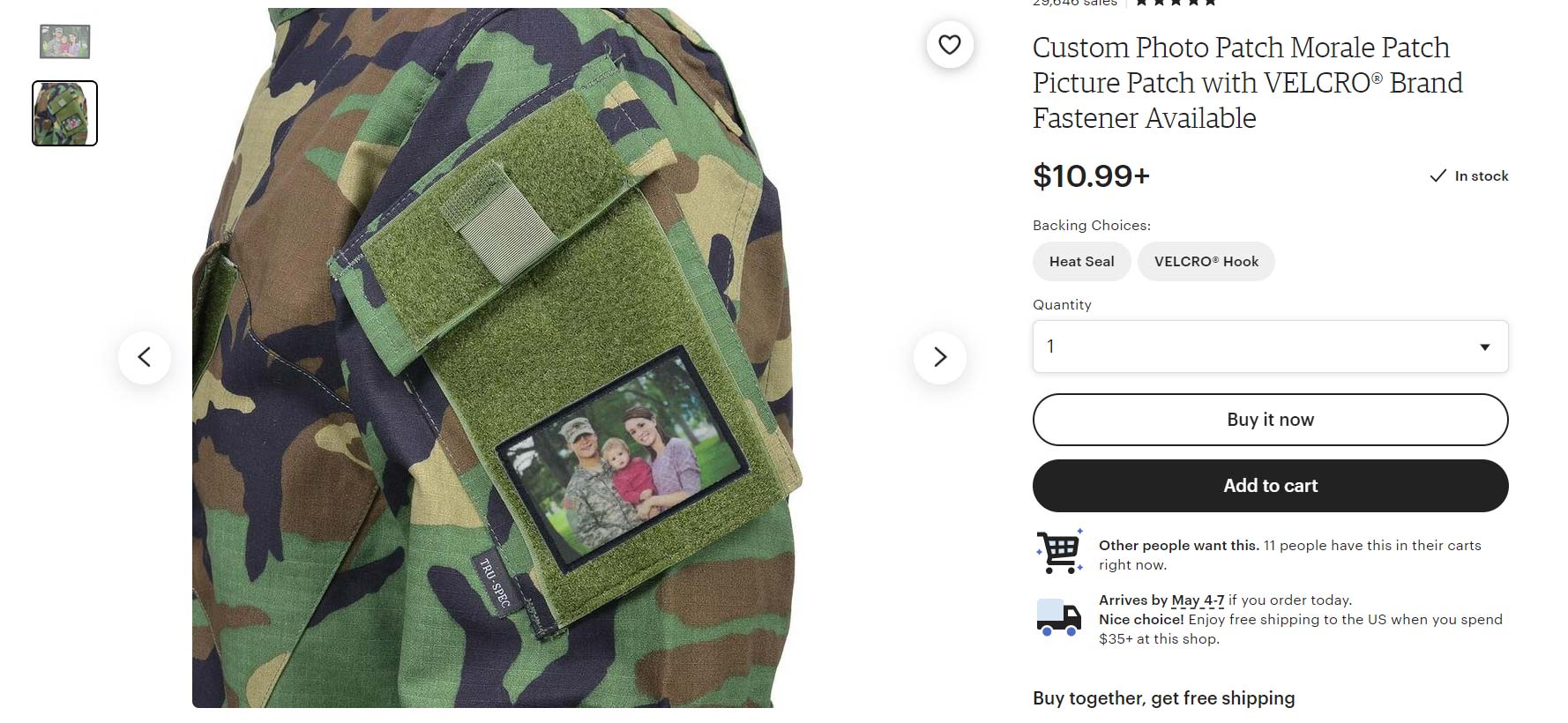

- Family Portraits

- Unique Military Uniform Patch

Getting Started

This is also a great time to ask about special deals like 0% financing. Leasing apparel decorating equipment, like embroidery machines, is a great option because cash flow is so important when you’re first starting out.

You can live chat with the pros at ColDesi.com or call us at 877-793-3278.