How to Charge for Embroidery

Understanding the Basics of Pricing Embroidery

- Per Stitch: This is the most common method of pricing embroidery. You charge clients according to the number of stitches involved in their design—the more stitches, the higher the price. This method is ideal for designs that are complex or intricate.

- Per Design: For simple designs, you may opt to charge a flat rate, regardless of the number of stitches. This pricing method can be easier for clients to understand. It’s essential to ensure that the design cost accounts for your time and resources.

- Per Garment: If you are working on a large order with multiple garments, charging per item can be a straightforward approach. This method allows you to account for both the garment and the embroidery.

Your business may benefit from a combination of these pricing structures, depending on the specifics of each job. It is essential to be adaptable depending on the project. Consider other factors, in addition to stitch count and garment type, when determining rates.

Core Pricing Models

Per Thousand Stitches

A common method is charging per 1,000 stitches. For example, a 10,000-stitch design priced at $1.25 per 1,000 stitches would cost $12.50. Adjust this baseline yearly to reflect higher thread, stabilizer, and labor costs.

Per Item

Flat-rate pricing works for caps, polos, or jackets with standard designs. This is simple for customers but requires careful cost tracking.

Setup and Digitizing Fees

Charge a one-time fee for new designs. Digitizing software and AI platforms streamline this, but setup still requires time and expertise.

Dynamic Pricing

Static pricing doesn’t reflect today’s realities. Instead, embroidery businesses should adopt dynamic pricing models:

Material Adjustments: Update pricing quarterly to account for rising costs of thread, stabilizer, and blanks.

Labor Adjustments: Factor in higher wages and benefits when calculating per-piece costs.

Rush Orders: Add surcharges for jobs needed within 24–48 hours.

Bulk Discounts: Offer tiered pricing for large orders to stay competitive.

Key Factors That Affect Pricing in Today’s Economy

Design Complexity

Customers expect high-quality, detailed designs. The complexity of the embroidery plays a significant role in pricing. Multicolored, intricate patterns take more time and resources to complete. Charge more for these projects to ensure you are compensated for the extra effort involved.

Garment Type

Embroidery is not a one-size-fits-all service. Garments vary in fabric type, thickness, and quality. Each type requires different techniques, machine settings, and thread choices. Embroidering on a lightweight t-shirt differs from embroidering on a jacket or a cap. Take into account the garment’s specific needs when determining how much to charge.

Thread Count and Color

In the embroidery business, the more colors or threads you use, the higher the cost. While you may not charge extra for a straightforward design with minimal color, more detailed designs or those requiring specialty threads—such as metallic or high-contrast colors—will drive up the price. Be sure to communicate this to your clients upfront.

Quantity

Because of e-commerce and bulk ordering, many businesses receive large orders from companies looking to embroider logos or names on assorted items. Larger orders allow for discounts. The per-item cost should still reflect your base rates for stitching and overhead. Be sure to account for potential savings, but ensure that the volume doesn’t erode your margins.

Customization and Special Requests

As personalization becomes more sought after, customers may request specific customizations, such as adding a name, date, or unique design element. While customization adds value for your customers, it also requires extra labor. This should be factored into your pricing. Do not forget to set clear pricing guidelines for custom embroidery to prevent surprises.

How to Calculate the Cost of Embroidery

- Material Costs: This includes thread, stabilizers, needles, and other consumables.

- Machine Time: Your embroidery machine operates on a per-stitch basis, and you should know how much time it takes to complete a design.

- Labor Costs: Factor in the time it takes for you or your team to set up the machine, hoop garments, adjust settings, and complete the final inspection.

- Overhead: Don’t forget about rent, utilities, insurance, and other fixed costs associated with running your business.

You can use specialized software tools to help estimate embroidery costs. Alternatively, you can calculate a rough estimate using a cost-per-stitch formula. Once you have your baseline costs, factor in the desired profit margin, ensuring that you’re pricing to both cover expenses and generate a sustainable income.

The Impact of Fast Fashion and the Need for Commercialization in Embroidery

The Shift to Mass Production

Fast fashion thrives on speed, volume, and cost-efficiency. Brands and retailers need to get new designs to market quickly, often within a matter of weeks, and at an affordable price point. This creates a high demand for efficient, mass-production capabilities. For embroidery businesses, this means shifting from small-batch, custom work to larger, automated runs to meet the volume and turnaround times required by fashion companies and retailers.

To capitalize on this shift, embroidery businesses must embrace commercial-grade technology. Manual or small-scale machines, while sufficient for smaller orders and intricate custom designs, simply cannot meet the demands of large-scale production.

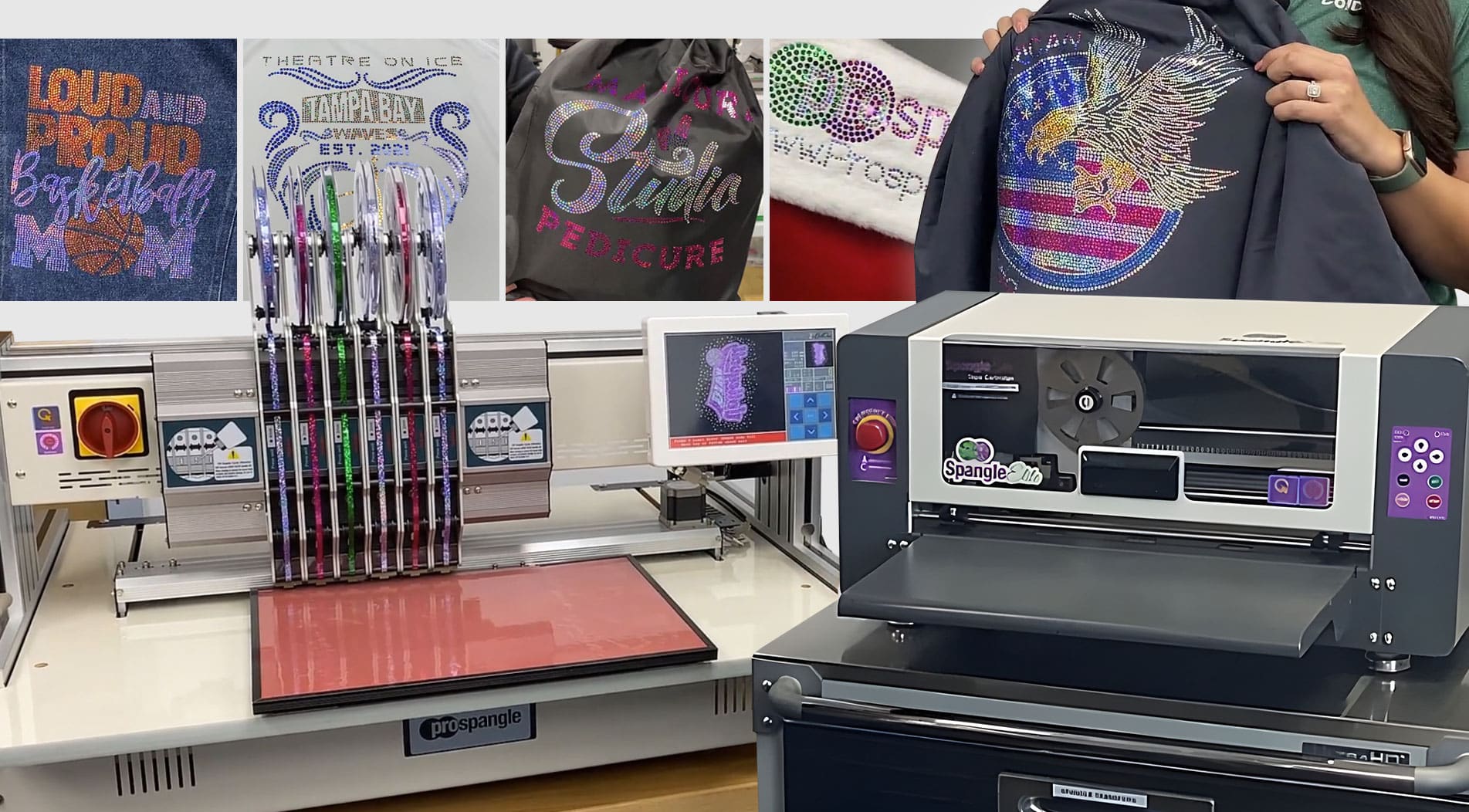

Incorporating a Commercial Embroidery Machine

Commercial embroidery machines are essential for meeting high-volume production demands. These machines manage large orders, produce designs quickly, and maintain consistent quality. They can embroider many garments at once, run for extended hours, and require minimal maintenance, making them ideal for mass production.

Advanced features like multi-needle capability, automatic color changes, and faster stitch speeds enable quick turnarounds without compromising quality. Their precision and durability ensure detailed, high-quality embroidery at scale.

Investing in commercial-grade equipment streamlines operations while reducing production times and controlling costs, all while upholding craftsmanship. This efficiency boosts profitability, expands client reach, and opens doors to large contracts.

Using Machine Performance to Price Smart

Modern machines change cost structures.

Avancé 1501C: Runs up to 1,200 stitches per minute. A 10,000-stitch design takes ~8–9 minutes, lowering labor costs per piece.

HappyJapan HCU2 Series: Speeds up to 1,500 SPM allow faster turnaround, which increases profitability on bulk orders.

By linking pricing to machine efficiency, you protect profits and stay competitive.

Adapting to Trends

Businesses must adapt by embracing commercial-grade equipment. Large-scale production for branded merchandise and promotional items requires high-capacity machines to meet demand.

Investing in commercial embroidery machines boosts output and expands market reach. It positions businesses as key players in mass-produced, high-quality embroidery. It’s not just about surviving in fast fashion, but also about thriving and seizing new growth opportunities.

Navigating the Changing Industry

The embroidery business faces challenges from rising costs, inflation, and shifting consumer trends. Staying profitable means regularly reviewing and adjusting your pricing.

Technology, such as digital software and automated machines, has sped up production and lowered some costs, but it also requires keeping up with fast-changing design trends and customer preferences.

To stay competitive, offer flexible pricing and clear cost breakdowns for custom work. With online platforms making price comparisons easy, ensure your rates match industry standards while highlighting your quality and service.

Avoiding Common Pricing Mistakes

A common mistake in embroidery businesses is underpricing. Lower rates may attract customers, but they often lead to burnout, thin margins, and poor sustainability. It’s essential to balance affordability with profitability.

Overpricing can also hurt your business. Charging more than competitors without added value may drive clients away. To avoid these pitfalls, research your market and update your pricing, ensuring your rates reflect your quality, material costs, and local competition.

Charging for embroidery starts with understanding cost factors and industry standards. Focus on design complexity, garment type, order size, and custom features. Build a pricing strategy that balances profitability with client expectations. Review your rates to keep up with costs and support long-term business success.

Get Expert Guidance on Pricing Your Embroidery Services

Contact ColDesi today to learn more about our embroidery solutions and how we can help your business thrive. Visit our website, live chat with a Pro, or call 877-793-3278. Let’s take your embroidery business to the next level!