Embroidery, the art of forming decorative designs with hand or machine needlework, has been around nearly as long as clothing itself. Evidence shows that Ancient Egyptians, Babylonians, Phoenicians and Hebrews used embroidery for decorating their robes. The Moors also decorated much of their clothing with embroidery. They had a style of their own which spread to other countries like Spain and Sicily. Moorish embroidery greatly influenced many European countries. The oldest embroidery works still in existence date back to the Middle Ages when embroidery was often used in ecclesiastical vestments as well as clothing. It also represented a sign of wealth, and rich traders and merchants were willing to pay a large sum of money for the luxury of embroidered clothing. A great example from this period is the Bayeux Tapestry, which is 231 feet long and recounts the Battle of Hastings in 1066

Jacob Schiess started the first commercial embroidery manufacturing establishment in 1848 in New York. He came from Switzerland and within a year had his own embroidery plant in operation. All the stitching was done by hand by fifteen woman stitching exquisite designs by hand.

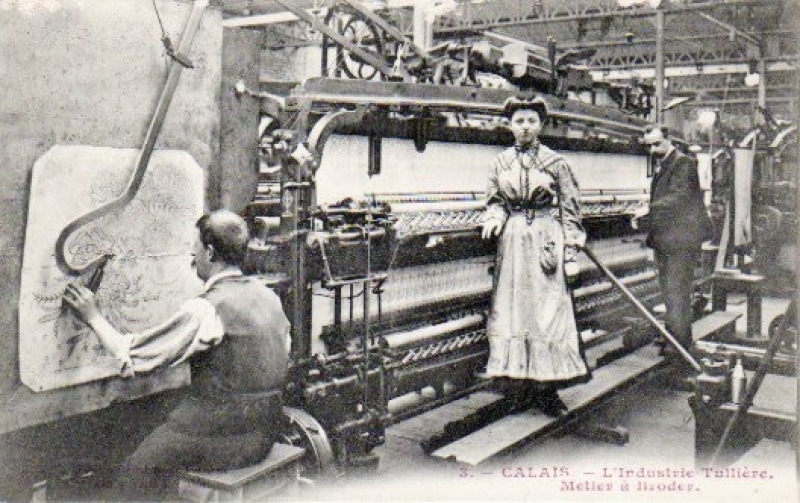

The development of machine embroidery did not take place until the 1800’s. Joshua Heilmann from Mulhouse worked on the design of a hand embroidery machine. Though he did not sell many, it revolutionized the embroidery industry. Heilmann’s invention was quickly followed by the “shuttle embroidery” and the “chain stitch embroidery” methods.

The beginnings of shuttle embroidery dates back to the 1860’s when Isaak Ggrlobli, from St. Gallen, Switzerland, was inspired by the work The oldest embroidery works still in existence produced on the sewing machine.

Around the 1870’s there were fourteen companies manufacturing embroidery machines in Switzerland manufacturing hand loom embroidery machines. Today there are four companies manufacturing schiffli embroidery machines.

In 1873, Alphonse Kursheedt imported twelve of the then new embroidery hand looms from St. Gallen, making him the first American to use a mechanized embroidery process. The looms used multiple needles and were an unbelievable improvement over the age-old process of stitching by hand. They were, however, powered manually.

Immediately afterwards, Issac Groebli of Switzerland invented the first practical Schiffli Embroidery machine. This machine was based on the principals introduced by the newly invented sewing machine. Groebli’s machine utilized the combination of a continuously threaded needle and shuttle containing a bobbin of thread. The shuttle itself looked similar to the hull of a sailboat. “Schiffli” means “little boat” in the Swiss dialect of the German language, so his machine came to be known as a schiffli machine.

In 1876, Kursheedt began importing a number of schiffli machines to America, thereby making him the real founder of the schiffli embroidery industry in the United States.

Dr. Robert Reiner, founder of Robert Reiner, Inc., of Weehawken, came to the United States in 1903 in his early twenties. Realizing the potential of the embroidery industry, he persuaded the Vogtlandishe Machine Works of Plauen, Germany, to appoint him it’s American agent. This began a mass importation of embroidery machines into northern New Jersey’s Hudson County. The banks arranged long-term credit to purchasers. Dr. Reiner made it possible for hundreds of Austrian, German, and Swiss immigrants in New Jersey to become manufacturers of embroidery.

The industry grew until 1938, when suddenly the two sources for the manufacture of machines in Plauen, Germany, and Arbon, Switzerland, ceased operation because of World War 2. No additional machines were produced until 1953, when Robert Reiner Inc. introduced the first American-made schiffli machine. Gradually in time, improvements were made to the machine in America as well as in Switzerland and Germany. Today computers are playing a major role in the embroidery process.

For more information about the history and cultural variations of embroidery, visit Wikipedia’s entry on the subject.

How ColDesi can help you get started?

We have focused our efforts on helping people like you take the first step into the profitable world of Apparel Decorating. The key components of our company are:

Best Deals

We offer several full package deals that include equipment, software, training and supplies which meet the needs of start-up embroidery businesses. Our Embroidery machine and Garment Printer Combo deal you can have a complete business that gives you unlimited possibilities and the flexibility to go after any niche, club, group, industry or product line you desire.

Best Value

When you compare ColDesi equipment to other premium brands of equipment, we want you to feel how committed we are to your success, how our support is second to none and how our innovation and production speeds are the best in the industry. However, when making an investment of this size you also want to be confident that it holds its value. Our Trade up Guarantee gives your business more flexibility for growth as you gain more sales and customers than any of our competitors – The 90% Embroidery Machine Trade up Guarantee and the 80% Direct to Garment Printer Trade up Guarantee.

ColDesi Embroidery Machine Industry Exclusives

Avancé embroidery machines are networkable and come with a 100% trade up guarantee. It is easy to expand and grow your start up embroidery business with Avancé embroidery machines. And if you are interested in embroidering caps, that ability comes standard with every single head or multi head machine we sell.

Training and Support

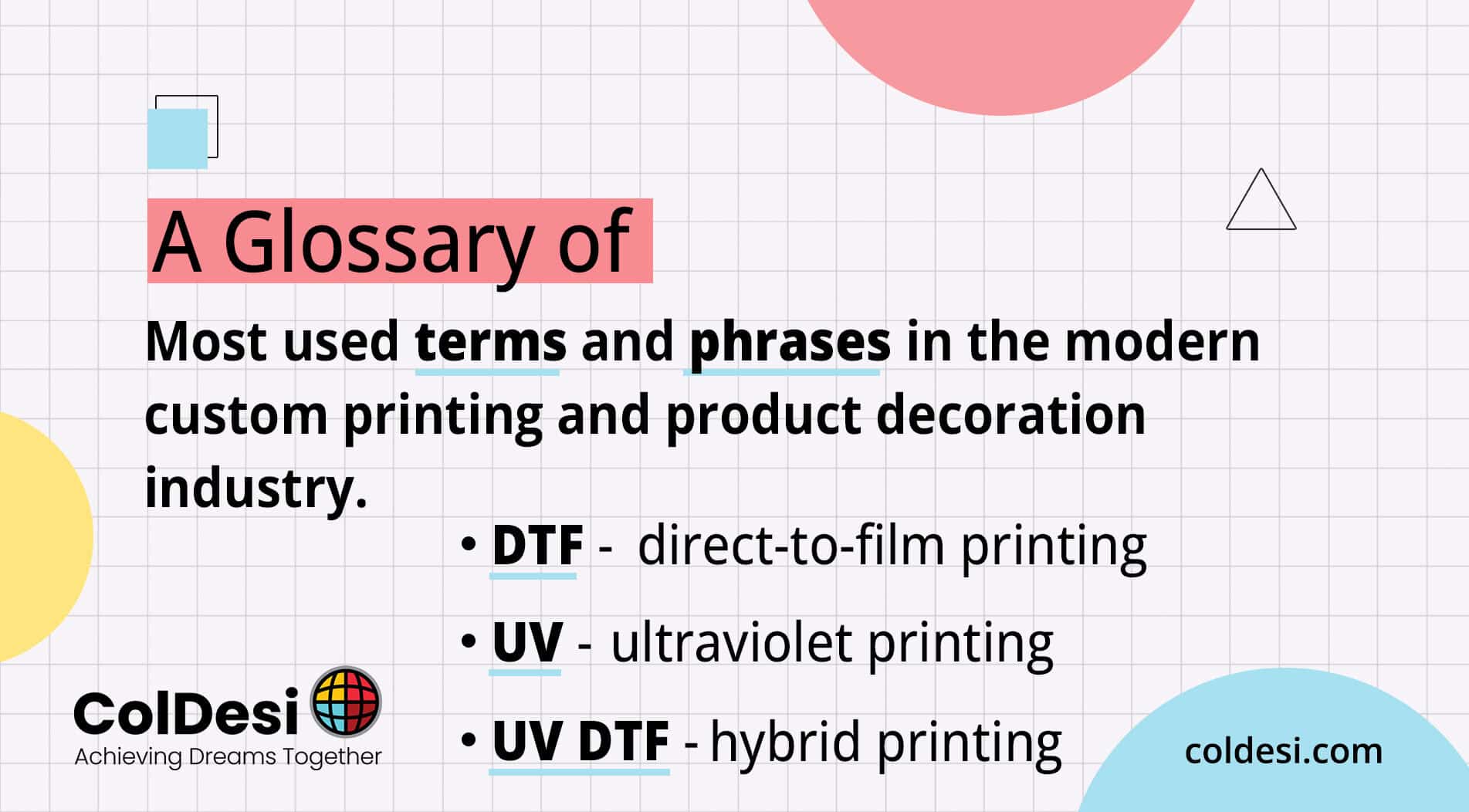

Our ongoing Embroidery and T-Shirt Printing education programs let you learn at your own pace. There’s a lot to learn to get your business off the ground and we’ve made every effort to make that training accessible and easy to obtain. ColDesi, Inc. has the industry’s largest online embroidery and direct to garment printer support database that offers not only repair and maintenance support, but loads of articles on starting and marketing your embroidery or DTG Business. Our Video support is growing, with videos being added weekly. Video Training is by far the most helpful form of instruction and can bend that learning curve so that you can start making money instead of trying to figure out your equipment.

Most Experience

Our employees are experts in the industry. With over 100 years of combined experience they have the knowledge to help your business be a success by answering any questions you may have or provide you with the right resource to turn to.