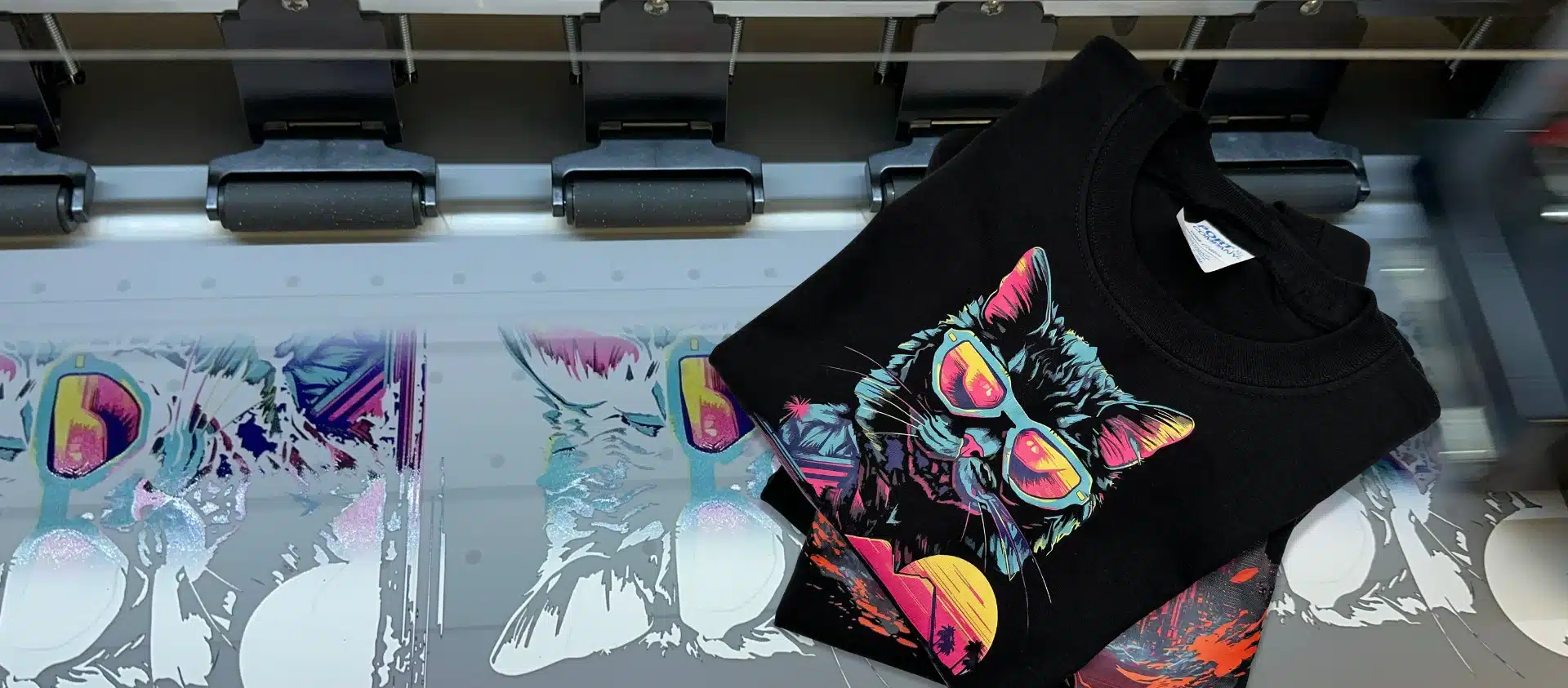

DTF Printers

There is no better way to produce amazing quality t-shirt transfers - especially at high volume.

New Year Specials Save Up to $2000 off Direct to Film Printers

ColDesi DTF Printers - Direct to Film Printers

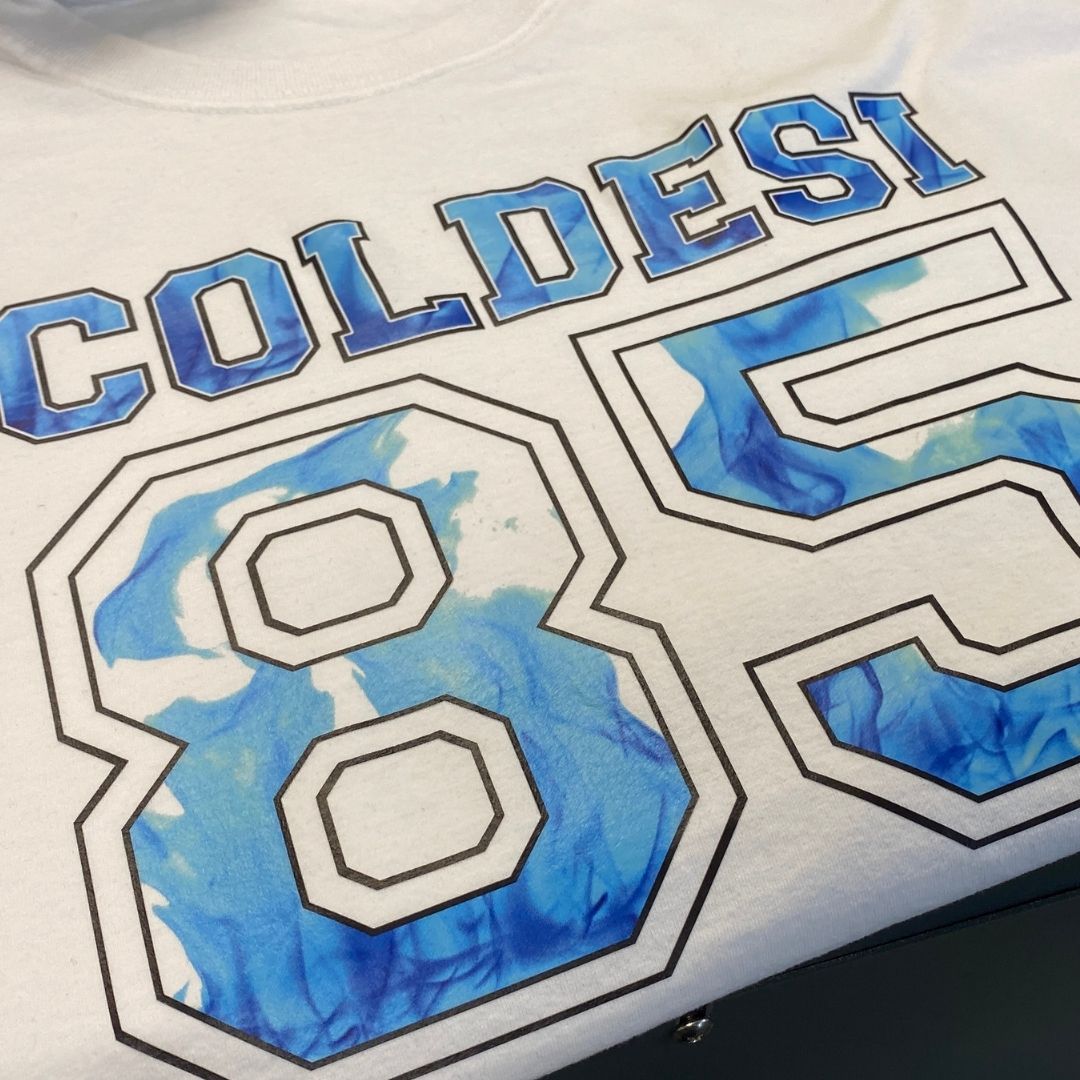

DTF or Direct-to-Film printing is a way to make very high-quality, full-color digital transfers for application to fabrics of all kinds. ColDesi DTF Printers can help you get work out quickly with great quality.

The DTF printing process offers a range of benefits for custom apparel printing. It produces crisp and durable prints on almost any garment, even on dark fabrics.

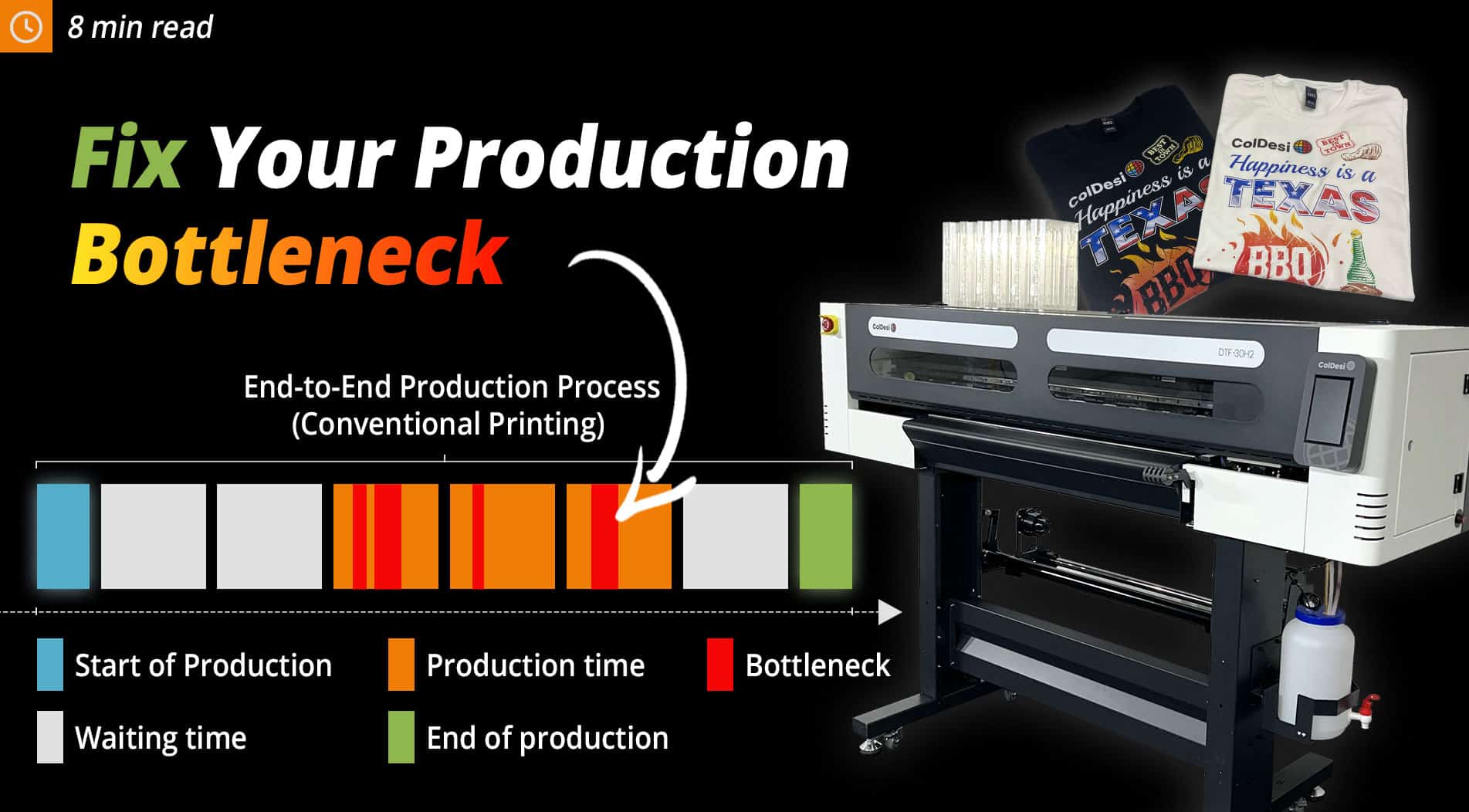

The core advantages of direct-to-film and of the high-volume direct-to-film printers that you’ll find here include:

- Wash fastness – these transfers last like screen printing

- Stretch – not only do the DTF printer transfers stretch along with the fabric, it snaps back into place beautifully

- Flexibility of materials – you can apply DTF printer transfers to any fabric, including blends, nylon, or heavyweight canvas, without compromising print clarity

- Very low application time – in most cases, transfer application to a t-shirt is a 15-second heat press

- VERY high-speed production – between 100 large shirt front transfers per hour (55 linear feet/hour) and 300 or more large shirt front transfers per hour (up to 150 linear feet/hour)

Watch this video to see us complete a 40 shirt + sample order using DTF printing equipment!

DTF T-Shirt Print Award Winner

ColDesi’s expertise and quality supplies (ink, DTF film, and adhesive) created the 1st place winning DTF transfer in "Best Print Quality in the DTF T-Shirt Contest" | Print United 2024. Judging based on Color Accuracy, Softness/Feel, Stretch, & more.

Speak with an expert. Call 877-793-3278

Applying the Adhesive to the Custom DTF Transfer Prints

It’s the unique powder adhesive coating that gives DTF prints their signature soft touch. Instead of thick transfer films or vinyl, the direct-to-film process has only two ingredients: ink and a thin coating of powdered adhesive.

The soft hand of ColDesi DTF is the holy grail of custom apparel. Unlike traditional film transfer or vinyl methods, the result feels natural across a wide range of textile printing materials. It’s never been possible to get the incredibly soft feel of half-tone screen printing in a transfer process. But with a DTF printer, you get all that and more.

The DTF powder adhesive is moisture-seeking, so it draws itself into the ink of the print and chemically bonds to form a strong, permanent adhesive that sticks extremely strongly to both cotton and polyester fibers.

The superior printing ability and the versatility of the process make DTF (Direct-to-Film) the most efficient and cost-effective method for consistently achieving high-quality prints on demand.

Number One in DTF

Since 1978 – Over 30,000 – 5 star Reviews – USA Support & Training

ColDesi is an awesome company with incredible support.

James S.Great team at ColDesi. Very knowledgeable and helpful.

Cole C.I just purchased my new DTF printer a few weeks ago. The training videos were excellent.

Brooke G.Best customer sales and support I've experienced!

Brandy M.10000/10 recommend!

Jonathan J.Excellent support and very patient. Willing to put the time in to help us get everything setup and working to our satisfaction.

Steve R.Largest DTF dealer in the U.S.

More DTF printers operating nationally than anyone else.

New Year Specials Save Up to $2000 off Direct to Film Printers

ColDesi DTF 12H2

$12,995

$10,995

Finance as low as $199/mo.*

Dimensions:

Printer only: 31″ x 39.5″

Shaker/Dryer: 50″ x 42.5″

Overall: 81″ x 24.5″

Resolution:

720 x 1080 DPI

720 x 1440 DPI

Speed:

25-30 linear feet

8 meters per hour

50 (8 x 10 in) transfers/hour

Print Optimizer Software – DTF Edition

Training & Support

Nationwide Technicians

ColDesi DTF 24H2

$25,495

$19,995

Finance as low as $360/mo.*

Dimensions:

Printer only: 29″ x 67.5″

Shaker/Dryer: 94.5″ x 36″

Combined: 123.5″ x 67.5″

Fits through a standard 36″ door, equipment on wheels

Resolution:

720 x 1800 DPI, 6-Pass

720 x 2400 DPI, 8-Pass

720 x 3600 DPI, 12-Pass

Speed:

Up to 45-55 linear feet

14 meters per hour

100 (8 x 10 in) transfers/hour

ColDesi Powder Shaker/Dryer with LCD panel – now 12% quieter

Print Optimizer Software – DTF Edition

OEKO-TEX ECO PASSPORT

Certified DTF Inks

Training & Support

Nationwide Technicians

ColDesi DTF 30H2

$27,495

$24,995

Finance as low as $450/mo.*

Dimensions:

Printer only: 29″ x 69″

Shaker/Dryer: 94.5″ x 42″

Overall: 123.5″ x 69″

Resolution:

720 x 1800 DPI, 6-Pass

720 x 2400 DPI, 8-Pass

720 x 3600 DPI, 12-Pass

Speed:

42.68 linear feet

13 meters per hour

180 (8×10 inches) transfers/hour

ColDesi Powder Shaker/Dryer with LCD panel – now 12% quieter

Integrated Fume Extractor

Print Optimizer Software – DTF Edition

OEKO-TEX ECO PASSPORT

Certified DTF Inks

Training & Support

Nationwide Technicians

ColDesi DTF 24H5

$34,495

$29,995

Finance as low as $535/mo.*

Dimensions:

Printer Only: 35.5″ x 78″

Shaker/Dryer: 94.5″ x 36″

Overall: 124.5″ x 78″

Fits through a standard 36″ door, equipment on wheels

Resolution:

720 x 1200 DPI, 4-Pass

360 x 3600 DPI, 6-Pass

Speed: Standard Color Gamut

Up to 158 linear feet

48 meters per hour

400 (8 x 10 in) transfers/hour

Speed: Expanded Color Gamut

Up to 145 linear feet

40 meters per hour

300 (8 x 10 in) transfers/hour

ColDesi Powder Shaker/Dryer with LCD panel – now 12% quieter

Print Optimizer Software – DTF Edition

OEKO-TEX ECO PASSPORT

Certified DTF Inks

Training & Support

Nationwide Technicians

ColDesi DTF 24H5E

$44,495

$39,995

Ask us about financing.

Print Heads:

5 Epson i3200 Print Heads

Printing Technology: Piezoelectric inkjet

Print Speed:

275+ linear feet per hour

500+ transfers

Print Method:

Variable DOD Using VSD

Print Width:

22.5 inches

Color Modes:

• CMYK and White

Ink Type: ColDesi DTF OEKO-TEX® ECO PASSPORT Certified Pigment Water Based Textile Ink

Ink Capacity:

500 ml Bottles

Print Media:

ColDesi 24″ x 328′ G Series Hot Peel PET Transfer Film

Media Transmission: Automatic Tension System (Dancer System)

Transmission Interface: USB

Included RIP Software: ColDesi’s DTF Print Optimizer Software

Supported OS: Windows 10 PC (or greater)

Certifications: OEKO-TEX ECO PASSPORT Certified Ins

Training & Support

Nationwide Technicians

*Financing available with 20% down and approved credit (subject to credit approval).

Our OEKO-TEX® ECO PASSPORT-certified DigitalHeat FX Inks from ColDesi help you comply with global safety regulations and supply chain requirements. We are proud to offer DTF Ink certified with the OEKO-TEX Eco Passport, an independent certification system for chemicals, colorants, and auxiliaries used in the textile and leather industry. Through a multistep process, each ingredient in the chemical product is analyzed to ensure it meets the requirements and is not harmful to human health.

This certification demonstrates our commitment to environmental responsibility and safety. Whether you're using a DTF transfers printer with high-output RIP software, or expanding your workflow with a curing oven and other essential accessories, ColDesi customers can take pride in knowing these products adhere to the highest standards—driving the entire industry forward on its sustainable journey.

Have questions about OEKO-TEX? Learn more from the OEKO-TEX website.

Listen to Podcasts about DTF

Episode 159 – All About Direct-to-Film Printers

Direct-to-film printers are the most talked-about new products for 2024!

So the big questions are:

- What is direct-to-film (DTF)?

- What makes it different from other technologies

- Screen Printing/Transfers

- White toner Printing

- Sublimation

- DTG

- What are the differences between different DTF printers?

- What comments do you have about people who don’t prefer to jump into new technology due to risks of something that isn’t ‘proven?’ Should they wait? Is it time to jump in? Who should jump in?

Financing Available

AdiaCapital.com

ColDesi has worked with Adia Capital as a trusted partner to provide financing opportunities for our customers and deliver sound advice about starting and operating a small business.

DTF Printer FAQs

Have more questions about DTF printers? ColDesi has answers.

Neither DTF or sublimation is a better printing method. They both have their own strengths and weaknesses. DTF printing is great if you need to work quickly and in relatively high volumes while sublimation is usually best for printing all-over designs on larger pieces of material. DTF printing is generally sharper in visual quality though it can feel stiff compared to sublimation printing.

Sublimation prints usually last longer than DTF prints because the designs are infused (sublimated) into the materials rather than being made of inks that are transferred onto the material. That being said, high-quality DTF prints will still last for a long time.

We believe in privacy and communicating in the best way for your business. By completing the above form, you agree to be contacted by ColDesi Inc through phone calls, emails, and text messages. You can opt-out of emails with unsubscribe links or opt-out of texts by replying STOP at any time.

Outstanding Support! Very quick respond time.

Gabriele F.