Is there anything you need to know or be aware of when buying a DTF printer with a powder shaker/dryer unit?

You bet!

While direct-to-film printers are well thought out and engineered for maximum performance and ease of use, there are still a few areas where things might need to be worked out and tweaked from the user’s perspective.

So, before you hit that “Buy Now” button, take a moment to read this buying guide.

You can think of this as your DTF Printer 101, where we’ll break down all the essential things to know about DTF. We’ll cover everything from the space you’ll need to the supplies and consumables required, and of course, how this technology works and why it’s creating such a buzz.

We’ll also dive into costs beyond the purchase, as well as tips on upkeep, maintenance, and care to ensure your printer lasts for years.

All in the hope of better educating and informing you while helping you find the perfect fit with our ColDesi’s line of DTF direct-to-film printers.

With these points in focus, let’s jump right in!

Understanding the Basics:

What is DTF, How it Works & What SetsIt Apart from Traditional Printing Methods

Rate, from 1 to 10, how much do you know about DTF printing? If you’re above a 5 or already familiar with the basics, feel free to skip ahead to the next section.

Still, it might be worth staying—you could still learn something new or get a quick refresher of what you already know!

With that preface, let’s start with the basics: What is DTF? DTF is an acronym, short for direct-to-film printing; or, in simple English, a method of transferring designs onto fabrics using a special film.

It works a lot like white toner printing, so if you’re familiar with that, you’ll get the hang of this in no time.

Similar to how you would start with traditional printing methods, the process begins by bringing in your artwork (e.g., patterns, graphics, text, etc.).

Once you’ve set everything up and configured the settings the way you wish, you simply press ‘Print’ (or ‘Start’) like you would with any other printer.

With this process underway, the printer will then pull the translucent PET (polyethylene terephthalate) film over to the print head for printing.

Your design will get printed in a mirrored position, layer-by-layer. The color will be laid down first, followed by the application of white ink.

After the ink is applied, the DTF film will pass through a shaker/dryer unit. This unit deposits a type of polyurethane (TPU) hot-melt adhesive powder onto the back of the film (and ink), and to ensure even spreading, it is shaken by a vibrating mechanism.

Finally, the DTF film enters the heating chamber. Here, it heats up the hot-melt glue and finishes curing the inks themselves, so that when it comes out the back, it’s ready for use.

At this point, you have a few options for the transfer. Since it’s ready to be pressed, you can apply it to your garment right away using a heat press. Alternatively, you can save it for later or list it for sale online if you don’t need it immediately.

And there you have it – a simplified version of how direct-to-film (DTF) printing works and how it sets itself apart from traditional printing methods.

But let’s pop the hood and take a look at the parts, components, and add-ons that pair (and come) with the DTF printer to see how everything comes together and fits into the system.

What Typically Comes with a DTF Printer Purchase?

If you’re just about to buy a DTF printer, you’re probably asking yourself, “What comes in the box?”

We thought it’d be fun to unpack that for you and take a look at the main parts, accessories, and goodies that come with your ColDesi DTF printer.

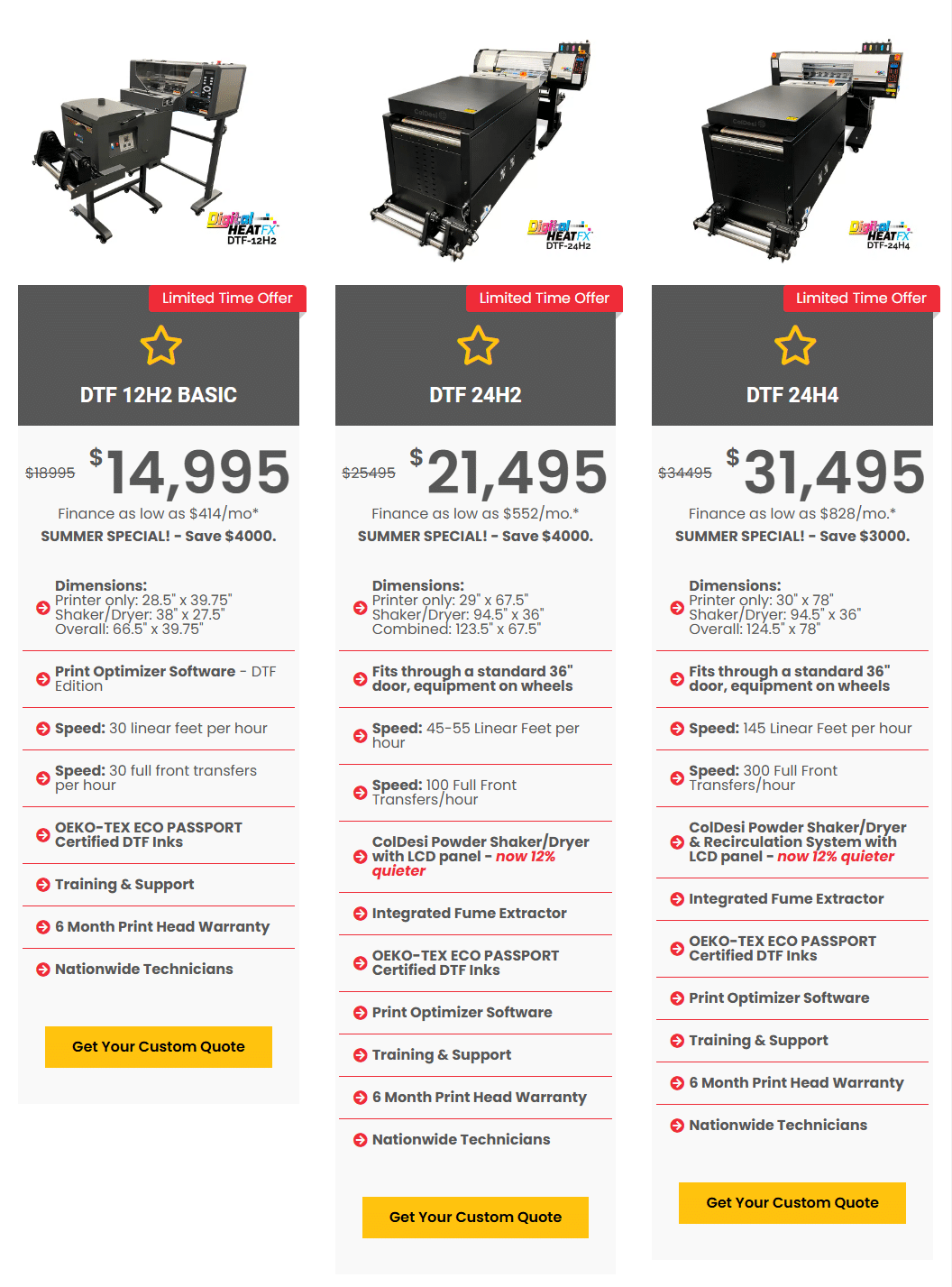

One quick thing to keep in mind: ColDesi’s line of direct-to-film (DTF) printers includes three models—the 12H2, 24H2, and 24H4. There are different options and kits available, so what’s in the box may vary depending on the one you choose.

DTF Printer Unit: The star of the show is the DTF printer itself. Its chassis houses everything from the print heads and ink system to the film feeding mechanism and essential components like the control board, sensors, and motors.

Set of DTF Inks: Typically provided in bottles or bags, these inks use the CMYK+W color model and are OEKO-TEX® ECO PASSPORT certified, confirming they are free from harmful chemicals and safe for both people and the environment.

PET Film: Polyethylene terephthalate (PET) transfer film, commonly known as PET Film, is designed to work with the ink formulations used in these printers. It features special ink-absorbing and heat-resistant properties, and its translucent nature allows you to see the design underneath the film when you heat-press it onto your garment.

DTF Adhesive Powder: DTF powder adhesive is usually a fine, white powder applied to the PET film over the still-wet ink immediately after printing, using the shaker/dryer unit. This unit then applies heat to melt the adhesive and to cure and dry the ink. This process fuses them together, forming a strong, cohesive layer that bonds to the garment when applied.

Powder Shaker/Dryer Unit: As mentioned previously, the PET film passes through a section where adhesive powder (typically a fine thermoplastic polymer powder) is evenly applied to the wet ink. Once the powder is applied, a shaker mechanism removes any excess powder from the film. A side note: the higher-end DTF 24H4 model features a built-in powder recirculation system that collects excess powder for refilling and reuse.

Integrated Fume Extractor: DTF 24H2 and 24H4 printers include a dedicated DTF fume extractor that helps absorb and extract smoke or fumes generated during the printing process.

RIP Software: All three DTF printers include Print Optimizer software, which allows you to manage and control your printing projects. With this software, you can fine-tune colors, resize or reposition artwork, and handle print jobs efficiently.

Training & Support: ColDesi’s DTF printers come with training and customer support to help you and your people quickly master the new system.

DTF Printer Costs: What You'll Pay Now and Beyond the Purchase

What does a DTF printer really cost? Well, the answer to that varies a bit depending on which model you go with.

So, let’s take a look at that, as well as ongoing expenses for supplies, raw materials, and other related costs you should factor in and plan for.

Now, we briefly talked about this before, but as a refresher, there are three DTF printer models in the ColDesi series—12H2, 24H2, and 24H4. There are various options and kits, with pricing that reflects their features and value.

In the graphic below, you’ll find a comparison between all three printers.

So, with that out of the way, the next financial consideration is the ongoing cost of supplies you’ll need to order and reorder after purchasing the printer.

Like most things these days, prices can fluctuate, so instead of providing specific numbers, we’ll give you a list of the supplies and raw materials you’ll need for most of your projects.

Some of the items on this list may look familiar, as we briefly covered them in the previous section.

- DTF Transfer Film

- DTF Ink

- Adhesive Powder

- Heat Press Machine

- Cleaning Supplies

- Finishing Sheets

- Heat Tape

- Wholesale Blanks

As you can see, the cost of the printer, along with daily supplies, can really add up. But these are just the everyday expenses of running a business, and that’s not even counting things like rent, wages, utilities, and other equipment.

Of course, that shouldn’t scare you away from buying a DTF printer, as the potential upside outweighs the costs.

The only thing left to figure out is: Where can you buy all these supplies and raw materials?

There’s only one place to go for all things DTF-related, and that’s www.colmanandcompany.com!

To learn more about ColDesi’s line of direct-to-film (DTF) printers, visit coldesi.com and Live Chat with a Pro below, or call 877.793.3278.