What if you could print on almost any material?

Even the ones that usually give you trouble, like nylon, polyester, or dark, synthetic, or stretchy fabrics.

You know… all the materials your customers love to choose while you quietly pray they’ll pick something ‘’normal.’’

Traditional methods can make those fabrics tricky, or nearly impossible, to work with. Pretreats, underbases, cracking, fading… it’s a lot of work for results that often fall short of your expectations.

If you’ve been in the industry for longer than ten minutes, none of this is news.

Luckily, there’s now a practical way to make printing on these so-called “problem” fabrics simpler and far more reliable.

By now, you’ve probably already heard the term DTF everywhere: on social media, at trade shows, in ads, and in discussions about transfers, printers, supplies, or anything else with DTF in the name.

And that’s not because it’s trendy. It’s because DTF solves problems decorators have struggled with for years.

DTF works differently from traditional methods. It bonds your design to the fabric in a way that’s more forgiving than traditional methods, and it works on almost any material, not just cotton.

Even those “impossible” fabrics come out looking better than anything you’ve printed on plain cotton.

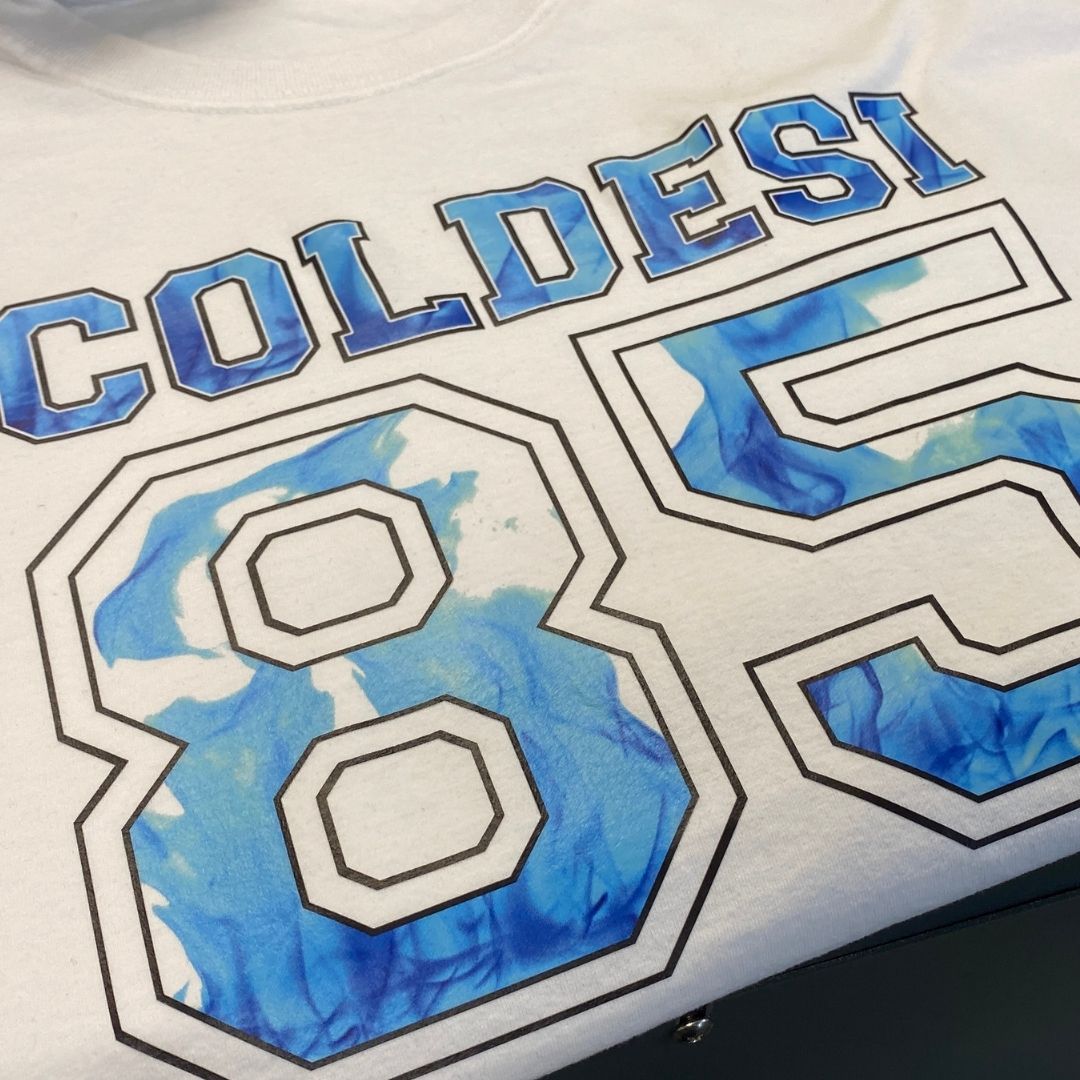

We’ll show you photos to prove it, so you can see the results with your own eyes.

By the time you’re done reading, you’ll learn why some fabrics are so difficult to print on, how DTF films and inks really work, which materials DTF transfers work on, and why so many businesses are switching to it.

We’ve got a lot of work ahead of us, so let’s roll up our sleeves and get started.

How DTF Makes Printing on Dark, Blended, and Synthetic Fabrics Easy

Before we get into the solution, let’s take a step back and look at the problem from the birds-eye view. Why does it exist at all? And why are dark, blended, and synthetic fabrics so tricky to print on?

The issue comes down to three main challenges: adhesion, opacity, and durability.

Adhesion – Traditional inks, like those used in screen printing or DTG (Direct-to-Garment), often have trouble sticking to synthetic fibers like polyester or nylon. Why? It’s simple. These inks are formulated to be absorbed by natural fibers like cotton. Synthetic fibers such as polyester or nylon are hydrophobic, meaning they repel water and do not absorb ink well.

Opacity – On dark fabrics, even if the ink adheres, colors often appear dull or muted because most inks are semi-transparent. Achieving vibrant prints usually requires a white underbase or multiple layers of ink.

Durability – Even if you somehow get the ink to stick and appear vibrant, the print may not last. Repeated washing, stretching, and everyday wear can lead to cracking, fading, or peeling because the bond between ink and fabric isn’t strong enough

This is where DTF (Direct-to-Film) printing comes in. Instead of printing directly onto the garment, designs are first printed onto a specialized film. A powdered adhesive is then applied to the printed areas. When heat and pressure are applied using a heat press, the adhesive melts and permanently bonds the design to the fabric.

The result is a print that’s vibrant, opaque, and durable.

While this is a simplified overview of the process, it explains why DTF printing has become such an effective solution for decorating dark, blended, and synthetic fabrics.

With this foundation in hand, we can now look at the science behind ColDesi’s DTF inks and films and see what makes them so effective.

The Science of ColDesi’s DTF Inks & Films

Before a single transfer is printed or a shirt ever touches the heat press, hundreds of quiet decisions have already been made behind the scenes. Experts in color science, material engineering, and printing technology have thought through every detail. From the ink’s chemistry to the way the film holds it, every element is carefully planned, and every choice is made long before your design becomes something you can hold in your hands.

This level of precision isn’t an accident. It comes from understanding exactly how every material interacts in the printing process, from the inks, to the films, to the fabric it ultimately bonds with.

If you’re new to this, direct-to-film (DTF) systems use liquid, water-based pigment inks. These inks operate on the CMYK + W color model.

Before you reach for a dictionary, that simply means five ink colors, Cyan, Magenta, Yellow, Key (black), and White, are used to produce a wide spectrum of colors for your custom designs.

But these aren’t your everyday inks. They’re specially formulated and calibrated to bond permanently with polyethylene terephthalate (PET) transfer film and, ultimately, with fabric.

Polyethylene terephthalate (PET) transfer film, commonly known as PET film, is designed to work hand in hand with these ink formulations. It features special ink-absorbing and heat-resistant properties, and its translucent nature allows you to see the design beneath the film as you heat-press it onto your garment.

And here’s a fun fact. PET is a thermoplastic polymer that can be melted down and remade into new products.

Just as important, these inks are OEKO-TEX® ECO PASSPORT certified. That certification confirms they’re free from harmful chemicals, safe for both workers and wearers, and more environmentally responsible than many traditional printing methods.

And how do we know all this? We bottle our inks right here in Clearwater, Florida, our hometown.

Now look, we know you didn’t come here for a chemistry lecture. Next, we’ll show real photo examples of DTF transfers applied to different substrates, highlighting how resolution, clarity, and color remain consistent across different substrates. While we’re at it, we’ll also cover the types of fabrics and surfaces where DTF transfers can be applied.

Wondering what DTF supplies and products should be on hand for when you want to print on apparel? Here’s a full checklist.

DTF Transfers: Photos & Compatible Materials

Now it’s time to see DTF transfers up close. We’ll show real examples of designs on different fabrics and surfaces so you can see how colors stay vibrant, details remain sharp, and results are consistent across materials.

Before that, let’s look at the most common applications of DTF and the types of materials it can be applied to, giving you a clear view of its versatility. We’ll also share creative ideas for customization, and the industries where DTF printing is widely used.

As expected, DTF film can be transferred to a wide range of materials and substrates. However, it has limitations: extremely uneven surfaces, materials with certain coatings or finishes, or items that can’t tolerate high heat may produce poor results.

Other than that, with DTF you can print on both traditional and non-traditional substrates:

Industries:

- Apparel & Fashion

- Promotional Products & Branding

- Textile and Home Decor

- Sports & Teamwear

- Workwear

- Corporate & Event Merchandise

- Educational Institutions

- Creative and Artistic Markets

- Custom Gifts & DIY Projects

- Product Labels and Packaging

- Custom Gifts & DIY Projects

- Merchandise, Accessories & Specialty Items

From apparel and promotional products to home decor and corporate branding, DTF enables you to tap into markets that were previously out of reach.

Fabric Compatibility:

- Combed Cotton

- Ring Spun Cotton

- Organic Cotton

- 100% Polyester

- Poly‑Cottons (Cotton/Poly blends)

- Tri-Blends (Cotton/Poly/Rayon)

- Polyester-Spandex / Lycra

- Leather / Faux Leather

- Nylon

- Denim & Canvas

Ideas for Customization:

- T-Shirts

- Brand Tags

- Polos

- Sweatshirts & Sweatpants

- Bags (e.g., tote bags, backpacks, purses)

- Aprons

- Hats and Caps

- Socks and Gloves

- Flags

- Sports Uniforms

- Company Dress Shirts

- Running Shorts

- Fishing & Boating Shirts

- Uniforms (e.g., for sports teams, workwear, or uniforms)

- Mousepads

Taken together, the range of fabrics, products, and industries shows just how versatile DTF printing really is.

Whether you plan to create apparel, accessories, or promotional items, the possibilities are nearly limitless.

The whole idea is that DTF gives you a way to reach new markets and expand your product offerings, all while being easy to use, fast, and cost-effective.

You can put your designs on everything from apparel and accessories to home goods and beyond.

The benefits of that are huge, and we’re going to dive into them next.

How You Can Benefit from Consistent Quality Across Materials

We’ve come a long way since we started, haven’t we?

We’ve talked about the problems in apparel and product decoration, the solutions, the materials, and, most recently, the opportunities that DTF creates.

And now we arrive at the only question that really matters:

So what?

What does any of this do for you, or your business?

Well, if you read between the lines, it means this: every idea you have, every design you dream of, and every product you imagine can be produced, all with a single piece of equipment.

You don’t need multiple machines or a whole new setup every time you switch materials.

Maybe one day you want to work with cotton, polyester, and blends.

The next day, blends and performance fabrics.

And the day after that, light or dark garments and even non-traditional substrates.

If you know, for a fact, that your prints will look consistent no matter the material, the color, or the texture, it takes a huge weight off your shoulders.

And it does the same for your team. Everyone can breathe a little easier and actually enjoy the work they’re doing.

It makes the whole process feel smoother, less stressful, and even a little more exciting. And honestly, when your team sees that confidence in action, it spreads. Everyone starts trusting the process and each other a little more.

But this freedom is just one aspect. Consistent quality across various materials brings a host of practical benefits for you and your team:

Simplified Training and Onboarding: It makes training new team members simpler, because the process works the same way every time.

Reduced Waste and Costs: Fewer misprints and errors mean you save on materials and time, directly improving your bottom line.

Scale Without Limits: When outputs are predictable, expansion, new markets, and bigger projects become achievable instead of intimidating.

Faster Innovation: Reliable results let you test new ideas, launch products, and pivot quickly, so speed becomes a competitive advantage.

Protect and Grow Your Reputation: When clients know you always deliver flawless results, they buy bigger, commit faster, and stay loyal longer.

These are just some of the potential benefits of consistent quality. You could add plenty more to that list, but the point is already clear.

Over time, it improves morale, efficiency, profitability, and client trust.

It’s practical. It’s measurable. And it’s the single factor that makes everything else in your business run smoother.

But enough of that, let’s tie it all together in our final thoughts section.

Final Thoughts: Bringing It All Together!

You’ve made your way through quite a bit of content—and hopefully, you’ve also watched the accompanying video clips and explored the supplementary how-to articles and guides we linked.

But if you haven’t gotten to all of that yet and you’re short on time and just need the gist, our overall view and the main points we talked about today can be summed up in a few sentences.

DTF, unlike other printing methods, works on almost any fabric and color without needing pretreatment, underbases, or extra prep. It handles full-color artwork, gradients, and fine details with ease, and the transfers themselves can be made ahead of time, sold, or stored for later use.

That flexibility alone changes how a lot of shops think about production and inventory.

You can press on pretty much any item that can tolerate heat—and that’s what makes DTF such a practical option for a wide range of products.

From here, all that’s left is deciding which DTF printer fits your workflow and production needs.

You can look through our full lineup of DTF printers or reach out to someone on our team for guidance.

See you on the other side!