The Next-Generation Commercial Direct-to-Film Shaker/Dryers from ColDesi

Having the best DTF printing shaker/dryer is essential for any customization business. It directly impacts the quality, efficiency, consistency, and profitability of the business. It is an investment that enhances operations and positions the business for long-term success.

ColDesi’s state-of-the-art POW and POWR Direct-to-Film Shaker/Dryers are tailored to meet the specific requirements of businesses of all sizes. They offer unparalleled customization options when paired with the ColDesi DTF-24H2 or DTF-24H4 printers.

If your custom apparel business is looking to optimize production, these new direct-to-film shaker/dryer systems promise to deliver on all fronts. In this article, we will explore the groundbreaking features of these direct-to-film shaker/dryers, their impact on the DTF printing process, and how they are setting a new standard in the industry.

Customizing Your DTF Printing Experience

One of the standout aspects of the new shaker/dryer systems is the ability to tailor them to your specific business needs.

Customers can now choose between the POW and POWR models, both of which can be paired with either the DTF-24H2 or DTF-24H4 printers.

This flexibility allows businesses to customize their printer and DTF printing shaker/dryer combination based on their operational demands and budget constraints.

The 24H2 and 24H4 printers are known for their exceptional print quality, speed, and reliability.

When paired with these new direct-to-film shaker/dryer systems, the result is a fully optimized setup, providing business owners who learn, a shaker/dryer solution that enhances productivity.

Whether you need a system that manages high-volume production or one that offers precise control for intricate designs, these shaker/dryers are the perfect solution.

Enhanced Safety with Integrated Fume Extraction

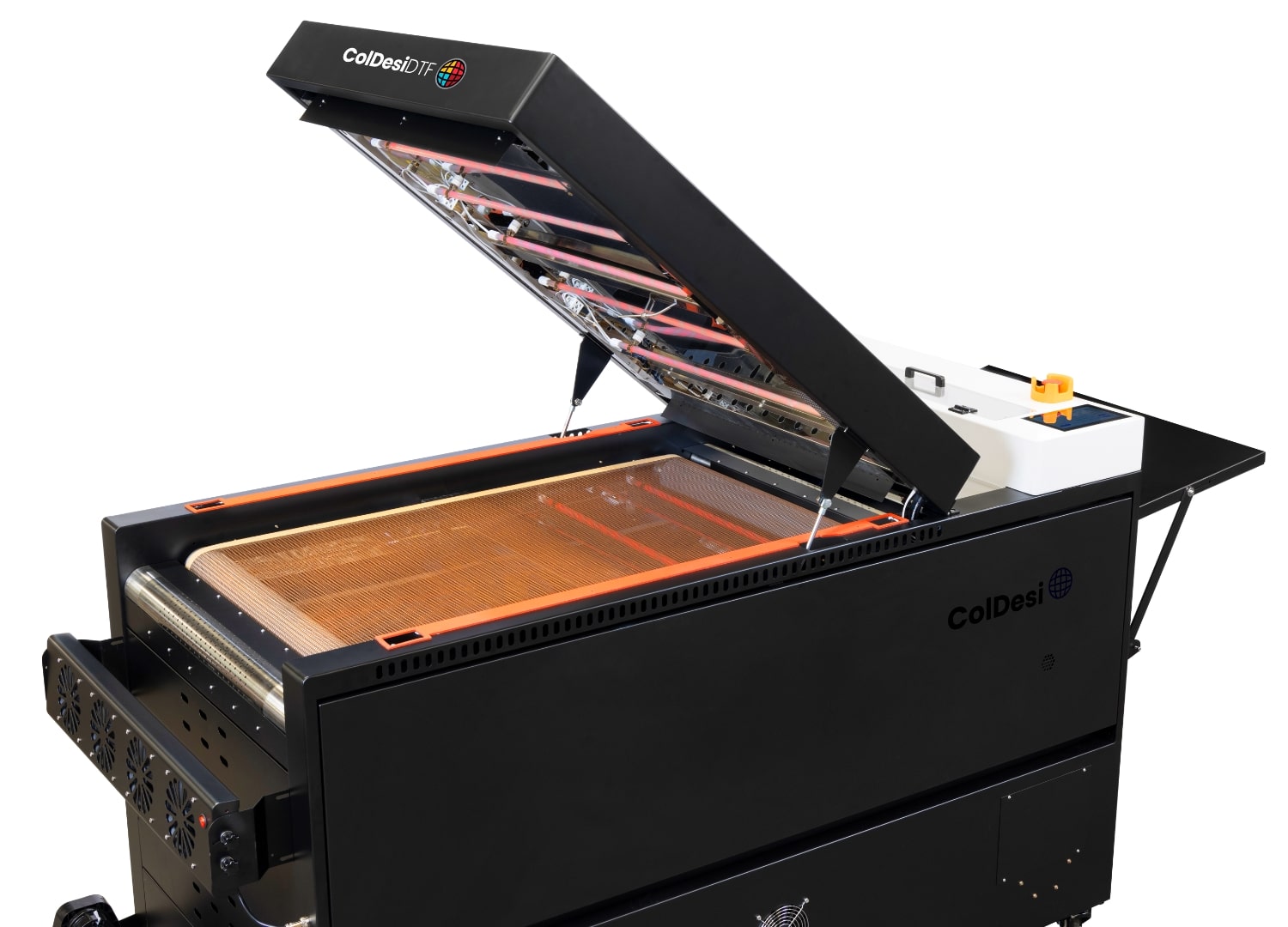

The DTF printing process involves the use of chemicals and heat, which can pose safety risks if not responsibly managed. In any printing operation, safety should be a top priority.

These DTF printing shaker/dryers address this concern head-on by integrating the fume extractor. They are designed to filter harmful oil fumes generated during the drying process, ensuring a cleaner, smoke-free working environment.

This not only contributes to the health and safety of operators but also improves the overall quality of the processed products.

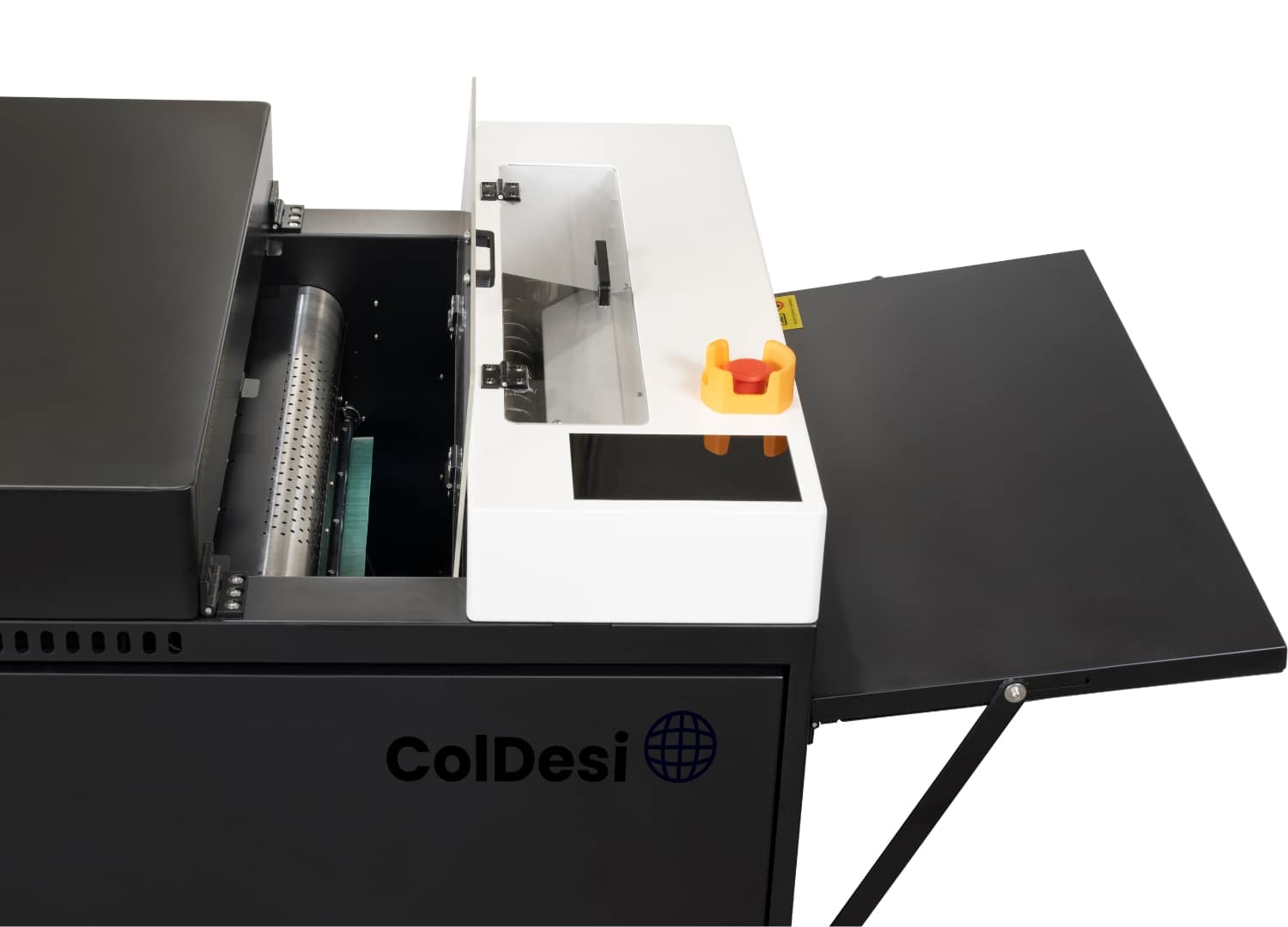

The integrated fume extractor is a game-changer for DTF printing. In traditional setups, external fume extractors are often required, which can be cumbersome to install, maintain, and operate. With the new built-in system, these concerns are eliminated. The integrated design simplifies setup and maintenance, providing users with a more streamlined and efficient experience.

The absence of an external extractor means fewer components to manage, reducing operational disruptions.

Auto-Recirculation System: Maximizing Efficiency and Reducing Waste

One of the most innovative features of the POWR is the auto-recirculation system. This system automatically collects excess powder during the printing process and recycles it for future use.

The auto-recirculation system not only reduces the amount of waste generated, but it also minimizes the need for manual intervention.

In traditional DTF setups, excess powder needs to be manually collected and refilled. This process is time-consuming and prone to spills and messes.

The auto-recirculation system eliminates these issues, ensuring a cleaner and more efficient workspace. This innovation results in lower operating costs and a reduced environmental footprint.

Discover how eco-friendly direct-to-film printers are transforming the digital printing landscape! Explore the cutting-edge technologies that help reduce waste, minimize energy consumption, and promote sustainable practices in custom apparel printing.

Learn how choosing an eco-friendly DTF printer can enhance your business’s environmental impact while maintaining top-notch print quality and efficiency.

User-Friendly and Versatile Design

ColDesi’s commitment to user convenience is evident in the new shaker/dryer systems. Designed with the operator in mind, these machines are both powerful and easy to use.

A newly integrated LCD panel allows users to control and monitor the system with ease, ensuring that even those with minimal technical experience can operate the machine effectively.

Despite their robust capabilities, these shaker/dryers have been engineered to fit into a wide range of workspaces. Measuring 94.5″ x 36″, they are compact enough to fit through a standard U.S. door frame, making them accessible to businesses of all sizes.

Now, companies don’t need to make extensive modifications to accommodate new equipment.

Revolutionizing the DTF Printing Process

These direct-to-film shaker/dryers represent a significant leap forward in the industry. By combining enhanced safety features, advanced automation, and a user-friendly design, ColDesi has set a new standard for what businesses should expect from their DTF printing equipment.

This commitment to innovation is what sets ColDesi apart from the competition.

The custom apparel industry is experiencing rapid growth, driven by the increasing demand for personalized products and on-demand printing services. As businesses strive to meet this demand, the need for efficient, reliable, and scalable printing solutions has never been greater.

ColDesi’s Direct-to-Film Shaker/Dryers are designed to meet the needs of this growing industry, offering customizable equipment solutions tailored to different business models. The POW and POWR models provide the flexibility that modern businesses require.

Features like the auto-recirculation system and integrated fume extractor make these shaker/dryers leaders in sustainability and safety.

As consumers become more environmentally conscious, businesses that prioritize eco-friendly practices will have a competitive edge. By reducing waste and minimizing environmental impact, ColDesi’s new shaker/dryers help businesses align with these values while maintaining high productivity.

In the fast-paced world of customization, staying ahead means embracing innovation. Explore how direct-to-film printing solutions offer a competitive edge in the fast fashion industry. From rapid production times to unmatched design flexibility, DTF technology empowers manufacturers to meet the ever-changing demands of consumers with speed and efficiency. Discover how DTF printing can enhance your production process, reduce costs, and keep your brand at the forefront of the fashion market.

A Future-Proof Investment

Investing in new equipment is a significant decision for any business. It’s essential to choose solutions that will stand the test of time. ColDesi’s new direct-to-film shaker/dryers incorporate the latest technological advancements to ensure long-term reliability and performance.

As the industry evolves, these shaker/dryers provide a solid foundation for future growth, ensuring that your business can stay ahead of the curve without the need for frequent equipment replacements. Backed by ColDesi’s renowned customer support and training services, when you invest in a ColDesi product, you’re not just buying a machine—you’re gaining access to a wealth of resources that can help your business succeed.