Are you starting to feel like your current printing method is holding your business back?

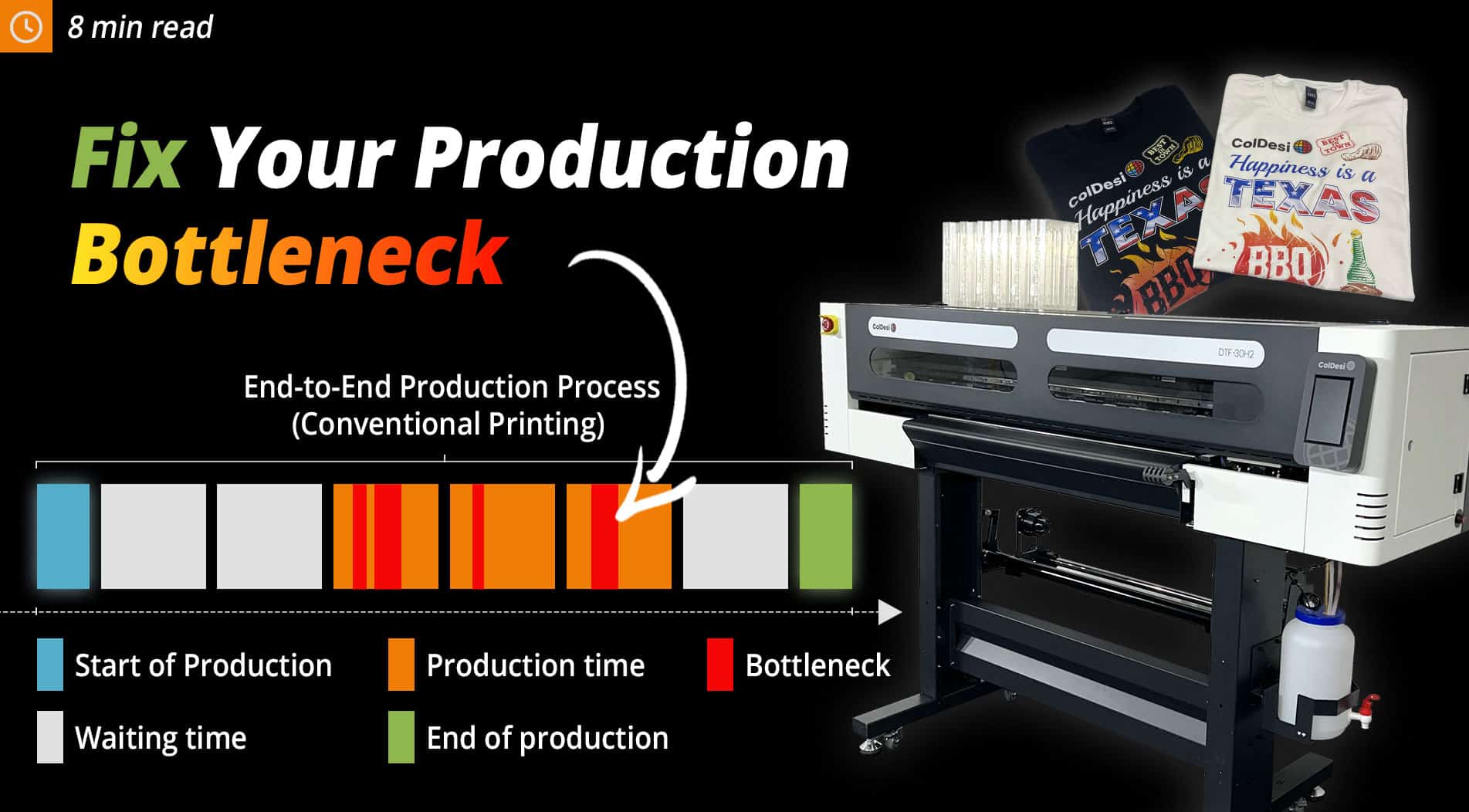

Most apparel businesses reach that point eventually: the method they’ve relied on for years starts dragging down production with long setup times, jobs piling up in queues, and staff waiting around for equipment to catch up.

Custom shops, screen printers, private-label brands… everyone hits that point where the old workflow becomes the thing that slows growth instead of supporting it.

And when that happens, it does not matter how great your team is. You end up losing clients to shops that can turn work around faster than you can.

That’s the moment when industrial-grade DTF stops looking like a “nice upgrade” and starts looking like the only practical way forward.

But here is where many businesses take a wrong turn.

They look for DTF equipment the same way they compare hobby or entry-level equipment: by looking at sample prints, surface-level specs, or whatever seems impressive in a demo or brochure.

That might work when you are only doing a handful of orders a day, but it does not tell you anything about how the machine performs when you are running it hour after hour and need consistent, repeatable, all-day output.

When you’re running real volume, the question changes.

It’s not “Does the first print look good?” It’s “Does print 1,000 still look the same?”

That’s the difference between equipment that’s built for show and equipment that’s built for production.

And once you recognize that difference, you understand why so many growing shops eventually make the jump to ColDesi’s lineup of industrial-grade DTF printers.

This brings us to why you’re here.

You’re not just here to learn what DTF is—you’re here to understand why it matters for the stage your business is in, and whether it solves the specific growth problems you’re facing.

So the rest of this piece will walk you through the practical advantages of industrial DTF. We’ll look at where traditional methods start slowing you down, and how ColDesi’s DTF printers solve those choke points.

You’ll also see real results from shops that already made the switch.

By the end, you’ll be able to determine whether industrial DTF is the upgrade your business needs to grow at the pace your customers now expect.

Let’s begin.

Why Traditional Printing Can't Keep Up with High Volume Production

Traditional printing methods like DTG or screen printing have been around for years, and there’s no denying they’ve been reliable, consistent options. So what’s the issue?

The core problem, as we touched on earlier, is that these traditional methods simply can’t keep up with high-volume production. And if you’re reading this, there’s a good chance you’ve already started to feel that pressure.

But that’s not the only problem. There’s a slew of others; setups take longer than you think, you’re constantly depending on people who already have too much on their plate, and then there’s the ongoing maintenance, the unexpected downtime, and the waste—screens, chemicals, test prints, it all adds up.

These annoyances are forcing you to make decisions you wouldn’t make if you had more capacity.

Instead of growing the business, you’re managing bottlenecks. Instead of testing new products, you’re wrestling with the same setup challenges. And sometimes, you’re turning down work you know you could take… if the process didn’t push back at every step.

This is usually the point where many shops tell themselves, “Well, that’s how printing shops work.”

But that belief is exactly what keeps the problem in place. It makes you assume the bottleneck is your team or your workflow, when in reality, it’s the technology itself.

And if the technology is setting the limits, your business can only grow to the edge of those limits—never past them.

So the question becomes: do you keep trying to push outdated methods harder… or do you switch to something that actually scales with you?

What you need now isn’t a faster version of the same old thing.

You need a technology that scales with your ambitions instead of pushing back against them.

Which brings us to the one solution that does exactly that: DTF.

How DTF Outperforms Traditional Printing in Just About Every Way

We’re past the primer where we covered the shortcomings of the old-school traditional screen printing methods, and now we know that a better, newer technology, DTF, outperforms them in almost every way.

But that raises a question: how exactly does it do that? And what makes DTF so much better?

That’s what we’re about to look at.

1. DTF Works on Practically Any Fabric

You can apply DTF transfers to almost any fabric—polyester, nylon, blends, tri-blends, canvas, and more.

That means you can create t-shirts, jerseys, hoodies, backpacks, aprons, and beyond. If the material can handle a heat press, DTF lets you put your design on it.

2. Full-Color, High-Resolution Prints

With DTF, you can print nearly anything you want—photos, logos, letters, text, fine details, and multi-color artwork. You can make it as detailed, and as colorful as you like! And whether it’s a photo-realistic design or a small, simple logo, what you see on your screen is exactly what shows up on the garment.

3. Lightweight, Portable Transfers That Store and Ship Easily

DTF transfers are flat, lightweight, and easy to store, ship, or move around the shop.

4. Minimal Waste and Maximum Efficiency

DTF keeps waste to an absolute minimum. You’re only laying down the ink your design actually needs, and the powder adhesive sticks only to the printed areas of the film. You use only the materials required for each transfer, which means way fewer supplies going in the trash.

5. Water-Based Inks

DTF printers use water-based pigment inks, which are more environmentally friendly compared to solvent-based alternatives or plastisol inks, and they’re safer for both the people working with them and the people wearing the finished garments.

6. Extremely Durable Prints

DTF prints hold up incredibly well through repeated washing and wearing without cracking, peeling, or fading. And when you run your fingers over the design, it feels smooth to the touch instead of heavy or rubbery, and the print stays sharp and vibrant far longer than traditional methods ever could.

We could keep adding to this list, things like how cost and energy-efficient this technology is, or how easy it is for both you and your team to learn it, and so on. But we’ll circle back to these advantages as we move through the rest of the article.

For now, let’s take a look at ColDesi’s lineup of DTF printers.

Because, after all, isn’t this why you’re really here? To find the printer that actually delivers on everything you just read about.

Introducing ColDesi’s Complete Lineup of DTF Printers

Our range includes five DTF printers, plus a hybrid UV/DTF model that combines the strengths of ultraviolet and direct-to-film printing.

These are all the DTF printers currently available in ColDesi’s lineup, giving you a wide selection to help you choose the right machine for your business.

Each printer comes equipped with the full set of features we’ve already covered, along with additional capabilities depending on the model.

With that foundation in place, we can take a closer look at each model to understand what makes it unique, what it does best, the workload it can handle, and the setups it is best suited for.

When you compare the printers, your decision will usually come down to four main factors: your budget, the space you have available, the print width you need, and the level of output your business requires.

With that, let’s talk about printers themselves.

ColDesi DTF 12H2 – A fast, compact direct-to-film (DTF) printer with a 12″ wide print field designed for small businesses and entry-level users.

It can print around 50 transfers per hour at 8”x10” size.

We’re talking full-color prints that adhere to almost any garment and have just a 10 second initial press time.

And the best part? it’s small enough for a desk and slim enough to fit through a standard doorway.

The 12H2 is available in four configurations, each offering different features, add-ons, and price points.

ColDesi DTF 24H2 – A direct-to-film (DTF) printer with a 24-inch-wide print field and a dual-head system that delivers higher resolution and faster throughput than the compact 12H2.

Capable of printing up to 45–55 linear feet per hour, or approximately 100 full-size (8″ × 10″) transfers.

The unit includes an integrated fume extractor, so there’s no need for an external system. Fully assembled, the printer comes in at 562 lbs.

ColDesi DTF 30H2 – The DTF 30H2 expands the print area to 30 inches and maintains a dual-head configuration.

It can do up to about 43 linear feet an hour. That’s roughly 180 full-size 8×10 transfers at an impressive 720 × 1800 DPI.

This makes it ideal for larger production runs or wide-format jobs like jackets, hoodies, banners, and more.

You can print multiple designs at the same time, which really cuts down on setup. Plus, it works on all kinds of materials—cotton, polyester, leather, even wood.

With 1000 ml ink bags, you can print longer without stopping for a refill, a little convenience that makes your day run smoother.

ColDesi DTF 24H5 – A direct-to-film (DTF) printer with a 24-inch-wide print field and a five-head system that delivers maximum throughput and high-resolution output.

Capable of printing up to 158 linear feet per hour, or approximately 400 full-size (8″ × 10″) transfers, it’s ideal for high-volume production and businesses needing fast, large-scale printing.

The 24H5 offers more than standard CMYK output—it features an Expanded Color Gamut option with CMYKOG + White (Cyan, Magenta, Yellow, Black, Orange, Green). This extended color range produces richer saturation, smoother gradients, and enhanced tonal depth.

It’s ideal for applications demanding high visual fidelity, such as photographic imagery, brand-critical logos, and intricate multi-color artwork.

ColDesi DTF 24H5E – A newer, upgraded version of the original 24H5. It keeps everything people already like about the line but adds a few thoughtful upgrades that make day-to-day production a lot smoother.

Namely, this model includes an Extended Dryer System, an Advanced Pre-Heating Chamber, and an automated wet-capping system for enhanced printer reliability and more consistent output.

Featuring a 24-inch print width and five advanced Epson i3200 print heads, the 24H5E delivers outstanding speed, precision, and reliability for high-volume production environments. In real numbers, it produces 500+ transfers per hour and over 275 linear feet of printed film.

Similarly, the 24H5 offers more than standard CMYK output—it features an Expanded Color Gamut option with CMYKOG + White (Cyan, Magenta, Yellow, Black, Orange, Green).

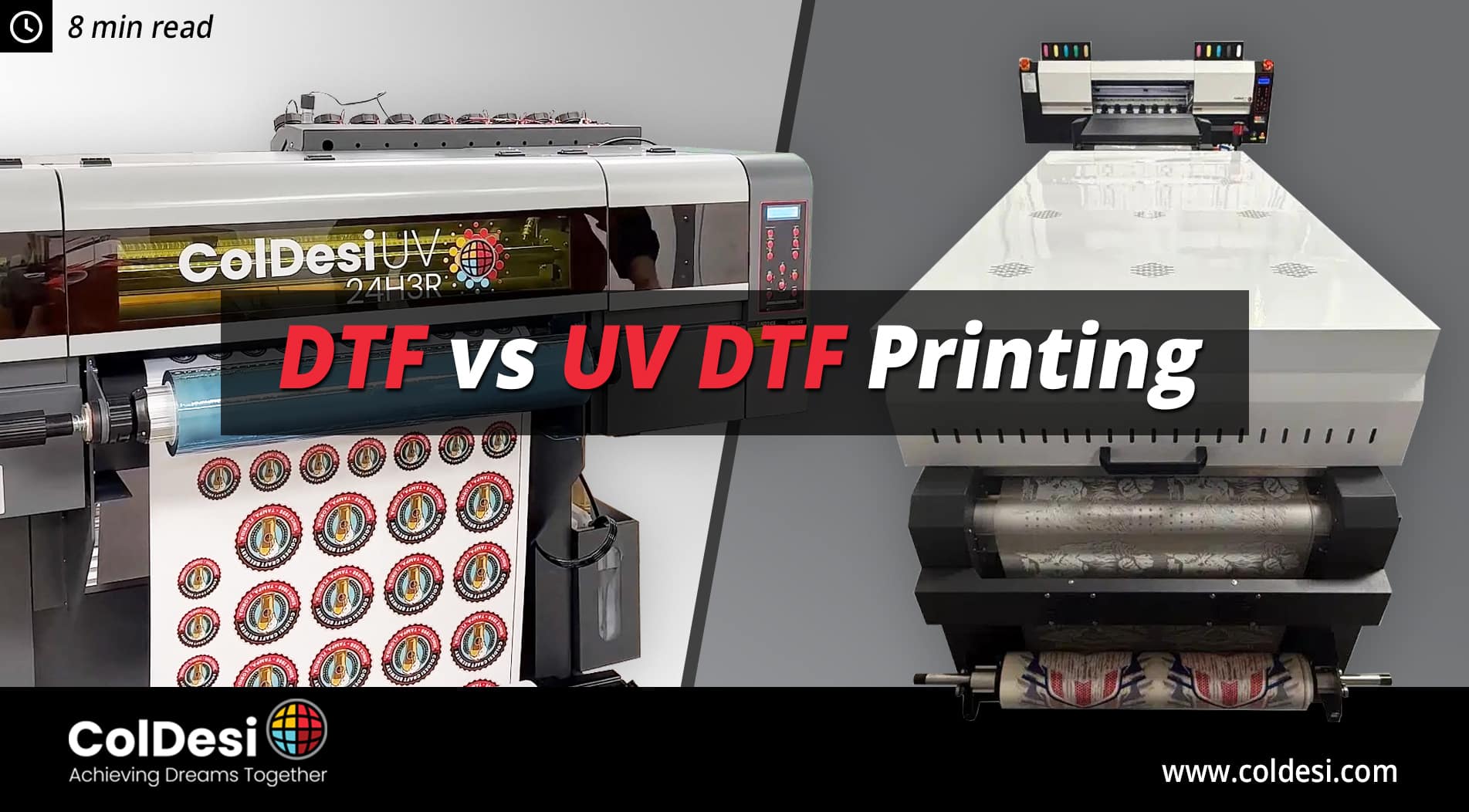

ColDesi UV 24H3R (UV DTF Printer) – As an added bonus, we want to highlight one of our hybrid printers: the ColDesi 24H3R UV/DTF printer. While it’s not exactly a 1:1 DTF printer, it carries that technology in its DNA. This multi-purpose printer combines the strengths of both UV (ultraviolet) and DTF (direct-to-film) printing.

Transfers produced with this system can be applied to a wide variety of hard surfaces, including flat or uneven areas, cylindrical or conical shapes, arcs, concave surfaces, and other irregular forms.

The printer is a roll-fed UV DTF system designed for creating durable, full-color decals and adhesive transfers on materials such as plastic, glass, metal, wood, and ceramic. It is built for high-speed production, allowing businesses to efficiently customize items like tumblers, awards, and equipment. The process is handled all in one go, eliminating the need for separate steps such as weeding or lamination.

If any of these printers caught your eye, you may want to bookmark their product pages so you can easily return to them later when weighing your options.

When you’ve narrowed down your choice, remember that you can request a demo or talk with one of our product specialists to get all your questions answered.

But we’re not done yet, there’s still more to talk about.

Next, let’s take a look at the numbers and metrics that matter most, the ones that show what these printers can truly do for your business.

The ROI of DTF

So… what’s the return?

Short answer: more profit per job. Long answer: the rest of this chapter.

With DTF, the numbers start working in your favor the moment you move even a small percentage of your work away from traditional methods.

ROI doesn’t come from one big dramatic efficiency gain—it comes from a stack of small, measurable improvements across the board.

Add them up, and you get a decoration method that simply makes you more money with less work.

And honestly, this is the part that’s often easier to show than to explain.

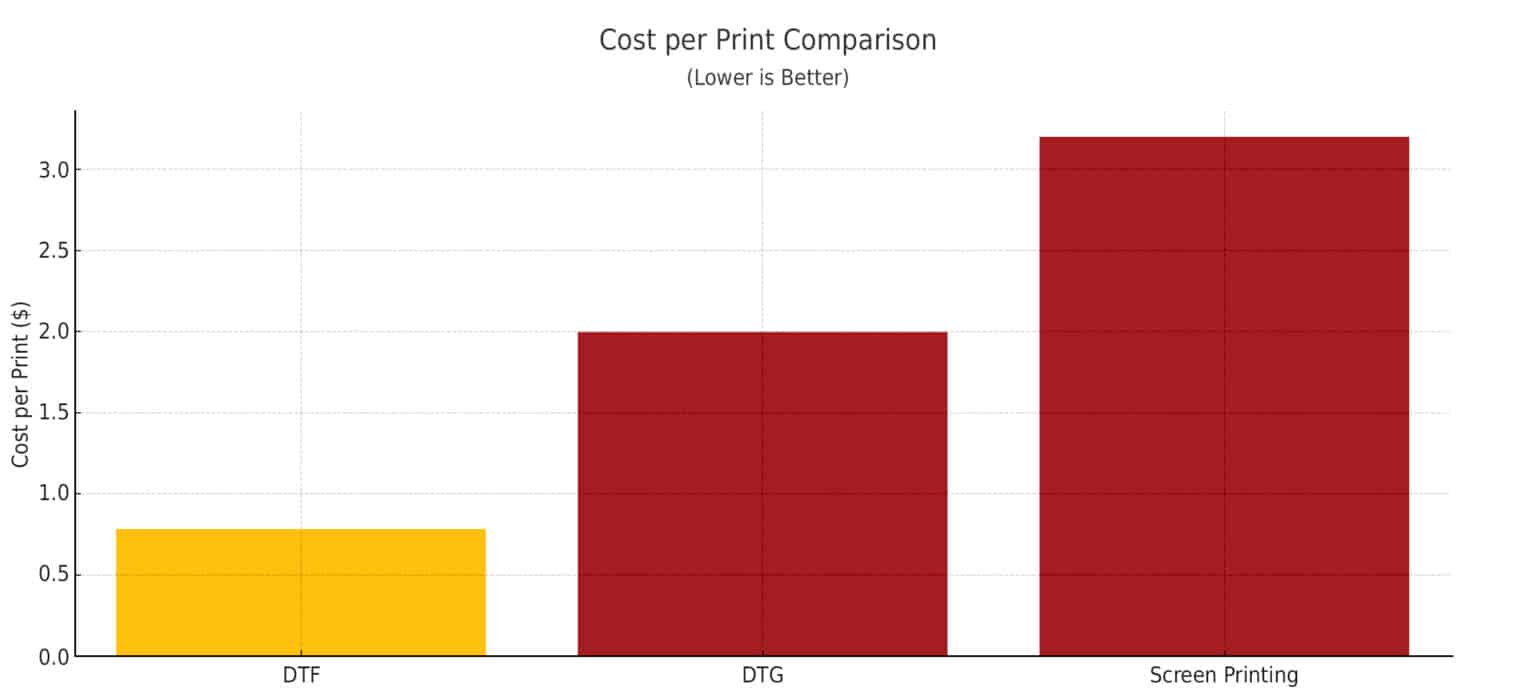

What follows are comparison charts between DTF and the traditional printing methods shops have been using for years. So you can clearly see just how much better DTF really is.

What this tells us is simple: DTF is way cheaper per print.

The chart makes it obvious, DTF comes in well under one dollar, while DTG is roughly twice as high, and screen printing is higher still.

When your cost per print drops this much, you’re not just saving pennies, you’re increasing your margin on every single order.

A dollar saved here and there might look like a small win on paper, but it adds up quickly.

Over the course of a full week of production, it becomes a shockingly large number.

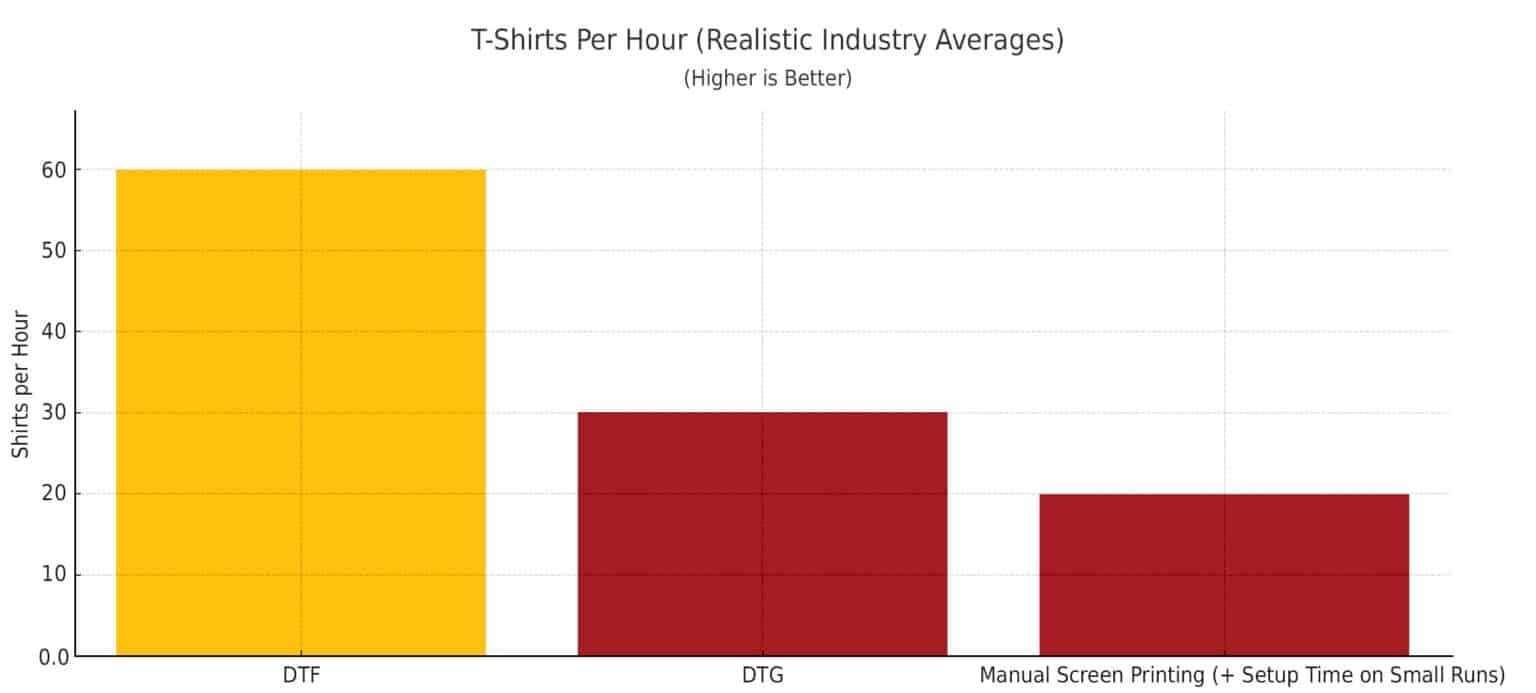

What this chart tells us is pretty straightforward: DTF does not just earn you more per shirt because it costs less to produce. It also lets you produce significantly more shirts in the same amount of time.

DTF averages around 60 shirts per hour, which is roughly double what most DTG setups can manage on a good day.

Screen printing falls even further behind once you factor in all the manual setup, cleanup, and those little stop-and-go moments that slow the process down.

When those slowdowns happen repeatedly throughout the day, they end up eating huge chunks of your schedule.

With DTF, you avoid most of that, which means you stay in a steady, productive rhythm from one job to the next.

So, when you combine lower costs per print with higher output, you get the compounding effect that really drives DTF’s ROI. And if you’ve ever felt like your shop was working harder than the numbers show, these charts might finally explain why.