Selecting the right equipment is critical for businesses aiming to expand their operations. Among the options available, sheet-fed DTF printing and roll-to-roll systems are the most common. Both have advantages and limitations, so it is important to understand their differences to make an informed choice.

Overview and Limitations of Sheet-Fed DTF Printing

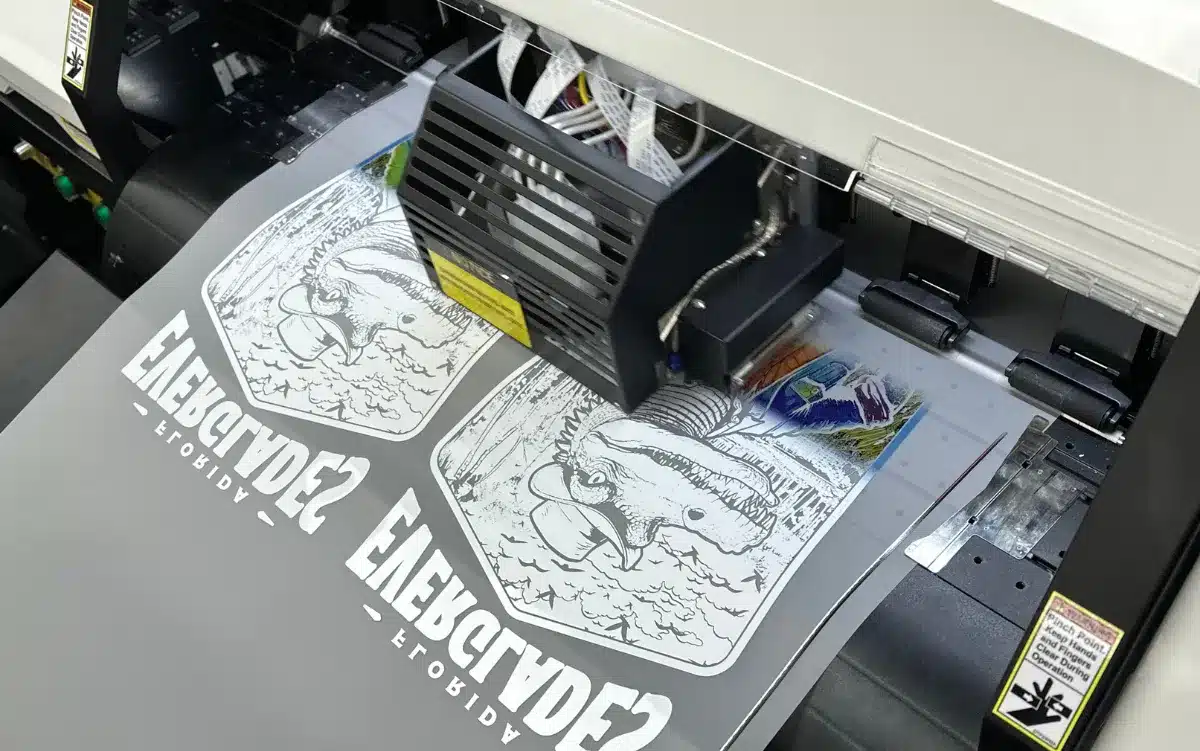

Sheet-fed DTF printing operates similarly to a traditional inkjet printer. Pre-cut sheets of film are fed into the printer, and designs are printed onto the sheet using a combination of inks.

After printing, an adhesive powder is applied to the design. The curing process then sets the ink and activates the adhesive. The printed sheet is then heat-pressed onto the fabric to complete the transfer. Each step of this method is manual. Despite its accessibility and simplicity, sheet-fed DTF printing has several limitations:

- Production Bottlenecks: Manual feeding and handling at each stage of the process create inefficiencies, particularly in high-volume production environments.

- Higher Labor Costs: The manual nature of sheet-fed systems increases labor demands. Operators must manage every stage of the process, from film feeding to curing.

- Inconsistent Results: Human intervention at each step can cause alignment issues, inconsistent adhesive application, and variations in print quality, which may compromise customer satisfaction.

- Limited Scalability: Sheet-fed printers struggle to meet the demands of growing businesses due to their slower production rates and labor-intensive operation.

The Advantages of Roll-to-Roll DTF Printing

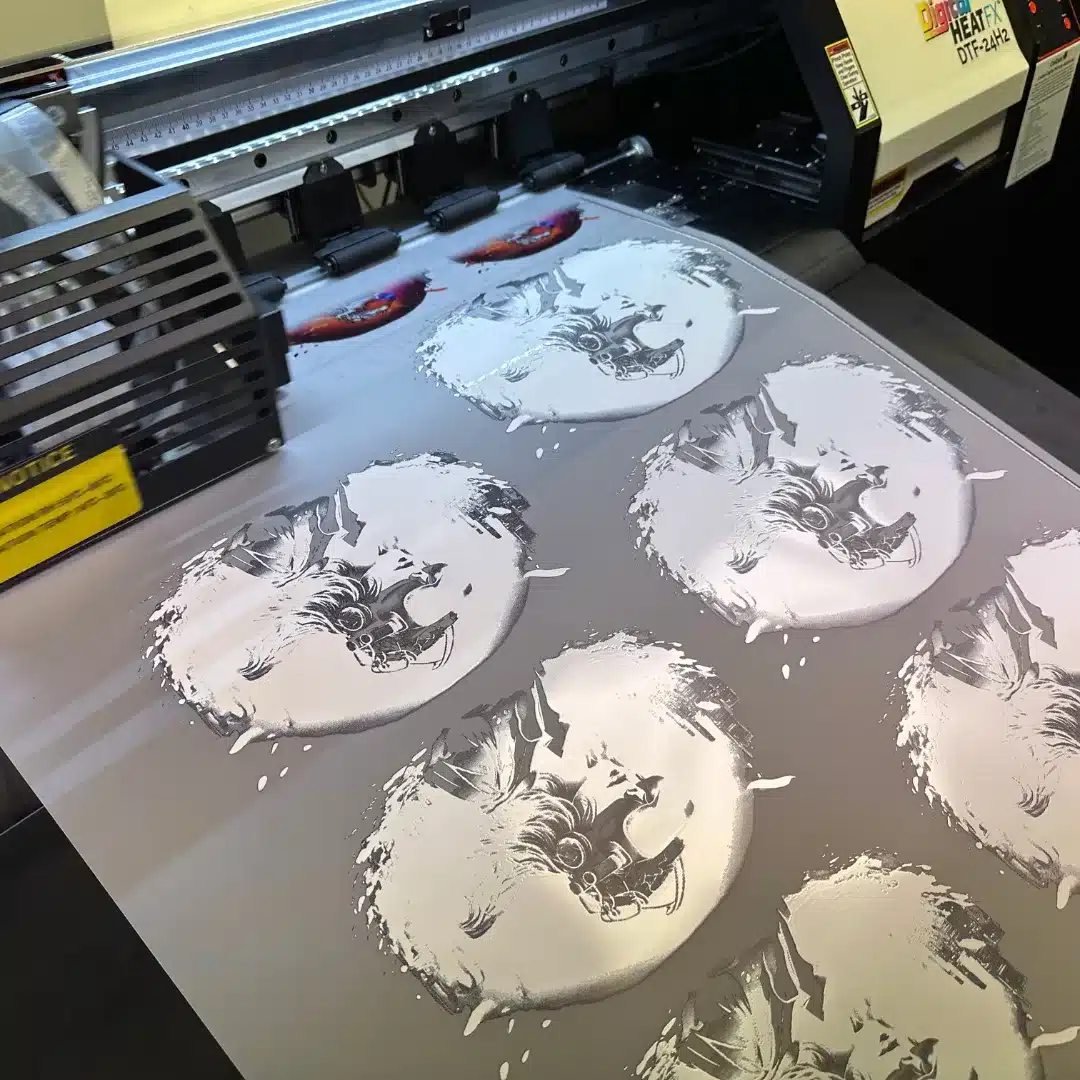

Roll-to-roll printing eliminates the inefficiencies of sheet-fed systems by automating the production process. By using rolls of film instead of sheets, these printers streamline production and integrate printing, adhesive application, and curing into a seamless, uninterrupted workflow. This level of automation delivers several key advantages:

Automation and Efficiency

Roll-to-roll systems streamline the entire DTF process with minimal operator intervention, enabling continuous production with increased efficiency.

High-Volume Capabilities

Designed for scalability, roll-to-roll printers support large production runs, allowing businesses to meet high demand without compromising quality or speed.

Reduced Labor Costs

Automation significantly lowers labor requirements, as a single operator can manage multiple machines, reducing staffing costs while boosting productivity.

Enhanced Consistency

Automated systems ensure precise alignment, uniform adhesive application, and consistent curing temperatures, resulting in reliable, high-quality prints across all production volumes.

Ink Flow & Consistency

Roll-to-roll printers often have better ink delivery systems, maintaining consistent print quality over long runs.

Environmental Control

Some roll-to-roll models include additional features, such as better temperature and humidity control, to enhance ink performance and adhesion.

Alignment & Registration

Roll-to-roll automation reduces the risk of misalignment, which can sometimes affect the final print quality in manual sheet-fed systems.

Adaptability and Scalability

Roll-to-roll printers are suitable for both small and large-scale orders. Their versatility allows businesses to adapt to changing needs seamlessly.

Comparative Analysis: Sheet-Fed vs. Roll-to-Roll DTF Printing

|

Feature

|

Sheet-Fed DTF

|

Roll-to-Roll DTF

|

|---|---|---|

|

Automation |

Manual |

Fully Automated |

|

Production Speed |

Slower |

High-Speed |

|

Labor Requirements |

High |

Low |

|

Print Consistency |

Variable |

Consistent |

|

Scalability |

Limited |

Scalable |

|

Cost Efficiency |

Higher Costs for Large Volumes |

Lower Costs Per Unit for High Volumes |

|

Best For |

Small-Scale Or Niche Production |

High-Volume, Scalable Production |

Why Custom Apparel Businesses Choose Roll-to-Roll DTF Printing

For custom apparel businesses, roll-to-roll DTF provides operational efficiency and scalability. Key benefits include:

- Streamlined Operations: Automation reduces the complexity of production and frees up resources for other business functions.

- Faster Turnaround: Continuous production enables businesses to meet tight deadlines and manage last-minute orders effectively.

- Cost Reduction: Lower labor costs, reduced material waste, and efficient processes enhance profit margins.

- Improved Customer Satisfaction: Consistent, high-quality prints increase customer loyalty and repeat business.

- Future-Ready Technology: Roll-to-roll printers are designed for scalability, offering long-term value as businesses expand.

The Long-Term Value of Roll-to-Roll DTF Printing

For businesses looking to enhance profitability, roll-to-roll printing is the better method. It eliminates the inefficiencies of sheet-fed systems and provides scalability, consistency, and operational efficiency.

Roll-to-roll DTF printers require a higher initial investment than sheet-fed systems, but they offer advanced automation, durability, and high-production capabilities.

Unlike sheet-fed printers, roll-to-roll models automate feeding, printing, adhesive application, and curing. This seamless workflow relies on high-quality components like motorized rollers, tension control systems, and sensors, adding to the overall cost.

Roll-to-roll printers also have a more robust build, designed for high-volume production and long-term use. Strong frames, industrial-grade parts, and cooling systems improve durability, allowing continuous printing with fewer interruptions. The ability to scale production makes roll-to-roll printers a long-term investment.

Built-in curing units and automatic adhesive powder applicators increase efficiency. Unlike sheet-fed systems, roll-to-roll printers manage these processes automatically, reducing labor costs while maintaining consistent results. These additional components also raise the upfront price.

Print head technology and ink delivery systems also impact cost. Both systems may use similar print heads, but roll-to-roll printers optimize ink flow for uninterrupted production. Many models feature bulk ink delivery systems. These larger reservoirs and circulation mechanisms help maintain efficiency during long runs.

Roll-to-roll printers support large production volumes by maintaining speed and quality while reducing material waste and labor costs. This scalability makes them ideal for growing businesses.

Many roll-to-roll systems include specialized software. Features like batch processing, print queuing, and ink management improve workflow by boosting productivity but add to the overall investment.

Sheet-fed printers have a lower entry cost, but roll-to-roll DTF printers provide better efficiency, consistency, and scalability. The higher initial investment pays off in the long run. Businesses looking to expand will benefit from roll-to-roll technology.

Upgrade Your DTF Printing for Maximum Efficiency

Ready to take your production to the next level? Explore roll-to-roll DTF printing and invest in a solution that grows with your business. Visit our website, live chat with a Pro, or call 877-793-3278 to learn more.