A Real-World Case Study (8” x 8” Front Print, 250 Units)

“Costs updated November 2025 based on average U.S. shop data, ColDesi printers, ink/film, and real customer benchmarks. Your exact DTF vs. Screen Printing costs may vary by supplier, region, and efficiency.”

Imagine this: A customer walks in (or emails) with a killer 4-color, full-detailed design and wants 250 shirts… by next week.

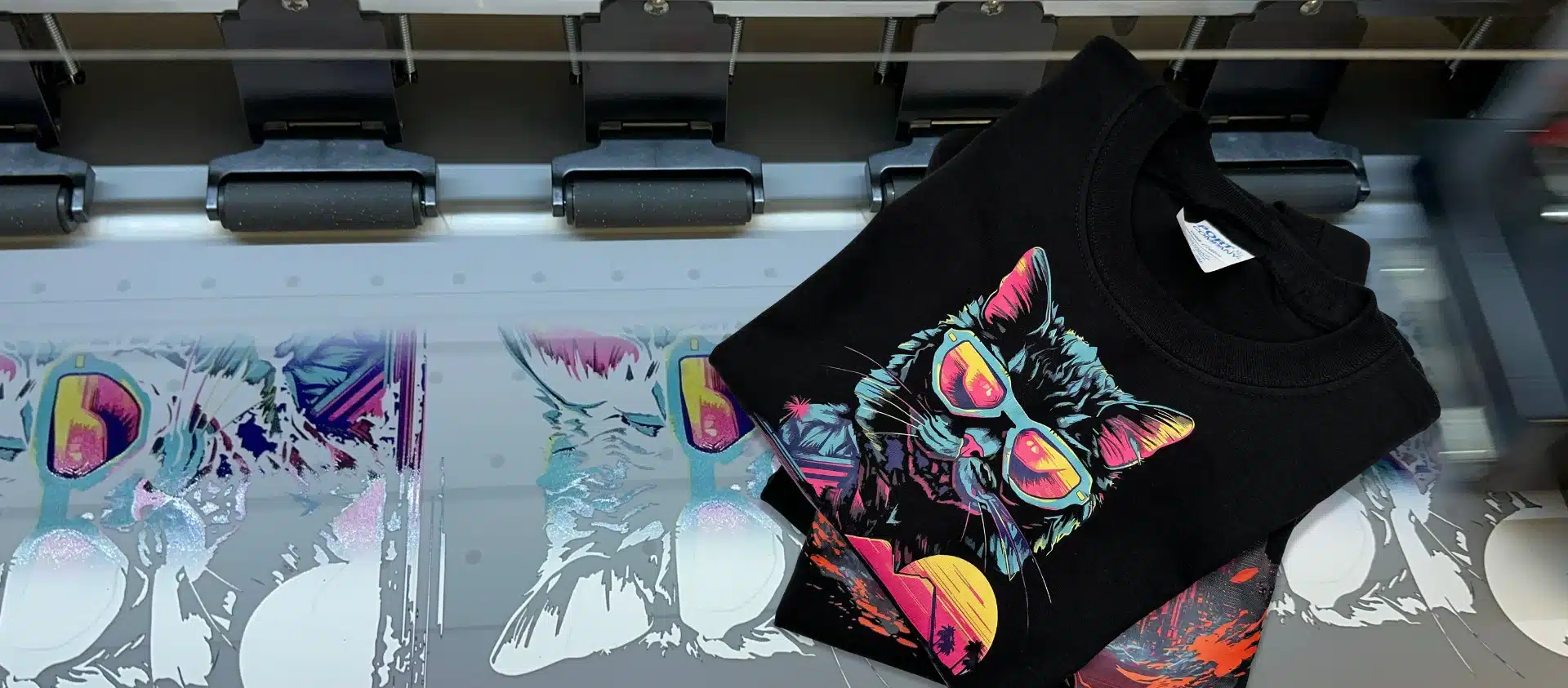

Do you fire up the manual press, burn screens, and block out 7+ hours of production — or do you hit “print” on your DTF system and have the transfers rolling in under 30 minutes, with finished shirts flying out the door in less than 4 hours total?

For years, the answer was “it depends” — loaded with vague rules of thumb, outdated numbers, and a lot of guessing.

Not anymore.

We took a standard 8×8″ front-print job (250 cotton tees, single-operator shop, $250k–$750k revenue range) and ran the exact numbers side-by-side in November 2025 — using today’s actual consumable prices, current ink/film costs, and real production speeds from one of the most popular DTF brands on the market (yes, we’re talking about our ColDesi 24H5E).

Counting the Costs Accurately, Calculate for Your Situation.

This case study is designed to work on a real-world project, using numbers that should accurately represent the costs of a t-shirt customization business using DTF or Screen Printing.

And further, give you the power to alter the numbers and calculate specific costs based on your exact job scenarios using our DTF vs Screen Printing Calculator.

Each business is unique with different labor costs, print speeds, and general material costs. This calculator and case study will allow business owners the ability to study and determine workflows for their business and future equipment investment opportunities.

Screen Printing vs. DTF in 2025:

Which Actually Makes You More Money on a 250-Shirt Order?

(A Real-World Cost Battle + Free Interactive Calculator)

Screen Printing vs DTF Cost Calculator

Compare total cost, cost per shirt, and labor time for a single 8×8 print job.