The ColDesi 24H5 DTF Printer is engineered for serious production environments and features a powerful five Epson i3200 printhead setup. Each printhead is dedicated to specific functions across ink channels, maximizing both print speed and quality.

The optimized printhead arrangement ensures detailed image reproduction, accurate ink layering, and consistent white underbase application. This results in sharp edges, smooth gradients, and vibrant color. It bridges the gap between traditional screen printing and modern digital methods, delivering durable, full-color transfers with commercial-grade consistency.

The 24H5 DTF Printer features five dedicated printheads that deliver precise printing and minimize color bleeding and misalignment. Balanced ink flow and tight color control ensure crisp, high-resolution results. Spreading the workload across heads also extends printhead life and reduces maintenance downtime.

The ColDesi 24H5 delivers the performance, speed, and reliability that businesses demand. It’s a great choice for operations that need professional-grade output without compromising on quality or efficiency.

Ink Configuration Options: Standard and Expanded Color Gamuts

The ColDesi 24H5 DTF Printer features two print configurations to match different business goals and visual needs. Choose between CMYK+W or CMYK+OG+W to tailor the printer to your production. This flexibility boosts color quality, enhances efficiency, and increases ROI. Both options feature five printheads but differ in their allocation across ink channels.

Standard Gamut Configuration: CMYK + White

The ColDesi 24H5’s standard CMYK + W option utilizes three printheads for cyan, magenta, yellow, and black inks, while allocating two printheads exclusively for white ink. This configuration is optimized for high-volume production environments where speed is prioritized.

Key Advantages:

- Up to nine percent faster than the expanded gamut configuration

- Consistent white ink coverage across full production runs

- Ideal for operations requiring maximum efficiency and fast turnaround

Expanded Gamut Configuration: CMYKOG + White

The expanded CMYKOG + W configuration is tailored for applications requiring broader color reproduction and superior visual accuracy. Two printheads are designated for CMYK inks, two for white ink, and one for orange and green inks. This arrangement expands the printer’s available color gamut by up to 20% over the standard gamut. It provides enhanced capabilities for nuanced color transitions, brand-specific hues, and complex artwork.

Key Advantages:

- Exceptional vibrancy in mid-tones, oranges, and greens

- Enhanced capability for photorealistic prints and corporate color matching

- Enables consistent reproduction of challenging color gradients

ECO PASSPORT Certified Inks

ColDesi’s DTF inks are certified under the OEKO-TEX® ECO PASSPORT standard, confirming compliance with global environmental and safety criteria. These water-based pigment inks are formulated to be free of harmful substances, safe for use in skin-contact applications, including children’s garments.

Environmental Credentials:

- Non-toxic and compliant with stringent safety regulations

- Approved for sensitive markets, including schools and healthcare

- Adds value to products in eco-conscious consumer segments

This certification enhances the marketability of printed garments.

Print Optimizer Software

The 24H5 DTF Printer features ColDesi’s proprietary DTF Print Optimizer Software. This is a powerful tool designed to give production teams complete control over their output. Operators can fine-tune print parameters to match various designs, substrates, and production goals. It provides independent control of ink laydown by channel, as well as gradient optimization for smoother color transitions. The ink-saving modes are ideal for black-and-white or monochrome graphics. The software includes preset configurations tailored to different fabric types and design styles, allowing users to switch between jobs with optimal results. Print Optimizer Software enhances both efficiency and print excellence on every run.

Automated Wet Capping System

The 24H5 DTF Printer features an automated wet capping system designed to reduce downtime and prolong the life of the printheads. This technology seals and hydrates the nozzles during non-operational periods. This reduces the risk of clogs and ink drying.

Operational Benefits:

- Automated printhead protection during idle times

- Reduced manual maintenance requirements

- Lower ink consumption due to minimized waste

- Improved print consistency and long-term reliability

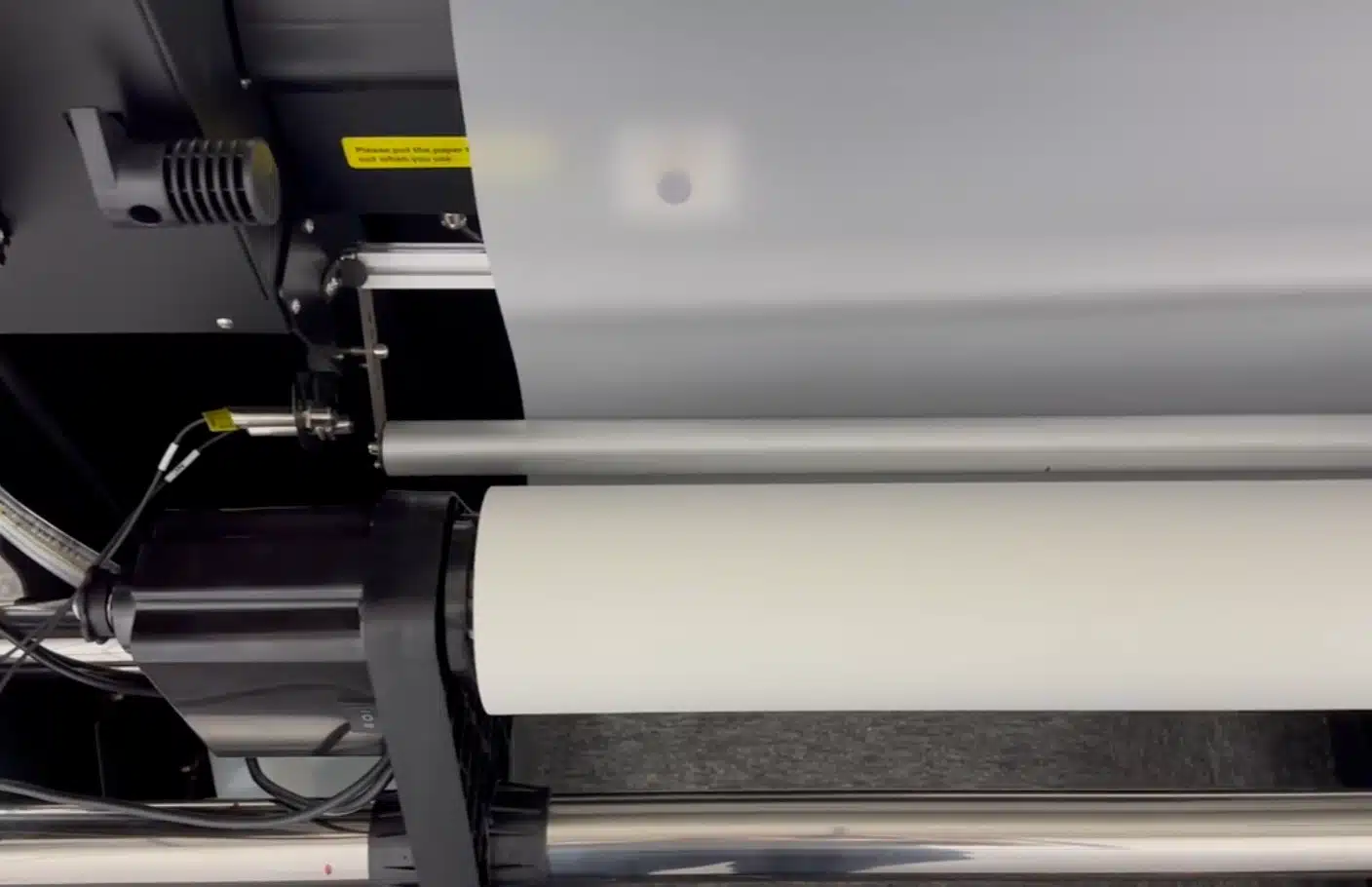

Automatic Media Tension Control

The 24H5 DTF Printer features a motorized dancer bar that provides automated media tension control, ensuring smooth and accurate film handling throughout production. Equipped with real-time sensors, the system continuously regulates film tension. This prevents media slack or overstretching. It helps to maintain a uniform feed that eliminates distortions, ensuring more reliable alignment throughout extended production runs. It also eliminates the need for manual adjustments and re-calibrations. This minimizes material waste, reduces the risk of print misregistration, and helps preserve design accuracy for consistently high-quality output.

High-Efficiency POWR Shaker/Dryer System

The ColDesi 24H5 DTF Printer features the advanced POWR Shaker/Dryer, which automates the adhesive powder application and curing process. This shaker/dryer unit ensures precise and even powder distribution while delivering fast, consistent drying to produce transfers ready for immediate use.

Integrated Process Benefits:

- Enhanced bonding strength between ink and adhesive

- Uniform powder coverage across the film

- Streamlined transfer prep with minimal manual labor

- Rapid drying for efficient production flow

Built-In Fume Extraction System

The integrated fume extraction system in the shaker/dryer boosts air quality by capturing airborne particles and odors produced during operation. This built-in feature eliminates the need for a separate ventilation unit. It also removes the extra expenses of purchasing and shipping an external unit. This helps to simplify setup and minimize total cost of ownership.

Workplace Advantages:

- Cleaner, safer operating environment

- Compact footprint with no need for bulky auxiliary equipment

- Reduced purchase cost, setup complexity, and installation time

This built-in filtration system makes the 24H5 an ideal choice for confined workspaces, as well as businesses trying to maintain OSHA-compliant air quality standards, all without the hassle and added expense of external air handling systems.

ColDesi 24H5 DTF Printer Features and Benefits

|

Feature

|

Description

|

Benefit

|

|---|---|---|

|

5 Epson i3200 Printheads |

Advanced configuration |

Maximized output precision |

|

Standard Color Gamut |

3 heads for CMYK, 2 for White |

High-volume productivity |

|

Expanded Color Gamut |

CMYK + Orange/Green + White |

Superior color fidelity |

|

ECO PASSPORT Inks |

OEKO-TEX® certified |

Safe and marketable output |

|

Print Optimizer Software |

Custom print parameter control |

Efficiency and precision |

|

Automated Wet Capping |

Seals heads during idle time |

Reduced clogging and downtime |

|

Automatic Tension Control |

Motorized media management |

Accurate film alignment |

|

POWR Shaker/Dryer |

Adhesive + Curing automation |

Seamless transfer preparation |

|

Built-In Fume Extraction |

Air filtration system |

Cleaner, safer workplace |

Strategic Investment for Growth-Focused Print Businesses

The ColDesi 24H5 combines industrial-grade reliability with advanced color management. This printer is ideal for high-volume production and premium-quality output. It offers both speed-optimized and color-enhanced ink configurations. This allows businesses to scale efficiently while meeting the demands of their clients.

Request a Demonstration or Consultation

To see how the ColDesi 24H5 DTF Printer fits your production goals, schedule a demonstration or connect with a ColDesi specialist. Gain firsthand insight into its capabilities, configuration options, and integration process