Here’s a short description of what a t-shirt transfer printer is and does. We’ll talk about each choice and what it’s like to own and use.

But you’ll find many of the pros and cons apply to ANY customization business or side hustle, not just custom tees.

Making Money in Custom Tees and Promo Products

Using a transfer printer is by far the most popular way to make custom t-shirts. And some of those ways to earn side income are more profitable than others. And more fun!

In general, you can make a t-shirt transfer for between $.50 and $3.50

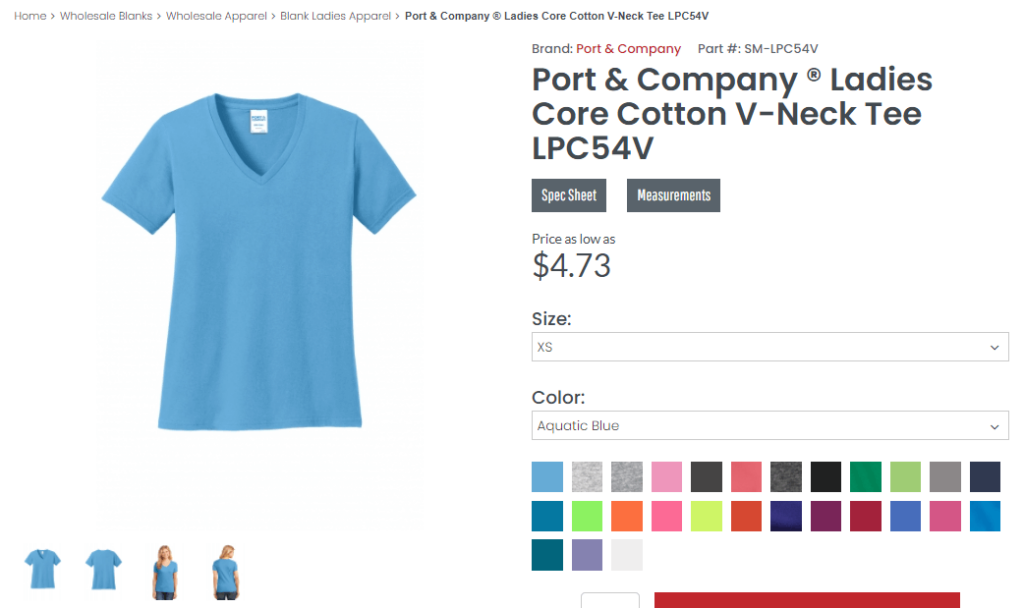

You can also purchase a high-quality wholesale blank t-shirt like the one below for under $5.00. There are definitely cheaper blank shirts out there, but we’ll use the following high-quality example for our purposes.

Regardless if you’re creating your own design or using a customer’s design, your cost for making a custom shirt with a transfer printer is somewhere between $5.50 and $8.50. It could end up lower or a little higher, but this is the most common range.

Custom designed t-shirts, on average, sell for $20.00-$25.00, according to a survey of custom t-shirt printers in the Custom Apparel Startups Facebook Group.

Just some simple math will show you that making $10.00-$15.00 per shirt is the norm.

Even just making 10 shirts per hour with a t-shirt transfer printer equals at least $100 in profit.

And $100/hour is a pretty good paycheck for a side hustle!

How does a t-shirt transfer printer work?

You can watch the example video below, but no matter what type of printer you’re using, you’ll do the following two steps:

2. Use a heat press to apply to a shirt

Which technology you decide to own determines everything in between.

The difference in OWNING one

All the videos, and this simple explanation we’ve given, make creating a custom t-shirt look very easy.

And it IS easy. But not necessarily always simple, if that makes sense.

These aren’t really “cons”; they’re just the more complex things that you’ll have to learn, get used to, and suffer through. No matter which one you choose:

- Graphics

This is critical because you will base a lot of decisions on what your customer will want. And different people want different things.If you’re not already a graphic designer but plan to create your own images, then you should think about this; If you bought Microsoft Word, does that make you a good writer? Or if you picked up a guitar for the first time, could you play it and make it sound great?

Would it be enough to get someone to PAY you to do those things? Maybe not.

Of course, clipart helps. And there are many places you can buy stock designs. But not every design is made to work well with every t-shirt printer technology.

A design company specializing in t-shirt designs, like, for example, http://coldesi-graphics.com can really help smooth the way for a startup here.

But whether you create them yourself OR have that done for you – be prepared for a learning curve.

- Blank Shirts

The right blank shirts or other garments can make ALL the difference. But most new custom t-shirt makers don’t think about that.

If you’ll notice, we used an excellent quality wholesale blank shirt in our profit example.

We could have used a $1 cheap shirt to make that look even better. But the cheaper shirts – or even just the WRONG shirt – will cost you way more money in the long run.

- Cheap shirts don’t wash well or last long

- Cheap shirts can twist in the wash

- Cheap shirts shrink in the dryer

- Cheap shirts fade fast, making your design look different

The wrong shirt can cause customer dissatisfaction, returns, lost time and money.

- Inventory Management

Managing your inventory is more about overpromising or underdelivering.

At some point, you’re going to run out of ink, toner, transfer paper, or some other supply item, just when you need them most.

Perhaps the shirt you usually use will be out of stock.

UPS or FedX will strike, or there will be a big weather event.

SOMETHING will happen that leaves your t-shirt making machine idle because you don’t have your supplies in stock.

You can protect yourself:

- Estimate your business and lay in supplies accordingly

- Have at least one or two backup blank shirt recommendations just in case

- Always quote a longer delivery time than you think you’ll need – you AND your customer will be happier.

White Toner Transfer Printers – Pros and Cons

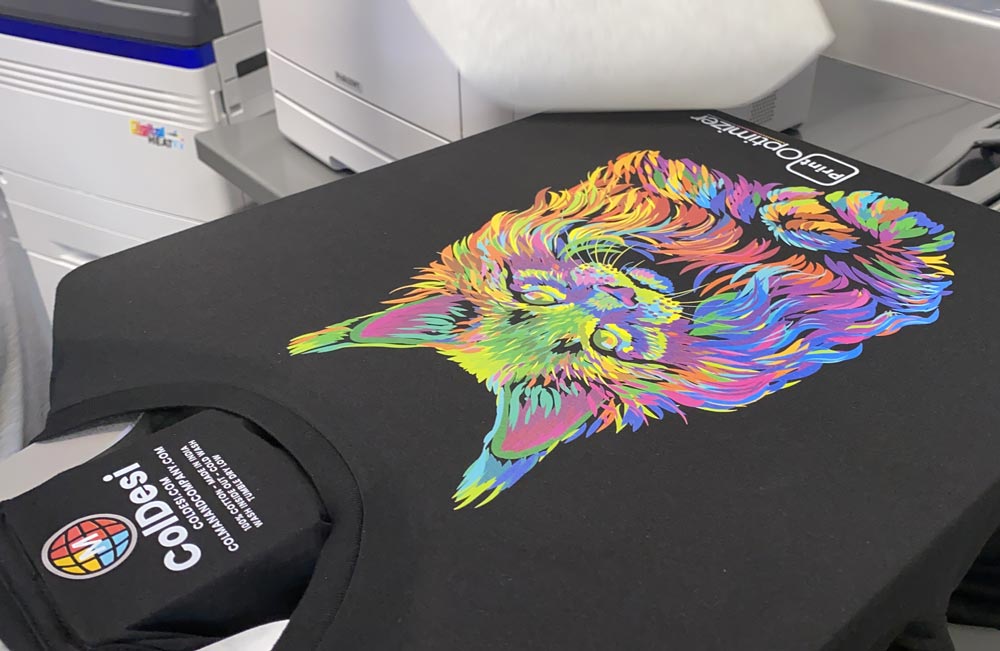

Here’s an example of using a white toner transfer printer to make a shirt.

White toner printers, like the DigitalHeat FX 8432 show here – which is based on the OKI pro8432WT – are probably the most versatile transfer printers.

The Pros:

- Big Designs often sell for higher prices. You can print on up to 13”x19” transfers

- Bigger transfers will fit MORE designs. Left chest logos are big business, and you can fit tons of them on a larger piece of transfer paper. That reduces cost and the time it takes to print.

- Apply white toner transfers to almost any shirt.

– Print onto polyesters and blends

– Color doesn’t matter – light and dark material is okay

- Make money selling WHOLESALE transfers

- No WEEDING, ever

The Cons:

- Transfer Paper will cost you more than other methods

- It takes a little longer if you’re using the AB paper – the “marrying process” is an extra step

- Upfront costs are a bit higher

- You don’t want to print just photos – your best results are with open designs

- You need to use a GREAT heat press. And that is pricey.

Sublimation Transfer Printers – Pros and Cons

Sublimation is probably the most popular transfer technology in the world. It’s a terrific choice for full-color transfers!

Here’s a video showing that process:

White toner printers, like the DigitalHeat FX 8432 show here – which is based on the OKI pro8432WT – are probably the most versatile transfer printers.

The Pros:

- VERY inexpensive to buy! You can get a Sawgrass Sublimation printer for as low as $599 – but even the 11” x 17” model is only $1,549

- Simple to use – there’s no 2 step process

- Supplies are inexpensive – a sheet of transfer paper costs under $.32

The Cons:

- There’s no white ink – so you can never sell a dark custom t-shirt. White is best.

- Only polyester or synthetic fabrics! 100% poly will give you the best, brightest image. Other blends are okay for a faded or vintage look.

- The BEST shirts to use – ones made for Sublimation like Vapor Apparel, can cost much more than a high-quality cotton tee. Here’s a great article on why you’ll want to use this premium brand.

Buying a T-Shirt Transfer Printer

The Sawgrass Sublimation printer and the DigitalHeat FX 8432 are 2 of the most popular t-shirt transfer printers, using the most popular technologies.

If you want to learn more about the others, here where to do that:

Direct to Film Printers

Read about them if you don’t mind a little more hands-on processes. This method requires the extra step of dusting a material onto the printed transfer. But the results are outstanding.

Roland BN-20

This is a printer-cutter, so it’s not often included in t-shirt transfer discussions, but it IS used to make them. Not the best feel to these, and you will have to weed depending on your design.

Bling Transfers

There’s a whole world of bling out there, and the ProSpangle, Spangle Elite, and CAMS machines are ways you can make transfers that sparkle.