Step 1. Unpackage the DTF Cure-Tray and Teflon Sheet. Make sure both objects are free and clear of any dust or debris.

Note: For the best results, the aluminum has been left unfinished and untreated. You may notice small imperfections on the surface of the tray, these should not affect the curing process.

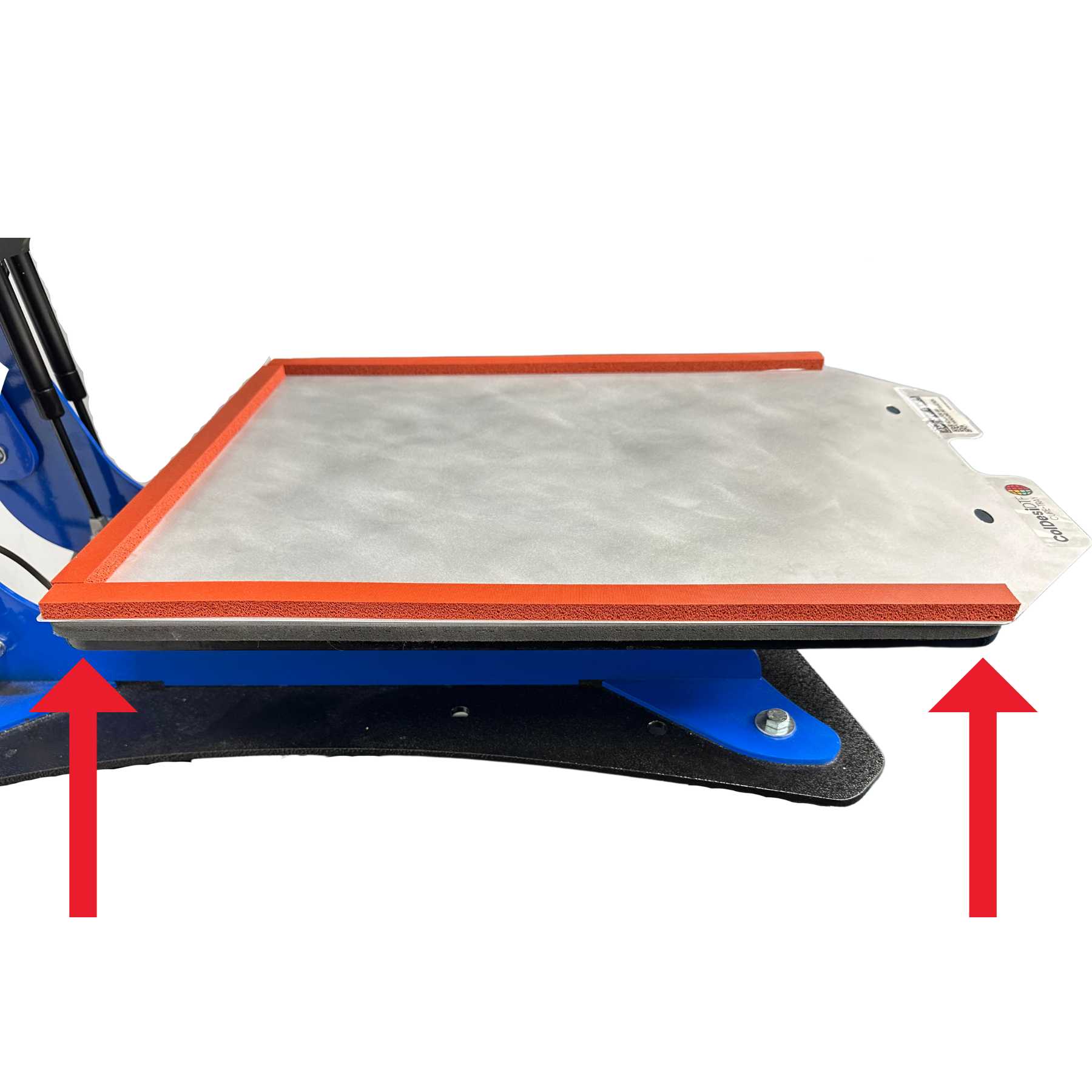

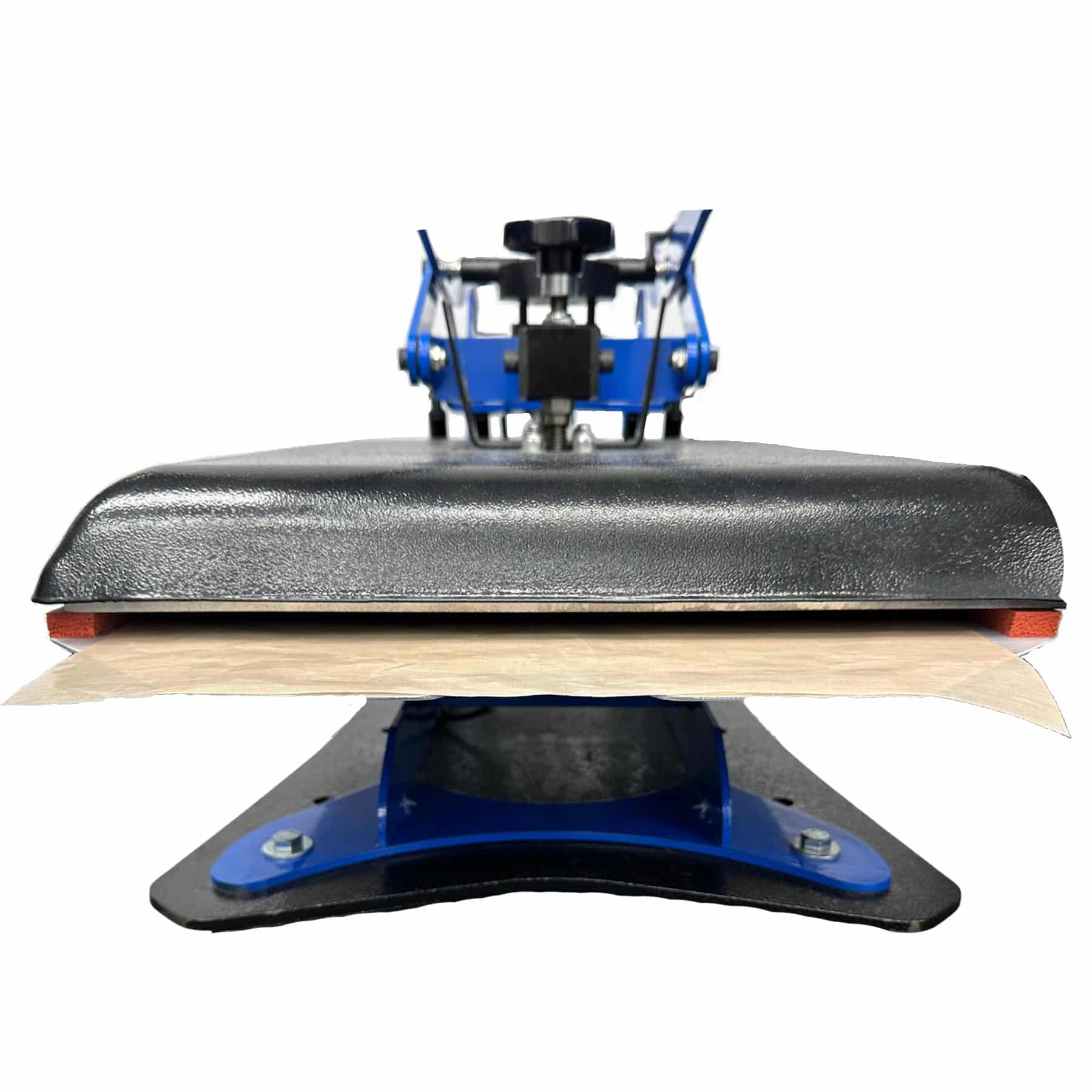

Step 2. Set the DTF Cure-Tray onto the heat press platen. Align the tray with the back corners of the platen, (the front edge of the tray will extend beyond the front portion of the heat press platen).

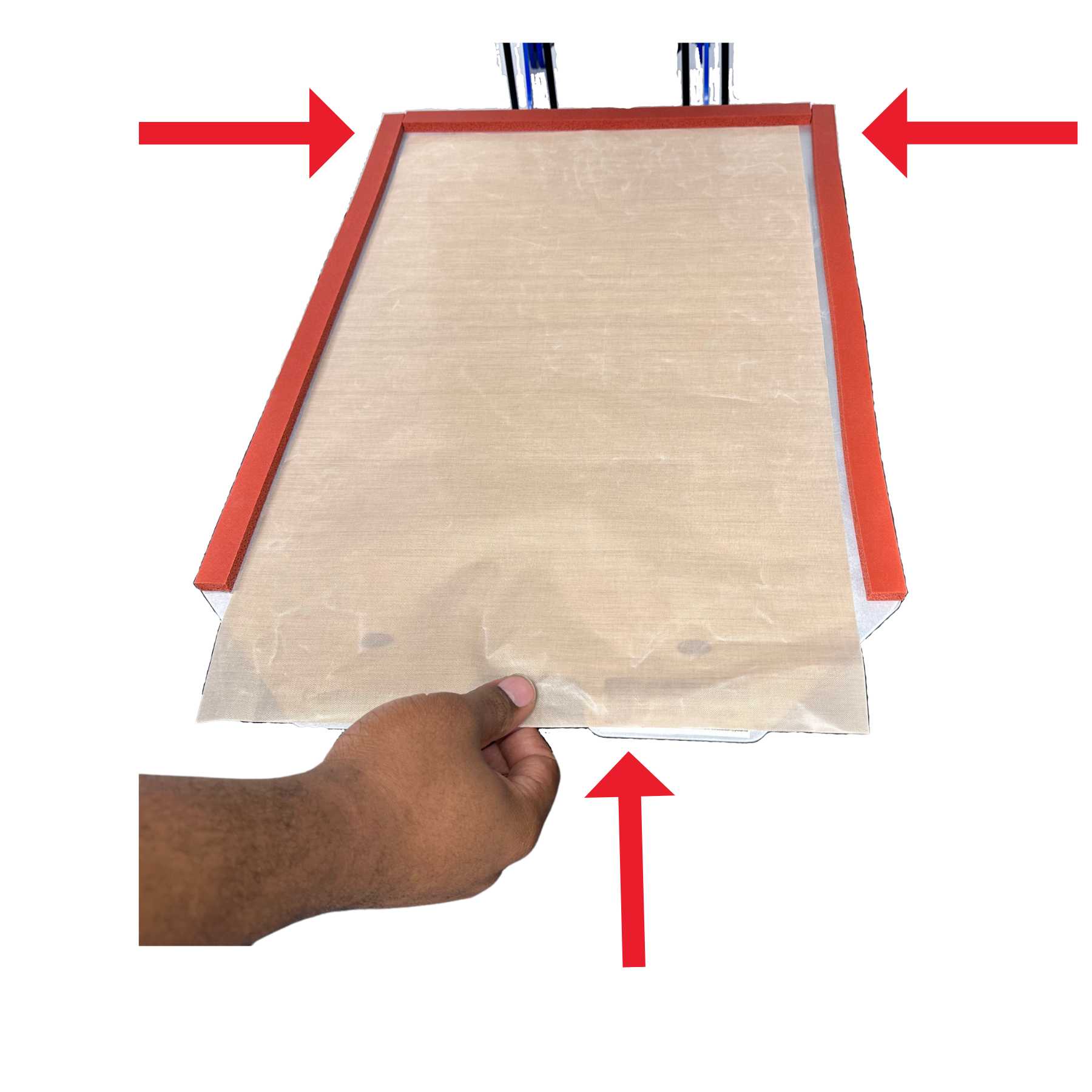

Step 3. Place the Teflon Sheet overtop the DTF Cure-Tray. The Teflon Sheet should fit inside the walled sides on the tray.

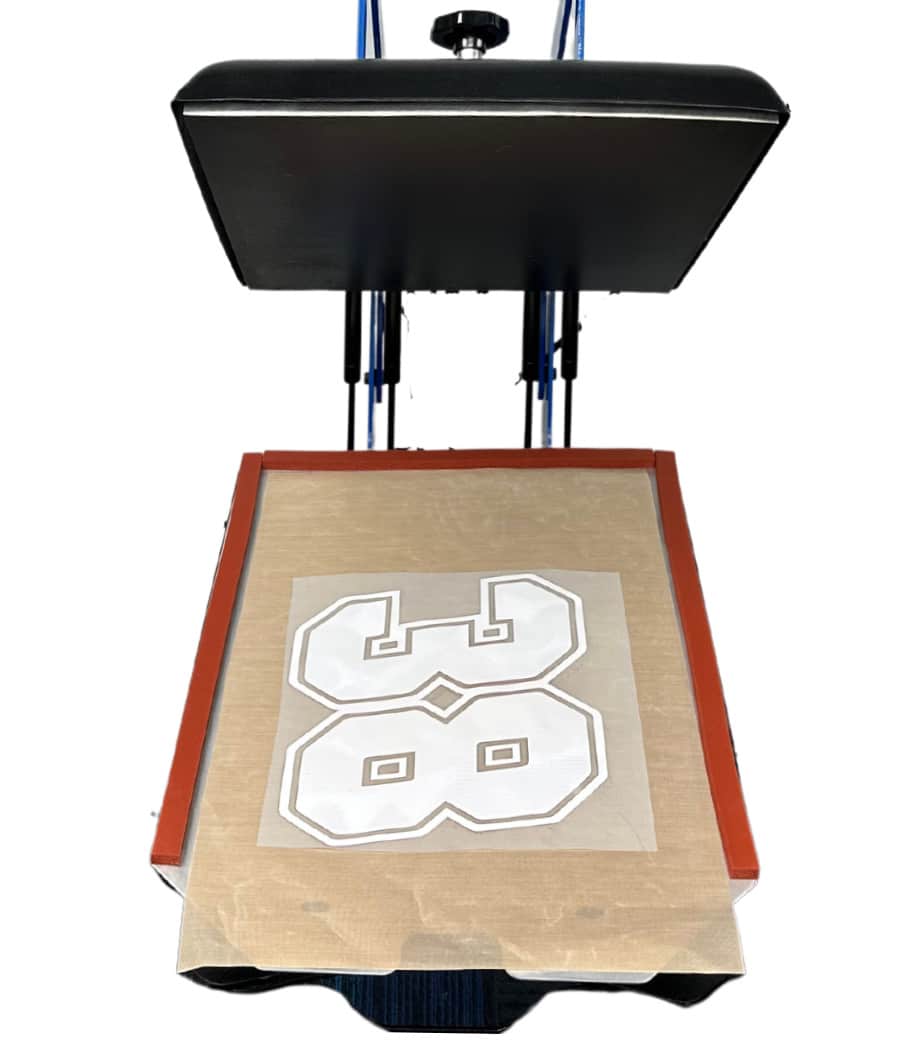

Step 4. Arrange the design transfer(s) on top of the Teflon Sheet. Close the press and heat the transfer(s) to the desired time and temperature. (Multiple transfers can be heated at once)

Note: To check the transfer, gently guide the Teflon Sheet from the DTF Cure Tray.

Step 5. Once the desired time and temperature have been met, simply remove the design transfer(s) from the heat press.

Note: Both the DTF Cure-Tray and the Teflon Sheet have been designed to remain on the heat press platen.

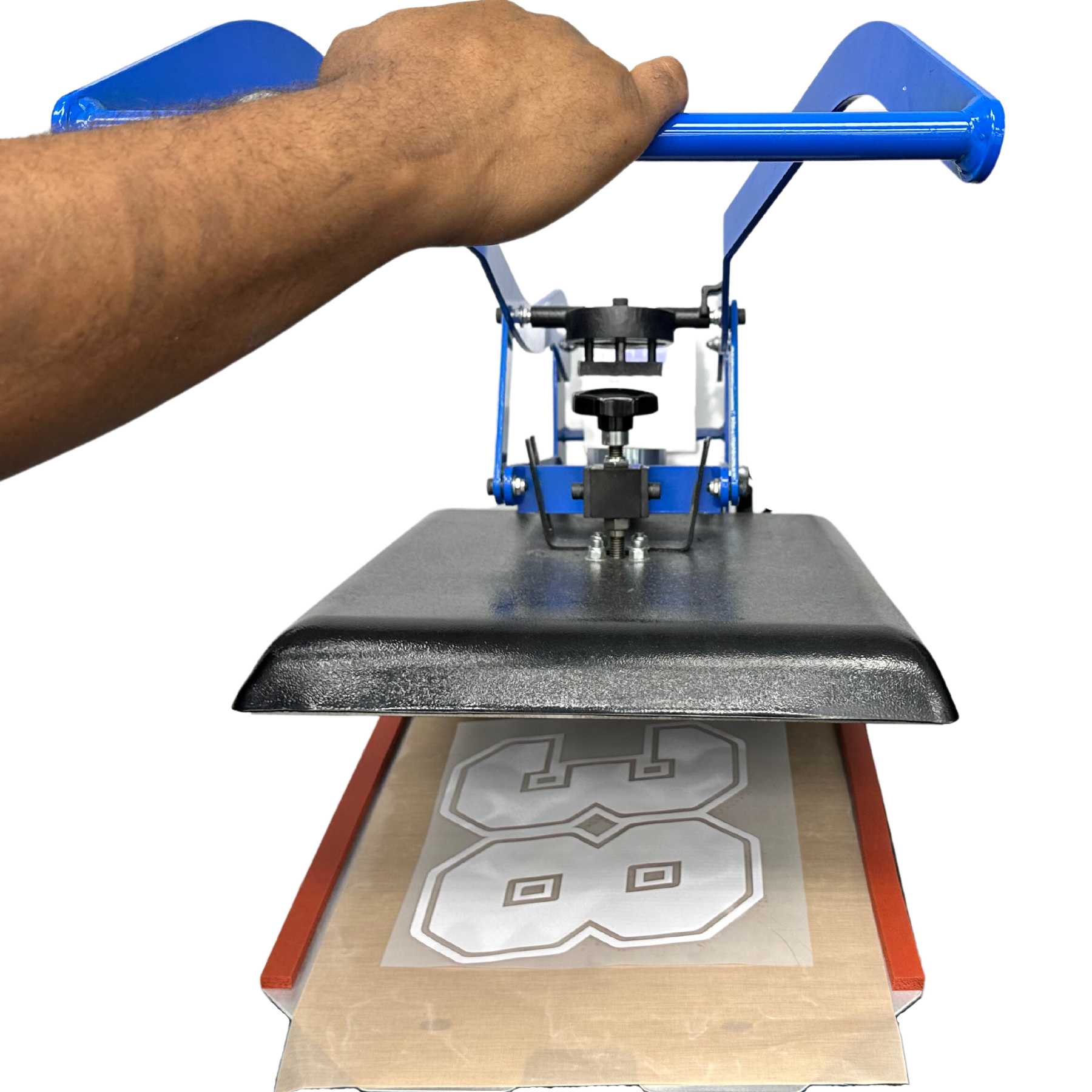

PRO TIP: FASTER PRODUCTION TIME

For faster production time use the Teflon sheet like a cooking tray, guiding the design transfer(s) in and out of the heat press. Leaving the heat press closed with the Cure-Tray inside, simply guide the Teflon sheet in/out of the press with the design transfer(s) in place. (Make sure the Teflon Sheet is completely level during this process to prevent the design transfer(s) from touching the heat press)

To keep the DTF Cure-Tray and Teflon Sheet clean and clear of debris, use a soft cloth, like a t-shirt, and a non-abrasive cleaner to wipe both sides of each.

ColDesi recommends that heat resistant gloves be worn in and around all heat press equipment.

© 2024 ColDesi Incorporated. All rights reserved