Have you ever thought about adding a white toner printer to your embroidery business?

You have—probably more than once. But something always gets in the way.

What if this time, you actually went for it?

With one, you could double your range of products, reach clients you’ve never reached before, and save time on projects that don’t need full embroidery.

Think about what that could mean for your business…

● Which new products could you add?

● Who might find your work that hasn’t yet?

● How much time could you save if some products didn’t need full embroidery?

Whatever answers you thought of, DigitalHeat FX has a line of white toner printers that can make them happen.

Here, we’ll take a closer look at how white toner printing can complement your embroidery work, the practical reasons to add it to your business, and the ways it can help your business grow.

And finally, we’ll explain why, out of all the options out there, DigitalHeat FX is the one you’ll actually want on your desk every day.

Enough of the intro, let’s get into it!

Introduction: The Next Step for Embroidery Businesses

Let’s start with something simple; what exactly is white toner printing, and how does it work? Once we’re on the same page, we can build from there.

In its simplest form, white toner printing is a process that lets you make full‑color transfer sheets and apply them to light, dark, or even transparent surfaces.

And the way it works is simple. The printer lays down a white underbase onto a special PET film, then adds your colors on top. Once printed, you use a heat press to transfer the design onto your material—shirt, bag, or anything else.

It’s really that simple.

And you don’t have to choose between white toner printing and embroidery. You can do BOTH. In fact, they complement each other beautifully!

Use white toner printer for designs with dozens of colors, fine gradients, small text or photorealistic detail (the kinds of things embroidery struggles with). Then, add embroidery to other parts of the piece for texture, depth, and that handcrafted look your clients love.

Let’s take another example to illustrate the point. Embroidery doesn’t always work well on very thin, stretchy, or delicate fabrics. Heavy stitching can distort or pull these materials.

In those cases, white toner printing is the perfect alternative. The transfer sits evenly on the surface without puckering or stretching the fabric.

And let’s be realistic, shall we? For anything with dozens of colors, fine gradients, or intricate textures, embroidery alone becomes simply impractical.

As you can see, each method has its own strengths, and combining them gives you the best of both worlds.

Now that you understand what white toner printing is, how it works, and why it pairs so well with embroidery, you’re probably wondering: why should I add it to my workflow? What’s in it for me?

The next section will answer exactly that.

Why Add White Toner Printing?

You’ve seen the question in the subheading above.

Have you thought about why you’d add white toner printing to your embroidery business?

We’ve already touched on a few good reasons, and the answer might already be forming in your mind.

But it’s worth taking a deeper look, because the benefits go well beyond that.

Low Overhead: No pretreatment, no screens, and minimal learning curve for existing embroidery staff. If your team already runs embroidery software and heat presses, they’ll pick this up in no time.

Speed & Efficiency: Transfers take minutes, not hours to complete. You can go from design to finished product in the time it takes to hoop a single garment.

Diversification: Expand beyond stitched products to full-color prints on T-shirts, hoodies, tote bags, wood, mugs, and more.

High ROI: Entry-level investment (starting around $ 2,995) quickly pays off through new product lines and faster turnaround.

And that’s just the start! When you put it all together, it really does make white toner printing seem kind of superior.

Combine this with your embroidery, and suddenly you can do things you couldn’t with thread alone.

Next, let’s explore exactly how these two methods work together.

How White Toner Complements Embroidery

Now we’re getting somewhere. Everything we’ve covered so far sets us up for a closer look at how white toner complements embroidery.

We’ve learned that, on its own, thread can create texture and depth, while white toner can produce full-color, high-resolution prints.

But by combining the two, you can do things neither could alone.

Here are a few ways to make them work together:

Mixed-Media Designs

You can layer white toner prints under or alongside embroidery to create a mixed-media effect that feels both visually dynamic and multi-dimensional.

Matching Apparel Sets

You can offer matching apparel sets, such as embroidered polos paired with printed tees or hats. Each piece stands out on its own, yet together they create a set that’s fun and versatile.

Use White Toner on Items Embroidery Can’t Handle

You can use white toner transfers on items or fabrics that are difficult to embroider, such as very thin, stretchy, or textured materials. This allows you to add detailed, full-color designs including fine lines, gradients, and small text on surfaces where embroidery might be impractical or visually limited.

Large-Area Designs

Embroidery is best for small to medium areas. You can use white toner transfers to cover large areas that embroidery machines can’t reach or would require splitting the design into multiple sections, allowing you to add detailed, full-color designs across the garment.

We bet you can think of more ways white toner printing can fit right alongside your embroidery work.

And when you put them together thoughtfully, you can create designs that are richer, more versatile, and visually striking than either method could achieve alone.

Which brings us to the next section.

Did you know? If you own Avancé 1501C embroidery machine, you can create a so-called modular embroidery setup by connecting multiple machines on the same network.

Business Impact: Profitability and Growth

Let’s get practical.

At the end of the day, every embroidery shop needs to see a clear return before adopting something new.

Which means it’s time to look at some numbers and example categories that show where white toner printing can make a measurable difference (and where it might not).

Cost Differences Between Embroidery and White Toner Jobs.

Embroidery looks great, but it can get expensive. Every embroidery design uses thread and backing, and you also have costs for digitizing, color changes, and machine maintenance.

Small runs or detailed designs can push the price per piece up quickly.

White toner printing works differently. Once your design is ready, you can print and press it with minimal material costs, mostly toner, transfer paper, and a little wear on the heat press.

For example:

An order of 12 embroidered logos might cost $5 to $7 per garment in production time and materials.

The same order printed with white toner could be $1.50 to $3 per piece.

The savings add up quickly over multiple orders.

Time Differences Between Embroidery and White Toner Jobs

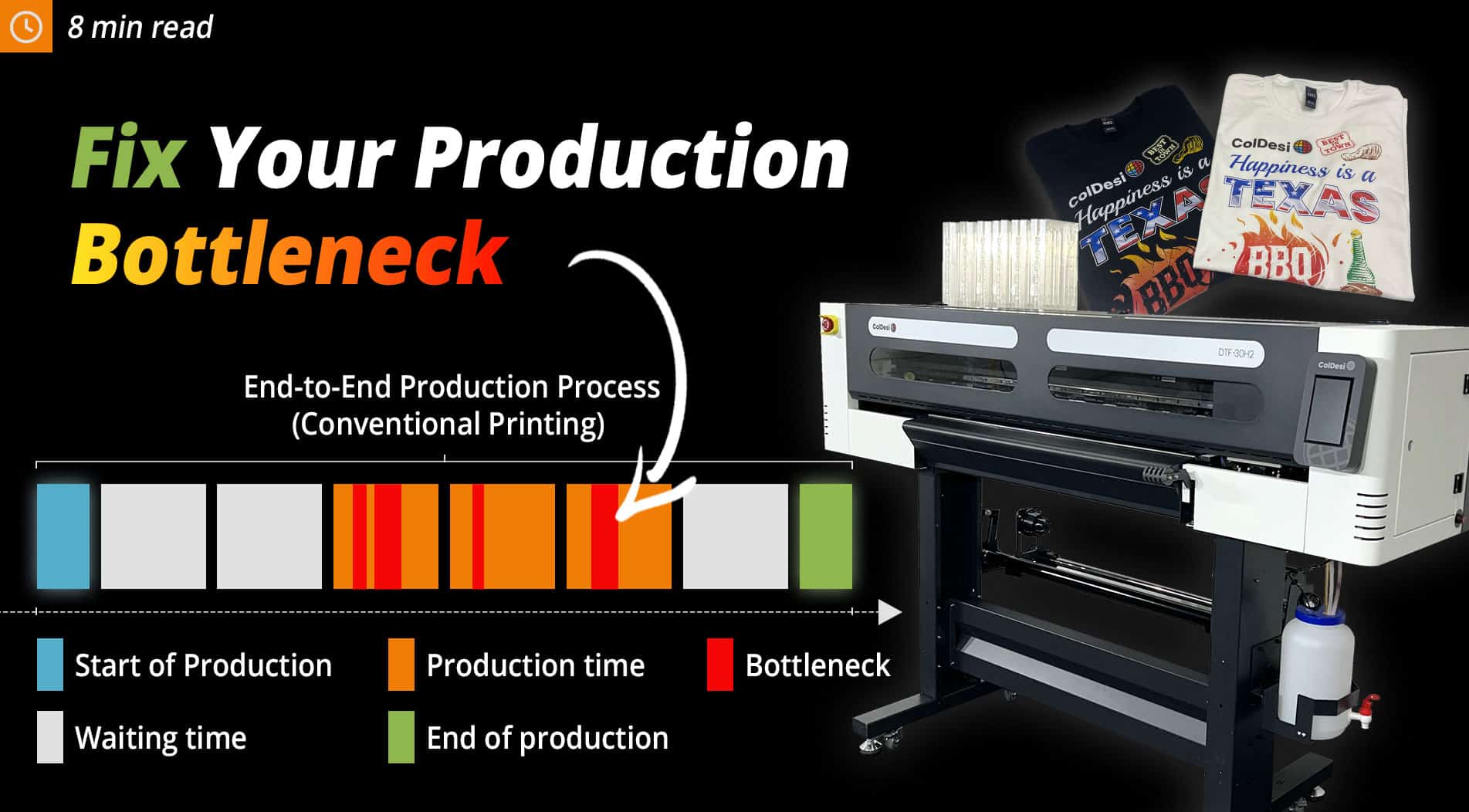

Time is money, right? Embroidery requires setup for each design — thread changes, hooping, machine calibration, and multiple passes for complex logos. Even small orders can take hours.

A batch that would take 2–3 hours to embroider? You can often finish it in under an hour with transfers.

One thing to watch: each garment still goes through the heat press individually. So for really big runs, pressing time can become the bottleneck. But for small-to-medium batches or varied designs, you save a ton of time.

Expanding Services with White Toner Printing Can Attract New and Returning Clients

Some clients come in looking for something embroidery alone can’t deliver: full-color logos, intricate gradients, or designs on fabrics that just won’t hold stitches.

By offering white toner printing alongside embroidery, you position yourself as a one-stop shop for custom apparel, increasing the likelihood of repeat business.

A basic embroidered shirt might satisfy one client, but a full-color printed design could excite three more.

When clients see they can get both embroidery and full-color prints from the same shop, it builds trust and makes their lives easier.

And when things are easy, clients come back.

The bottom line is, white toner printing perfectly complements embroidery by expanding what you can create, sell, and profit from.

Examples Product Categories That Boost Profits

Let’s take a closer look at some real-world product categories and projects where white toner printing adds real value.

Once you start thinking in terms of products instead of just decoration methods, the opportunities become obvious:

- Uniforms and Workwear

- Event and Promotional Apparel

- Fashion and Boutique Items

- Corporate Gifts and Specialty Items

- Spirit Wear

- Seasonal and Holiday Collections

- Limited-Edition Merchandise

- Baby and Kids Apparel

Think about the products that already make money for your shop. White toner printing gives you more ways to deliver those same products with full color, shorter lead times, better margins, and more room for creativity on every order.

You’re not changing what you sell, you’re just improving how you make it.

Why Choose ColDesi’s DigitalHeat FX Line

You’ve seen what white toner printing is all about, and it’s often better than machine embroidery for creating vibrant, full-color designs more quickly, at lower cost, and with higher profitability, especially on tricky or stretchy fabrics.

If these advantages sound appealing, ColDesi’s DigitalHeat FX line of white toner printers delivers just that.

It makes sense to see how.

Trusted Brand with Full Training, Support, and Bundled Software.

ColDesi’s DigitalHeat FX line delivers everything you need to get started. Each printer comes with full training, easy-to-use software, and support whenever you need it. Additionally, our free resources, like video demos, how-to guides, documentation, tutorials, and informative audio podcasts, can help you get the results you want.

Full Range of DigitalHeat FX White Toner Printer Models

We carry the complete lineup of DigitalHeat FX white toner printers, each designed to meet different production needs, speeds, and print sizes. Pricing generally starts around $2,995 and goes up to $13,995, with higher-tier models offering faster printing and larger maximum print areas.

Proven Results for Hundreds of Apparel Businesses Nationwide

Thousands of shops (of all sizes) across the country rely on DigitalHeat FX white toner printers every day. Business owners consistently report healthier margins, happier customers, repeat orders, and more profit per print!

Seamless integration with existing ColDesi embroidery systems (Avancé line)

Whether you already run an Avancé embroidery system, use another brand, or are just getting started, DigitalHeat FX white toner printers fit right into your workflow. If you’re an Avancé user, you’ll feel right at home. Using another system? No problem, it works seamlessly alongside what you already have!

Putting It All Together

Alright, so, here we are!

We’ve just about covered everything you need to know before adding white toner printing to your embroidery business.

We started from the basics, revisiting what the technology is, how it works, and why it matters. That gave us a good foundation to talk about how it compares to machine embroidery.

Embroidery will always have its place for that classic, high-end look on polos, jackets, and hats. But not every logo needs thread.

There are projects where white toner just makes more sense, and it is the better option across the board in terms of speed, versatility, color, design complexity, and the types of materials it can be applied to.

With that said, what is your next step?

Well, if you’re serious about growing your embroidery business and ready to take the next step, now’s the time.

Click below to explore the DigitalHeat FX printers.