Your trusty old embroidery machine has served you well, but it just can’t keep up with growing demand anymore.

Upgrading to a high production embroidery machine might be exactly what your business needs, and deep down, you probably already know it.

The right machine does more than increase output. It shortens turnaround times and lets you take on bigger, more profitable projects.

By now, you’ve likely started looking at your options (or even run the numbers) and you can already see the potential.

Part of you knows this is the logical next step. But another part is asking the tough questions:

● Do I really need this, or is it just a nice-to-have?

● How much will it cost, and will it pay off?

● Which models are actually worth considering?

This article will answer all of those questions and help you make the upgrade your business has been waiting for.

Let’s get right to it!

Introduction: Why Production Capacity Is the Next Step for Growing Embroidery Businesses

Let’s ease our way into this piece by asking: what does “production capacity” really mean for a growing embroidery business?

It’s not just about making more items. It’s about being able to say yes to bigger orders, tighter deadlines, and more complex designs.

Think about it. Right now, every order you turn down is money left on the table. Every project you rush or delay is a customer who might look elsewhere next time. And every design you avoid because it’s too complicated? That’s another opportunity gone.

The truth is, the difference between staying small and scaling up often comes down to one thing: equipment. It’s that simple.

Your current machine might handle the day-to-day jobs just fine, but it probably struggles to keep up with bigger orders or intricate designs without slowing you down.

That’s where high production embroidery machines come in. They let you do more. Bigger orders? You can handle them. Tight deadlines? You can meet them. Complicated designs? No problem.

In today’s market, that’s what customers expect—and what keeps them coming back.

With that kind of capacity, you’ll open doors to B2B contracts that used to be out of reach. You’ll see a faster ROI because these machines let you produce more, sell more, and earn more.

But timing is everything. So how do you know when it’s time to upgrade?

That’s exactly what we’re going to look at next.

Signs Your Embroidery Business Is Ready for a High-Production Upgrade

So, how do you know when it’s time to upgrade? Well, the signs are usually right in front of you.

But as the saying goes, you can’t see the forest for the trees. Sometimes you’re so close to things that it’s hard to spot the bigger picture.

Do any of these ring a bell?

1. You’re Turning Down Orders

If you’ve had to say “no” to clients because you simply couldn’t meet their timelines or volume requirements, that’s your first clue.

2. Consistent Backlogs or Long Turnaround Times.

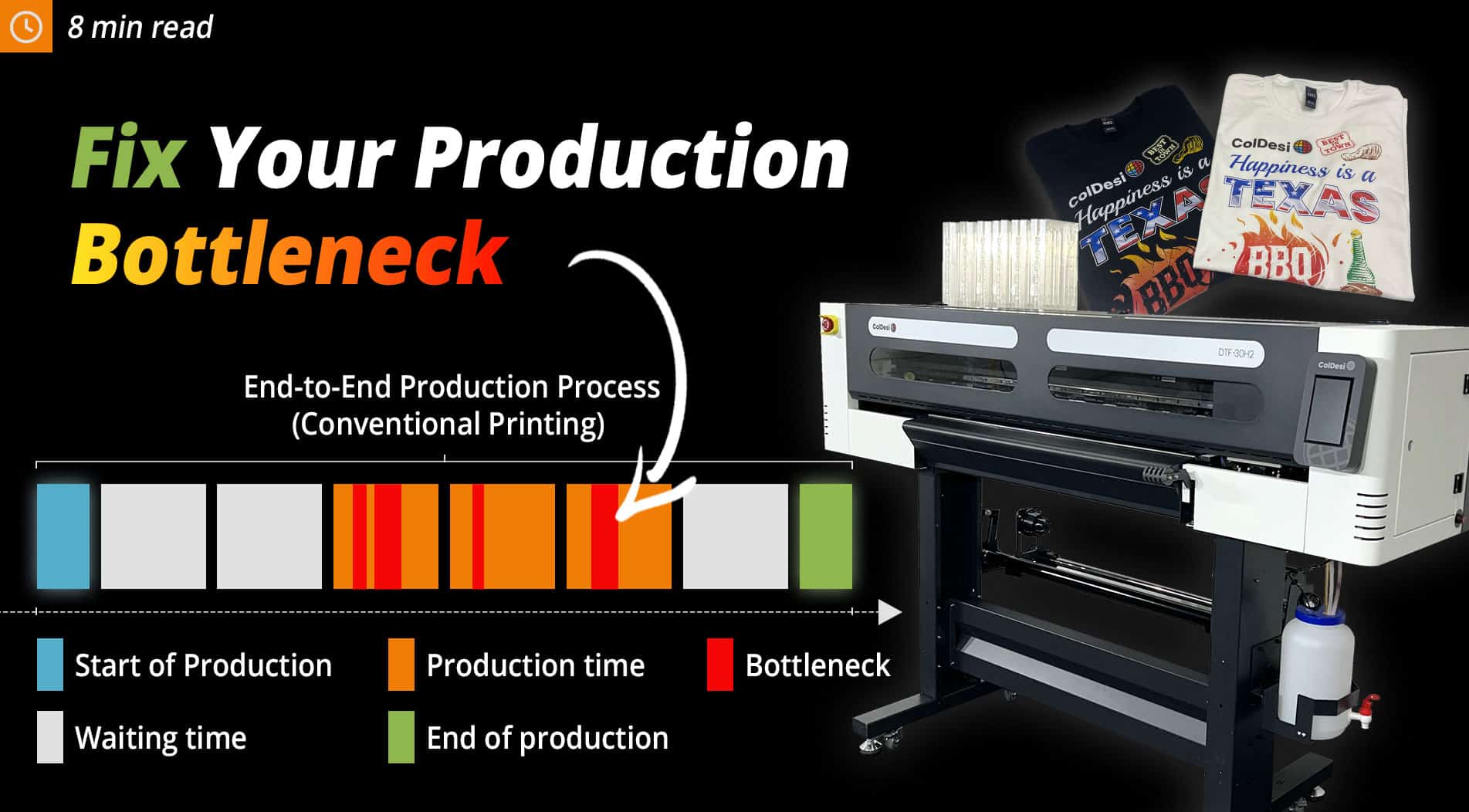

Backlogs might sound like a good problem to have. They mean business is steady, right? But when orders keep piling up and customers are left waiting longer than they should, often asking “How much longer?”, that’s not growth. That’s a bottleneck.

3. Losing Larger Contracts Due to Limited Output

You’re ready for bigger jobs and bigger clients, but your machines aren’t. When opportunities come knocking, you’re forced to turn them away.

4. Needing to Hire Additional Staff Just to Keep Up.

Adding hands can help, but if you’re constantly hiring just to get orders out on time, it’s not a manpower issue, it’s a production issue. More people won’t fix machines that are maxed out.

5. Your Machines Are Running Nonstop (and Still Not Enough)

If your equipment is running around the clock but you’re still behind schedule, it could be time to upgrade.

6. You’re Struggling With Complex or Large Designs

Your current machines may handle simple logos and small designs just fine, but when clients request larger or more intricate designs, limitations in sewing area or number of thread colors can make things tricky. You might find yourself splitting designs or running multiple passes just to complete a single project. If this is happening often, it’s a sign your equipment might not be keeping up with the work your clients are asking for.

7. Desire to Diversify Product Offerings

You want to expand into uniforms, hats, corporate gear, or wholesale runs, but your current machines can’t handle the load.

If any of these signs feel familiar, take a moment to reflect.

Have you noticed yourself hitting one (or more) of these points lately? And if you’re thinking, “Yeah, that sounds like me,” don’t worry, there are plenty more we could list.

What Makes a Machine “High Production”?

If you’ve been following along, you’re probably asking yourself: what really sets a high production embroidery machine apart from the one I’m using now? (You may already have some clues.)

And that’s the right question to ask.

In short, it all comes down to engineering.

High production embroidery machines are built to run all day, every day, with minimal downtime.

Typically, these machines come with multiple heads, larger embroidery fields, touchscreen control panels, among other advanced features.

These machines are feature packed, yes — but more importantly, they’re built to handle heavy workloads, multiple jobs, and long hours without constant babysitting.

Here’s what that looks like in practice:

Multi-Needle Speed and Efficiency

Multi-needle embroidery machines let you stitch multiple colors without constantly stopping to change threads. By using several needles, they can automatically stitch designs in different thread colors. This setup also enables the machine to complete complex designs much faster than a single-needle machine. The result is smoother workflow, less downtime, and more finished pieces in less time.

Larger Embroidery Fields

A larger embroidery field allows you to create bigger, more intricate designs without re-hooping or splitting your artwork. That means fewer seams, fewer alignment errors, and less time spent piecing designs together, giving you a cleaner, more professional final product.

Smart Automation Features

If you’re constantly pausing to swap colors or trim threads, you know how much time it eats up. High production embroidery machines automate these steps with built-in thread trimming, automatic color changes, and break detection that stops the job if a thread snaps.

Many models also include anti-flagging technology that adjusts stitching speed on steep angles for cleaner results, plus onboard memory to store and access hundreds of designs instantly.

Continuous Operation with Minimal Downtime

As we came to learn, one of the biggest advantages of high production embroidery machines is their ability to run hour after hour, day after day with hardly any interruptions. Features like automatic thread trimming, color changes, and break detection let the machine keep working while you focus on other tasks.

Connectivity/Software Capabilities for Streamlined Workflow.

Modern high-production embroidery machines feature advanced connectivity options, including Wi-Fi and USB, and work with a variety of digitizing software, allowing users to easily transfer, load, and send designs from computers or other connected devices for a streamlined and flexible workflow.

Together, these features define a high production embroidery machine. In the next section, we’ll put the spotlight on ColDesi’s Avancé line of commercial embroidery machines, as well as on HappyJapan models.

Spotlight on Growth-Ready Machines: ColDesi’s Avancé & HappyJapan

We’ve gone over the whys, whens, and whats. Now, meet the machines that answer those questions — ColDesi’s Avancé and HappyJapan high production embroidery machines.

If these names are new to you, not to worry, we’ve got you covered! In this section, we’ll explore their features, capabilities, and what sets each model apart so you can find the perfect fit for your workflow.

Avancé 1201C – Let’s start with the Avancé 1201C. It’s a 12-needle commercial embroidery machine designed for small businesses, startups, and home-based studios that want commercial-level results without going fully industrial just yet. Compact, fast, and surprisingly capable, this model proves that big capabilities can come in small packages.

The 1201C can sew up to 1,000 stitches per minute, which is impressive for a machine its size. Measuring 23 x 23 x 63 inches and weighing about 176 pounds, it is actually the smallest and lightest Avancé model to date, but don’t let that fool you. It’s built to keep up with demand.

Up front, there’s a 10.1-inch full-color LCD touchscreen control panel that makes managing designs and settings simple. You’ll find 28 built-in fonts and a library of up to 4,000 designs, so you can start creating on day one!

And because Avancé likes to make life easy, the 1201C includes everything you need to get started — hoops, frames, thread, backings, and more. To top it all off, it comes at a more attractive price point than its bigger brother, the Avancé 1501C, which we’ll cover next.

Avancé 1501C – The Avance 1501C shares many features and components with the 1201C model. The control panel and user interface are identical, as is the onboard memory and library of fonts and designs it comes with.

It also includes the same training, support, and uses the same embroidery supplies.

The difference? It’s larger. In every sense of the word.

The physical size of the machine measures in at 33 x 30 x 63 inches. Some might take that as a drawback, but it’s an intentional design feature to accommodate a larger embroidery area and hoops that can fit the machine.

It was designed with power-users in mind, right down to the speed at which it operates (which caps out at 1,200 SPM). Combine all of that with 15 colors of thread on deck, and you have an embroidery machine that ticks all the boxes.

It’s worth mentioning that you can start with a single unit and, of course, expand by adding more machines as needed, creating a so-called modular embroidery setup by connecting multiple machines on the same network.

For a more detailed look at modular embroidery systems and their benefits, check out this article.

HappyJapan Multi-Head Embroidery Machines – Then there’s the HCR3 series from HappyJapan!

These industrial-grade multi-head embroidery machines are built for high-volume, high-speed textile and apparel production.

Unlike single-head machines, they feature multiple independent sewing heads, which means you can embroider identical designs simultaneously on several items.

What’s more, they combine the flexibility of a single-head machine with the output of a multi-head system. Each head can run independently or in sync, giving you complete control over your production process.

The series also comes in a variety of configurations, ranging from 2-head machines all the way up to 12 heads.

Overall, the HCR3 series functions as a modular embroidery system.

If you want to learn more about each model and configuration, click here to explore the full lineup.

And there you have it, a closer look at the Avancé 1201C and 1501C, as well as the HappyJapan HCR3 multi-head series. Now it’s up to you to pick the one that fits your needs and requirements.

But we’re not quite done yet. Once you’ve chosen your machine, it’s time to think about how to get the most out of it.

In the next section, we’ll share with you a few tips to ensure you have a smooth transition.

Maximizing ROI and Preparing for the Transition

In this section, we’ll cover the key steps you should take before, during, and after the transition, so your new machines deliver maximum ROI and integrate seamlessly into your workflow.

Evaluate & Optimize Your Workspace Size

And it probably starts with making sure you have enough space. High production embroidery machines, particularly modular systems like HappyJapan’s HCR3 series or clustered Avancé 1501Cs, can take up a significant amount of room. The good news is that you don’t have to set up everything at once. With Avancé 1501C, you can start with one or two machines and expand your system as your business grows, which also makes it easier to manage limited space.

Even if your workspace is small, there are ways to make it work. Many multi-head machines—4, 6, 8 heads and up—will not fit in a home-based business. You cannot put a 4-head machine in your back bedroom, but single-head machines are much more flexible. By placing one or two Avancé 1501C machines in different rooms and sending designs over a network cable, you can keep production moving efficiently without needing a large commercial space.

This approach allows you to scale production over time, making the most of your available space without requiring a warehouse or big commercial facility.

Train Staff on New Equipment

Even if your staff is experienced with older embroidery systems, new machines come with entirely new features that require training. That’s why your team will need training to get up to speed on these new features.

At ColDesi, we offer the best training and technical support in the industry. Our resources include how-to guides, detailed documentation, video demonstrations, tutorials, and informative audio podcasts. We teach not only the basics of embroidery but also the advanced capabilities of your new equipment.

Maximize ROI from Day One

It’s important to think about how people will discover the services and products you offer. When you bring new embroidery equipment into your workshop, make a plan for showing clients the new designs, apparel, and accessories you can create, as well as the expanded embroidery services you can provide at scale. Doing this from the start ensures your equipment starts generating value immediately. If you wait, nothing will really change. Customers will keep buying the same way they always have. Remember, people buy what you put in front of them, so make sure they see all the new possibilities your equipment makes possible.

While we’re at it, you can learn about some special machine embroidery tools and accessories in this article.

Conclusion: Power Your Growth with the Right Equipment

Congratulations! You’ve made it to the end of the article!

Throughout this page and our time together, we’ve learned what it takes to grow a successful embroidery business.

By now, you’ve probably answered a big question: Am I ready to upgrade to a high production embroidery machine?

And if you are, you now have a clearer idea of what that process looks like and which specific machine models might be the best fit for your business.

If you’re ready to take that next step, now is the perfect time to invest in one of the high production embroidery machines we discussed, like the Avancé or HappyJapan.

Let’s make this your most productive and profitable year yet!