Customization is no longer tied to massive, centralized production facilities. More brands are moving toward micro-fulfillment centers. These smaller, local hubs are often set up closer to their customer base. This shift makes it possible for businesses to cut shipping times and keep their inventory lean. As a result, they can turn around on-demand or small-batch orders quickly.

Why Micro-Fulfillment Matters in Customization

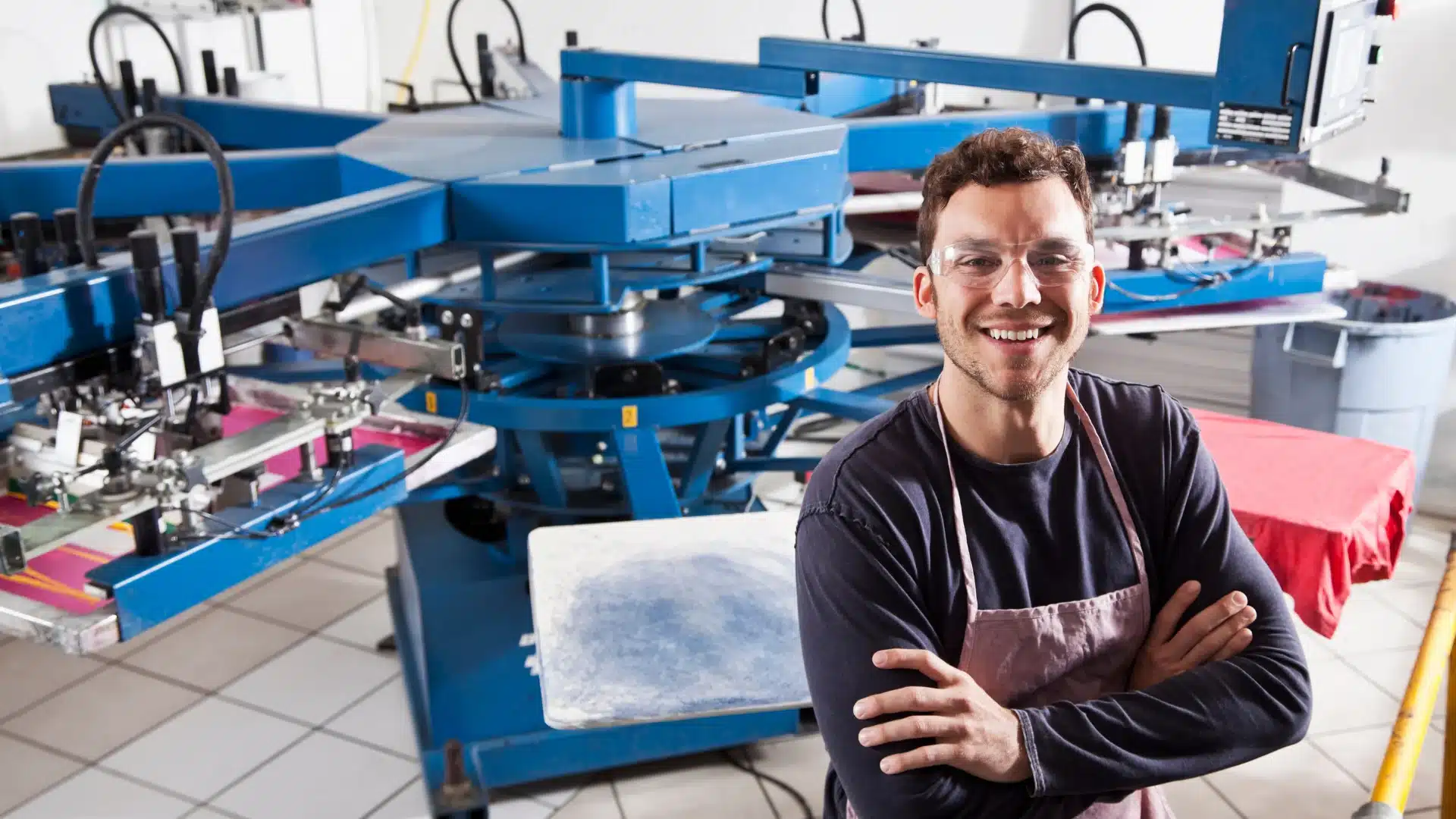

Consumer demand for personalization and faster delivery is reshaping production models. Traditional screen-printing shops are built for large runs and high-volume output. That model creates long lead times and ties up capital in inventory.

Micro-fulfillment centers powered by digital printing operate differently. They handle short runs efficiently, manage just-in-time inventory, and adjust quickly to shifts in customer demand.

Key business benefits include:

- Faster delivery: Orders are produced locally and shipped directly to nearby customers.

- Lower risk: Small-batch production reduces unused stock.

- Increased flexibility: Hubs pivot quickly to new designs, seasonal items, or one-off orders.

- Scalable growth: New hubs can be added to more markets without the cost of a large facility.

Micro-fulfillment also plays into larger retail and sustainability trends. By producing closer to consumers, apparel businesses reduce carbon emissions tied to long-haul shipping, and by working on-demand, they avoid the costly overproduction that has plagued the fashion industry for decades. In fact, studies show micro-fulfillment can cut last-mile costs by up to 50% while boosting customer satisfaction with faster delivery windows.

Types of Customization Businesses and Micro-Fulfillment Potential

Screen Printing Micro-Fulfillment

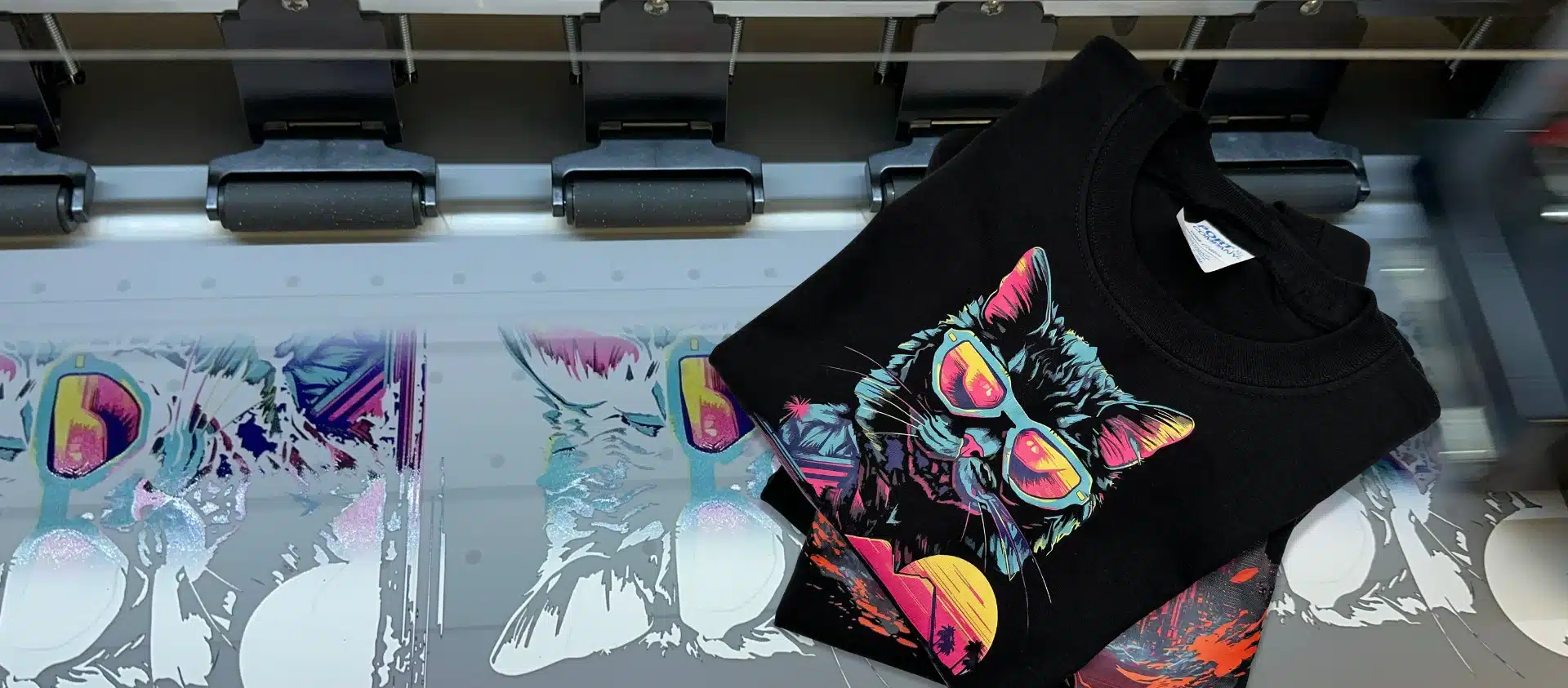

DTF Printing Micro-Fulfillment

DTF is the easiest and most profitable technology to anchor a micro-fulfillment strategy.

DTF Printing Micro-Fulfillment Centers

- Versatility Across Materials – Apply on cotton, polyester, blends, and performance wear without specialized adjustments.

- No Order Limitations – Profitable for both one-offs and micro-batches.

- Faster Order Processing – Prints and presses transfers in minutes.

- Lower Overhead and Floor Space – Compact systems compared to the bulk of screen-printing setups.

- Consistency Across Distributed Hubs – Digital workflows ensure color accuracy and repeatability.

- Reduced Environmental Impact – Water-based inks and transfer methods minimize chemical waste.

Advantages of DTF Micro-Fulfillment Centers

- Rapid Market Response – Immediate reaction to trends, events, and customer demand.

- Lower Capital Investment – Less infrastructure required than embroidery or screen shops.

- E-Commerce Integration – Direct connections to online stores streamline automation.

- Scalability – Easily expand with new hubs in different regions.

The e-commerce connection is especially powerful. With DTF integrated into online ordering systems, businesses can automatically trigger production the moment a customer clicks “buy.” No guesswork, no excess inventory—just a seamless path from digital storefront to physical product.

Leveraging DTF Printing for Fast-Fashion Success

Fast fashion thrives on speed, adaptability, and the ability to deliver personalized products in small, profitable runs. Screen printing struggles to meet these demands due to its heavy setup requirements, higher costs for multicolor designs, and longer production times. DTF printing provides a direct solution to these challenges.

With DTF, businesses gain the ability to create detailed, full-color prints without time-consuming screen preparation. Designs can be produced in minutes, enabling quick response to emerging trends and market shifts. This capability is critical in fast fashion, where consumer interest can change rapidly.

The financial benefits are equally strong. DTF reduces overhead by removing screens, emulsions, and large drying equipment. It also lowers waste and simplifies inventory management, making it easier to operate lean and efficient production cycles. Businesses can take on both single-item orders and larger batches without sacrificing profit margins.

For screen printing businesses, adopting DTF is more than adding a new decoration method. It represents a shift to a faster, more flexible model designed for the realities of today’s apparel market. By integrating DTF solutions, companies position themselves to compete effectively in fast fashion and establish a stronger foundation for long-term growth. (Learn More)

Why ColDesi

ColDesi has guided thousands of businesses into digital printing with industry-leading equipment and training. Its printers are engineered for performance, scalability, and ease of use. ColDesi’s dedicated support keeps operations running at peak performance and ensures long-term consistency.

By choosing ColDesi, business owners gain more than equipment. They gain a trusted partner with decades of experience building successful customization companies. With ColDesi DTF solutions, micro-fulfillment centers become reliable, profitable, and positioned for growth.

What truly sets ColDesi apart is its ecosystem approach: DTF printers, shaker/dryers, inks, software integrations, and hands-on training are all designed to work together. This ensures micro-fulfillment hubs not only launch successfully but also maintain consistent quality across multiple locations. For entrepreneurs, that means scaling with confidence and protecting brand reputation as you grow.

Have questions about DTF Printers? Live Chat with a DTF Pro or call 877-793-3278. Our team is here to guide you on the path to success.