1. Incorrect Film Handling

The Mistake: Mishandling or improperly storing DTF film can lead to moisture absorption, dust contamination, or physical damage, such as creases and fingerprints. These issues affect ink adhesion and print consistency.

Incorrect film handling can introduce multiple issues into the DTF printing process, affecting both print quality and equipment performance. DTF film is sensitive to contaminants like dust and oils from hands. Moisture and static can lead to poor ink adhesion, smudging, or surface defects during printing and transfer. Mishandling can also result in physical damage, such as scratches, creases, or edge curling. These issues can interfere with media feeding and alignment, and this may cause head strikes or jams during printing. Exposure to high humidity, extreme temperatures, or sunlight can degrade the film, reducing its ability to properly receive ink and adhesive powder. Operators should manage film with clean, dry hands or gloves. Films should be stored in a controlled environment. Media should be loaded carefully to prevent feed issues. Proper film handling preserves material integrity. It protects the printer and ensures every transfer meets professional production standards.

- Always store DTF film flat or rolled in its original packaging.

- Keep the film in a dry, climate-controlled environment.

- Handle film with clean, lint-free gloves to prevent contamination.

- Allow film to acclimate to room temperature before printing.

Choosing the Right DTF Film for Superior Print Quality

Not all DTF film is created equal. Using the wrong film can compromise print quality, consistency, and efficiency. Learn about the essential qualities that define high-performance DTF film. From preventing defects to ensuring reliable results, the right film plays a critical role in maximizing your printer’s potential. Learn why ColDesi’s specially profiled DTF film is designed to work seamlessly with its printers, helping businesses achieve professional, high-quality results without costly trial and error. READ MORE

2. Inconsistent White Ink Circulation

The Mistake: White ink sedimentation can clog printheads if not circulated properly. White ink is heavier than CMYK inks and settles more quickly.

- Use printers with built-in white ink circulation systems, like ColDesi DTF printers.

- Perform daily maintenance routines, including gentle agitation of ink cartridges.

- Follow manufacturer-recommended maintenance schedules for flushing and cleaning.

ColDesi Introduces CAIMS: A Breakthrough in Digital Ink Management

ColDesi has launched the ColDesi Advanced Ink Management System (CAIMS). This system changes how ink is delivered and maintained in digital printing. It includes the SMART Cartridge System and Ink Sentry Application. CAIMS removes the need for disposable cartridges, prevents contamination, and automates maintenance with flushing cycles. Its advanced white ink circulation keeps the printer clog-free, extends printhead life, and improves print quality. First used in the ColDesi 30H2 DTF Printer, CAIMS raises the bar for reliability, cost savings, and long-term performance. READ MORE

3. Improper Powder Application

The Mistake: Uneven or excessive application of hot-melt adhesive powder leads to poor bonding, rough textures, or even powder drops that contaminate the printer.

- Use automated shaker/dryer systems for consistent powder application.

- If applying manually, ensure even coverage and remove excess powder thoroughly.

- Monitor powder storage conditions to prevent moisture absorption.

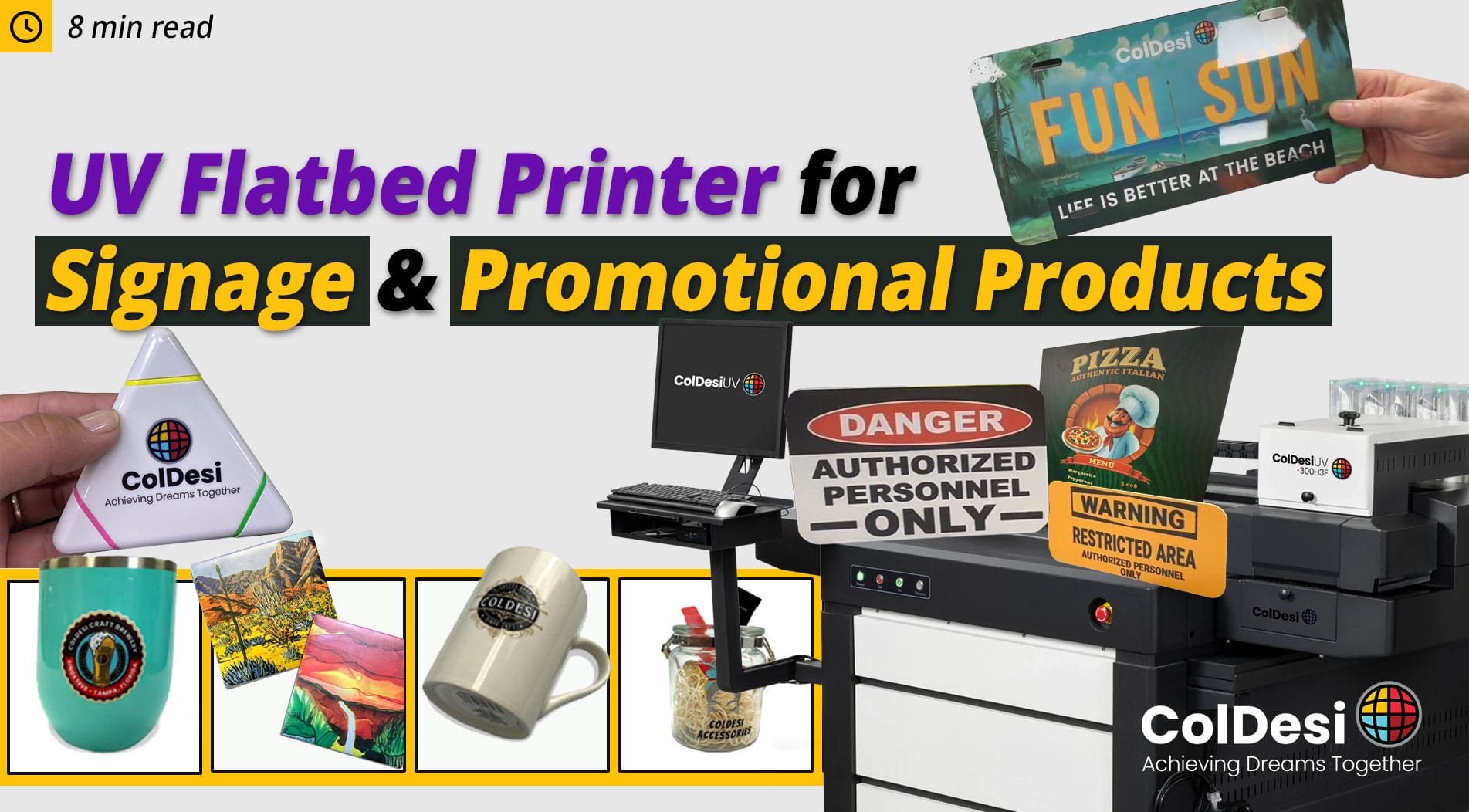

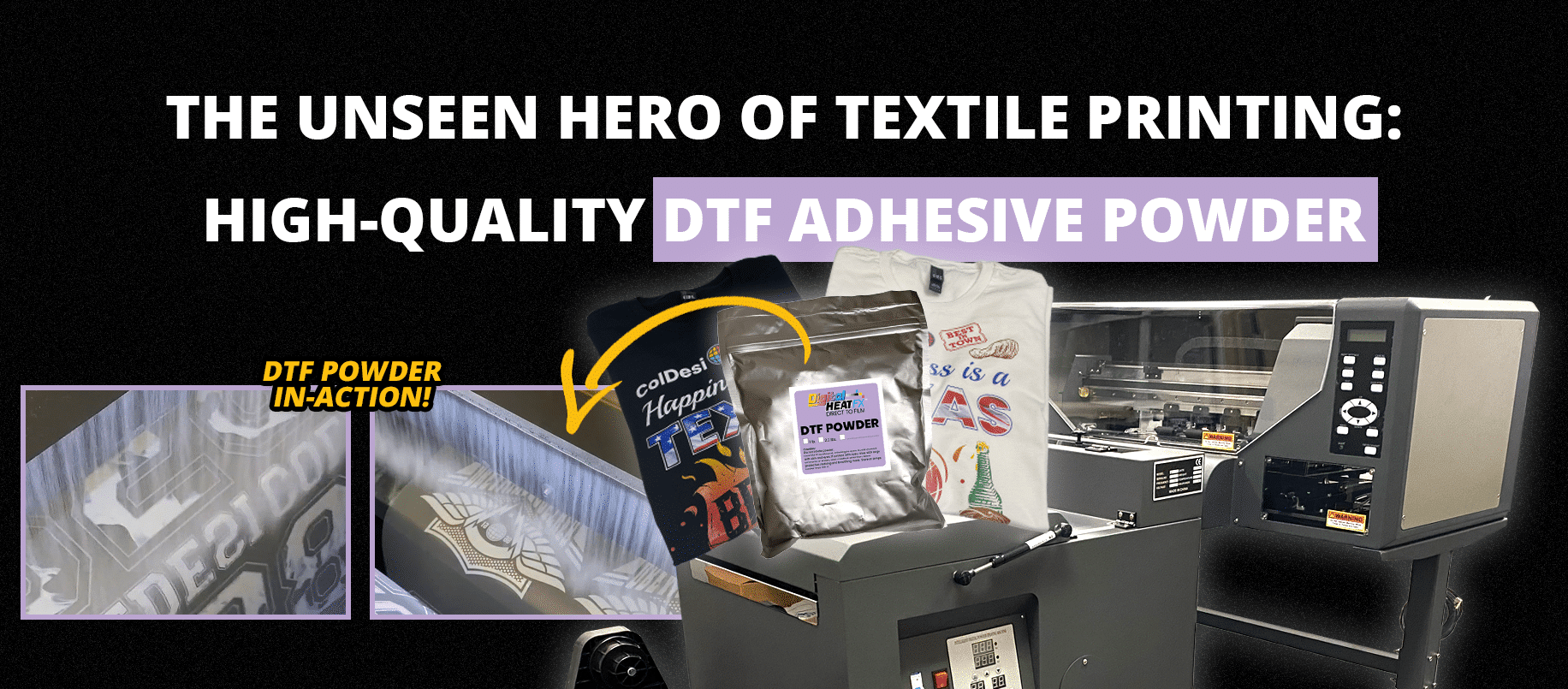

DTF Adhesive Powder: The Unsung Hero of Print Quality

DTF adhesive powder is key to how the transfer looks, feels, and lasts. High-quality powder gives a soft feel, easy peeling, strong ink adhesion, and a solid bond on many fabrics. ColDesi tests its powders to work perfectly with their DTF systems. This removes guesswork and provides decorators with consistent, professional results. READ MORE

4. Incorrect Curing Temperatures and Times

The Mistake: Under-curing leaves adhesive tacky and weakens durability, while over-curing can scorch the film or reduce print vibrancy.

- Follow the specific temperature and dwell time recommendations for your powder and film combination.

- Use calibrated curing equipment to maintain consistent results.

- Periodically evaluate cured transfers for wash and stretch performance.

5. RIP Software Misconfiguration

The Mistake: Incorrect RIP settings can lead to color inaccuracies, banding, poor ink laydown, or an insufficient white underbase.

- Use RIP software designed and profiled for your printer and ink set.

- Apply correct color management profiles and ink limits.

- Verify resolution and print mode settings for each job type.

- Schedule periodic RIP software updates and training.

6. Neglecting Humidity and Environmental Control

The Mistake: Unstable room humidity affects ink viscosity, powder performance, and curing consistency.

- Maintain a consistent production environment (typically 50-70% humidity and 60-80°F temperature).

- Use dehumidifiers or humidifiers as needed.

- Allow equipment and consumables to stabilize in the production area before use.

7. Skipping Preventive Maintenance

The Mistake: Delaying or skipping maintenance leads to clogged nozzles, wasted film, costly downtime, and premature equipment failure.

Skipping preventative maintenance on a DTF printer can cause major problems. DTF printers use heavy pigment inks. If you don’t clean them regularly, ink builds up in the nozzles and printheads. This leads to clogs, banding, poor prints, and costly repairs. Regular maintenance keeps the ink system clean and the printheads working correctly. This helps maintain sharp colors, smooth details, and high-quality prints. Even small debris can cause streaks, bad colors, and prints you can’t sell.

Skipping maintenance also wears out important parts faster. Capping stations, wipers, dampers, filters, pumps, and ink lines all suffer. This strain shortens the life of the printer’s most expensive parts. Motors and belts also wear down faster. Breakdowns often happen at the worst times, like during big orders or tight deadlines. Regular maintenance catches problems early, reducing emergency repairs, and keeping jobs on schedule.

Financially, regular maintenance costs much less than big repairs or replacing expensive parts. It also saves money by avoiding wasted materials from bad prints. Many manufacturers need proof of maintenance to keep the warranty valid. Skipping service may void your warranty, leaving you to cover repair costs. Preventative maintenance protects your reputation and helps your business keep customers happy.

- Follow a strict preventive maintenance schedule provided by your manufacturer.

- Clean printheads, capping stations, and wiper blades daily.

- Keep a log of maintenance tasks and service records.

- Work with trusted technical support partners like ColDesi for advanced service needs.

Protect Your DTF Investment with Proactive Maintenance

Regular maintenance prevents downtime and helps your equipment last longer. In this article, ColDesi shares simple daily and preventative steps. These tips help your printer run smoothly and reliably. ColDesi follows manufacturer guidelines and offers expert training to support this process. Their approach helps businesses stay productive, avoid costly repairs, and reduce wasted supplies. With proper maintenance, your DTF printer can run at peak performance for many years. READ MORE

Avoid Mistakes and Get Better DTF Results

Fill out the form below or call 877-793-3278 to learn more about ColDesi’s line of DTF printers.