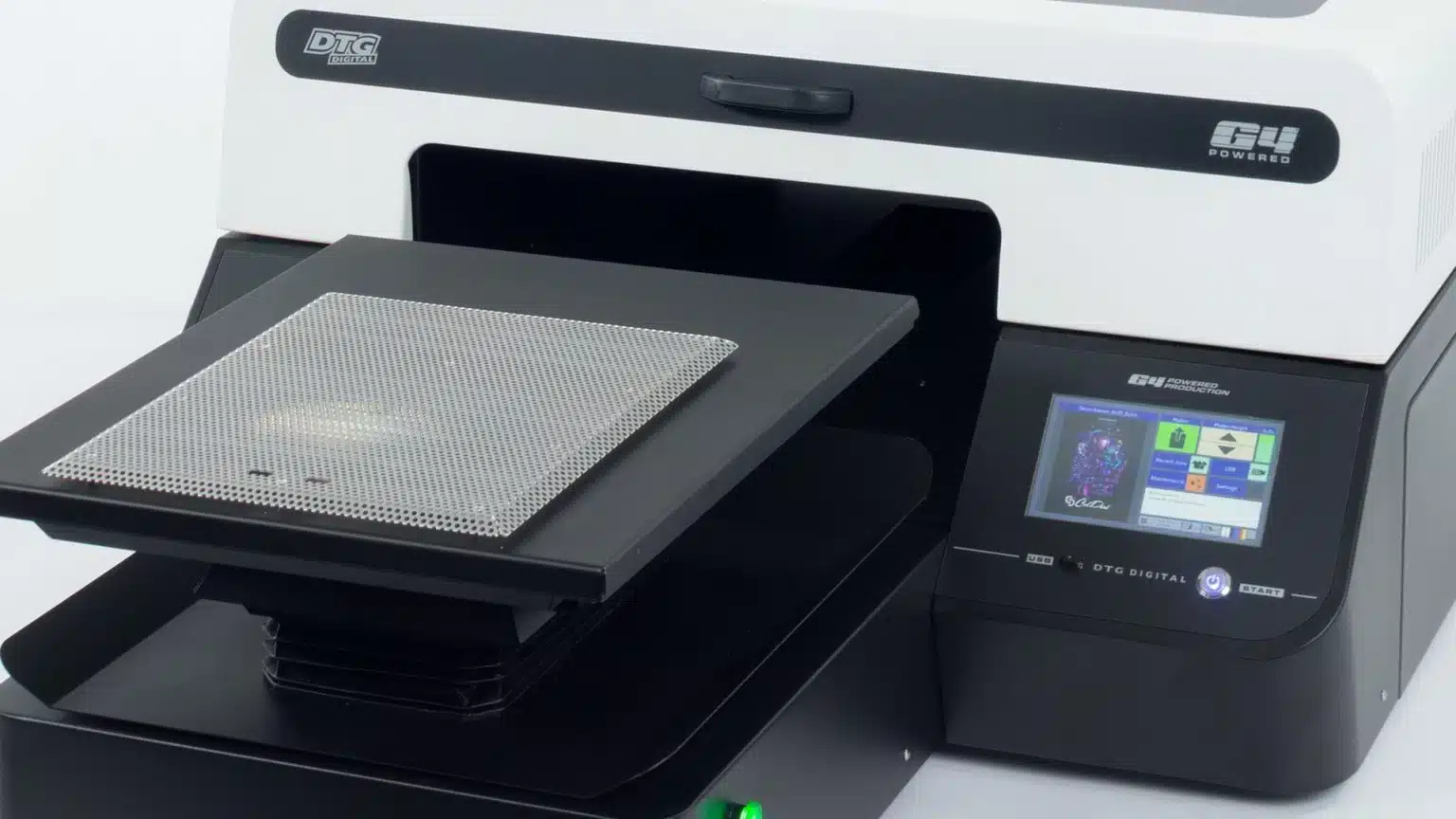

Industry Insiders Still Rank the G4 the Best DTG Printer You Can Buy

The demand for razor-sharp, high-detail prints continues to drive the popularity of DTG printing. Manufacturers are enhancing their machines with cutting-edge software and top-tier components.

As the custom printing industry transitions from screen printing and vinyl cutting, DTG printing remains a go-to solution. DTG printers are often more reliable and efficient than traditional customization techniques, giving businesses a powerful tool to meet demands without sacrificing quality or productivity.

Why the DTG G4 Stands Out in 2025

1. High Print Quality

- The G4 excels at producing vibrant, photo-quality prints with exceptional detail and color gradients. This makes it ideal for intricate designs and images, especially on cotton or cotton-blend garments.

- DTG ink is absorbed directly into the fibers of the fabric, resulting in a soft hand feel that customers appreciate. The print blends seamlessly into the material without a noticeable texture.

- Many DTG printers use water-based inks that are environmentally friendly. This appeals to businesses looking to align with eco-conscious consumer trends.

- The G4 allows businesses to print single pieces or small runs economically, eliminating the need for large inventories and enabling just-in-time production. This is ideal for e-commerce platforms offering personalized or unique designs.

- The G4 allows businesses to print single pieces or small runs economically, eliminating the need for large inventories and enabling just-in-time production. This is ideal for e-commerce platforms offering personalized or unique designs.

- DTG integrates easily into online stores for automated workflows. Platforms like Shopify and Etsy often pair well with DTG setups for direct print fulfillment services.

- Continued improvements in DTG technology have enhanced speed, durability, and material compatibility.

- DTG printing has been a proven solution for years. Many businesses have the infrastructure, training, and customer base tailored to DTG operations. Transitioning to newer methods can require significant investment and retraining.

- DTG remains the go-to for high-quality cotton apparel. Its ability to cater to specific fabric types ensures it remains a versatile option.

Use Cases for DTG Printing:

- Custom T-Shirts: Ideal for small businesses or artists creating unique designs.

- Corporate Merchandise: High-quality prints for promotional or branding purposes.

- Limited-Edition Apparel: Perfect for short runs or highly detailed designs.

DTG G4 Build Quality

The G4 sets itself apart with high-quality components and rigorous pre-testing by ColDesi. Each machine undergoes a thorough inspection process, ensuring it performs flawlessly out of the box.

One of its standout features is the print head, which includes a computer-controlled damper reservoir. This system uses dual sensors to track ink levels, ensuring precise operation. The dampers also reduce air bubbles by using a built-in diaphragm to automatically release excess air.

Exclusive Features of the DTG G4

A highlight of the DTG G4 is its patented Vacuum Platen. This feature revolutionizes the shirt-loading process, eliminating the need for time-consuming tasks like tucking fabric into gaskets or using adhesive hoops.

With the Vacuum Platen, loading a shirt is as simple as draping it over the platen. The vacuum holds it securely in place in about five seconds. Operators can be confident in perfect alignment before printing even begins, streamlining production and minimizing errors.

DTG Maintenance Requirements

Maintenance is often a pain point for DTG printers. The G4 simplifies daily upkeep significantly.

Traditional DTG printers require meticulous cleaning to manage overspray. The G4’s Vacuum Platen reduces overspray by pulling ink directly into the garment. This keeps the machine cleaner and improves print quality by ensuring more ink adheres to the shirt.

G4 Performance

In terms of overall performance, the G4 ranks as the best DTG printer in 2025. It prints fast, loads even faster, and outpaces traditional shirt-loading systems.

Consider the time savings during shirt loading and unloading:

- Traditional tuck-style platens take about 35 seconds per shirt with skilled operators.

- The G4’s Vacuum Platen reduces this to just 10 seconds, even for untrained users.

Why the DTG G4 Continues to Lead

For more information, visit our website and chat with a Pro or call 877-793-3278.