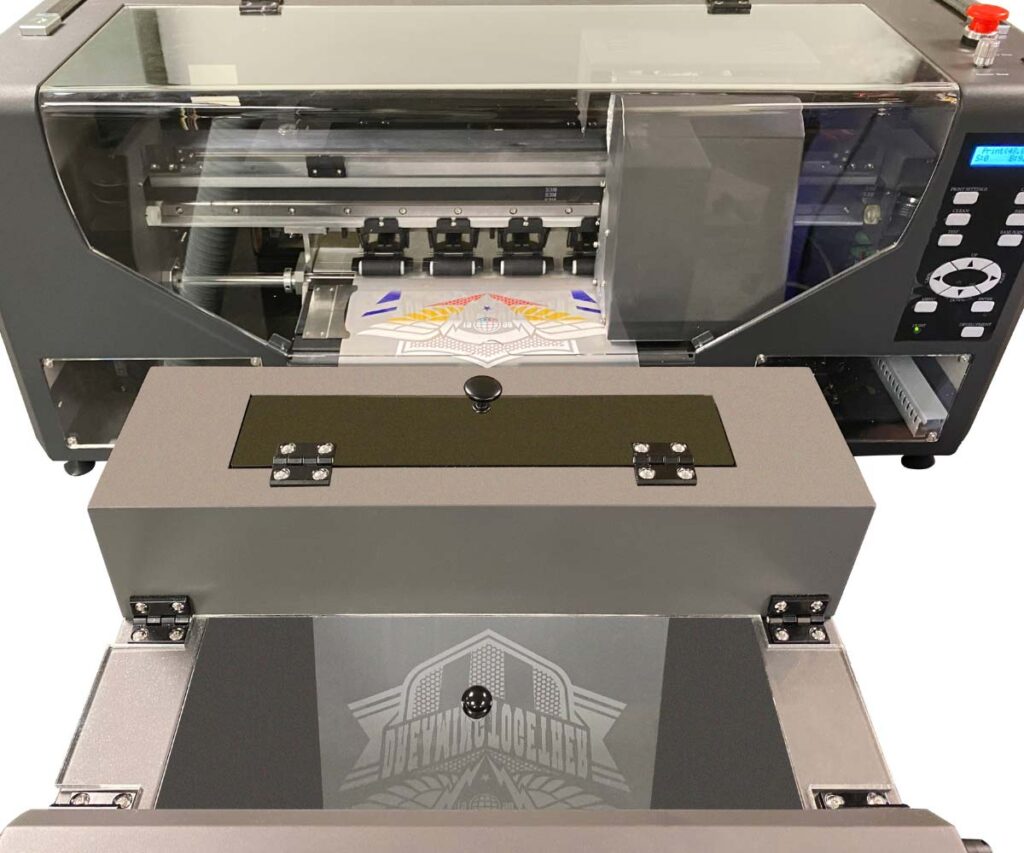

How much money can you make with the new, compact direct-to-film printer, the DTF-12H2? We did an ROI study to let you see the potential.

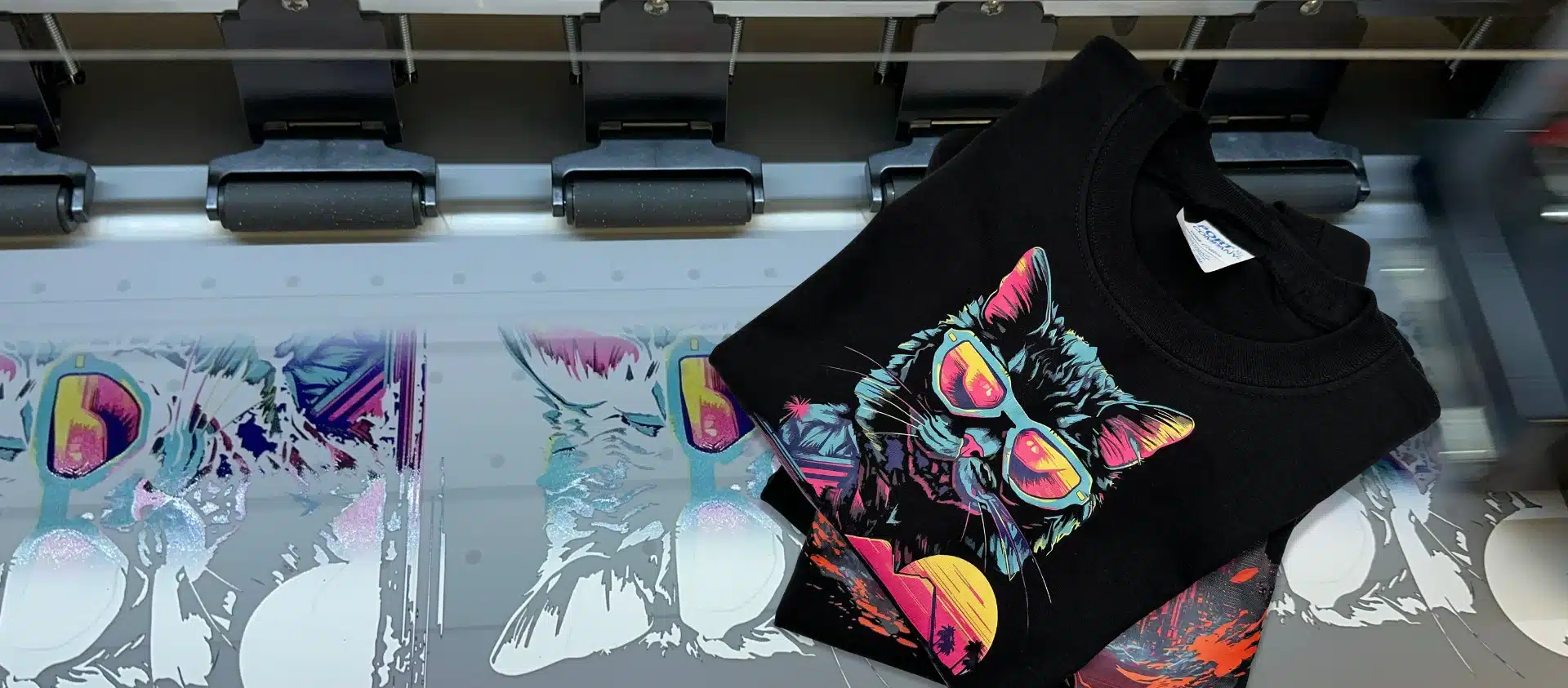

For this study we are using a full color image of a Maine Coon Cat with an Attitude. The image is 9.26” wide by 13.8” tall. Our example bases off 100 shirts – Gildan Ultra Cotton – printed and pressed.

To determine time and costs we did a run of 10 designs on the DTF-12H2 and then multiplied our numbers by 10 and added the costs and time associated with the lead out of the film at the end of the prints.

Ink, film, and powder costs are based on “one off” pricing, however, buying larger quantities will increase discount – thus reducing your Cost of Goods sold.

Blank Apparel Cost | Gildan Ultra Cotton Tee

We chose to use the Gildan Ultra Cotton for a couple of reasons. First off it is a shirt that does not lend itself well to DTG, is commonly used for screen printing and is affordably priced.

It comes in a variety of colors and sizes, including youth and plus sizes. This makes it a great universal t-shirt.

Examples we based our pricing comparison on were also quoting the Ultra Cotton as well. For the purpose of this ROI calculation, we assumed a delivered price of $3 per shirt for the order.

Print Materials Cost | Ink, Powder & Film

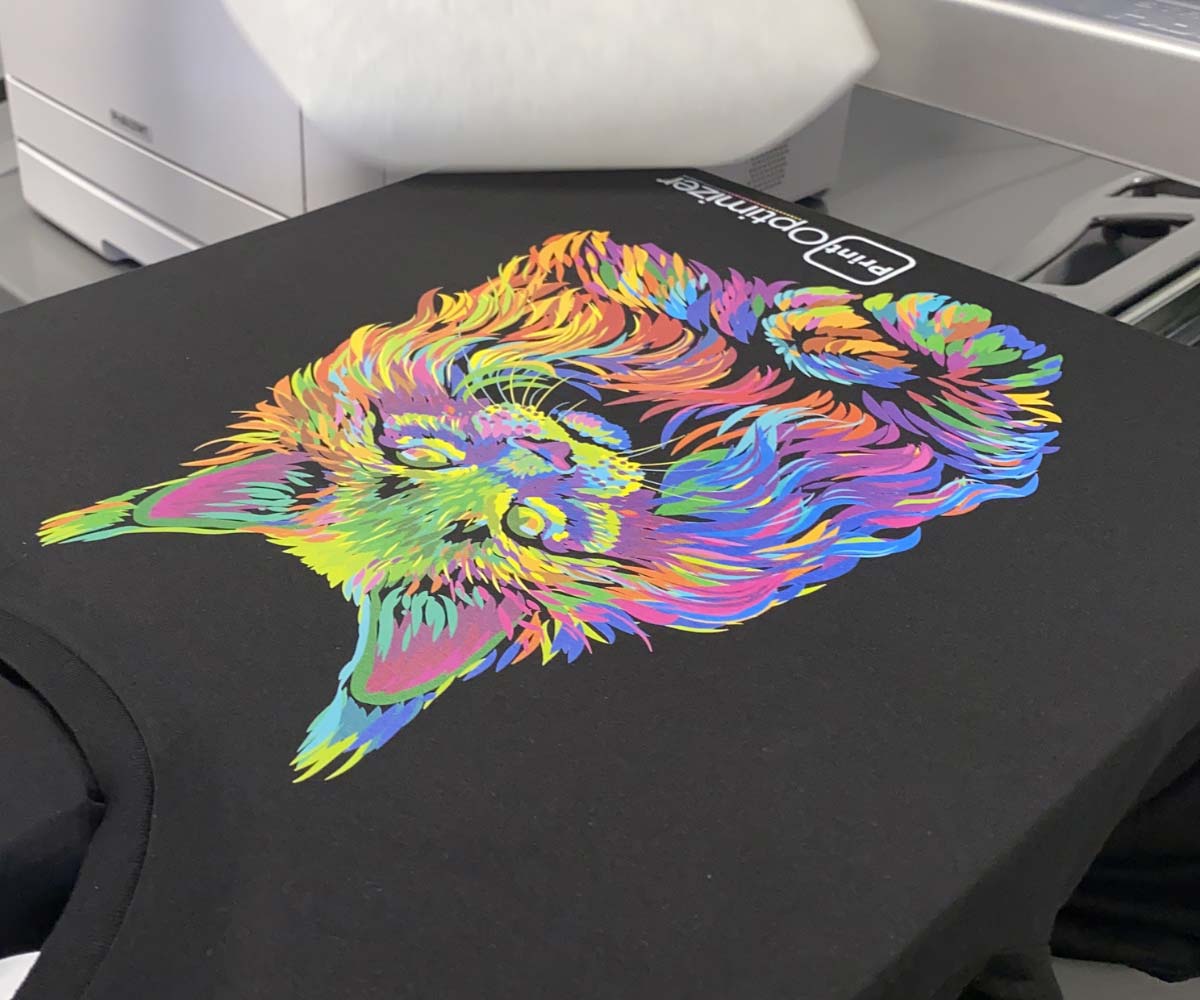

We processed the image (10 copies) through the PrintOptimizer software and the total calculated price for the prints (ink, film and powder) was $6.85 total for all 10 prints.

Job Cost for 10 Transfers:

$2.84 Film + $2.01 Powder + $2.00 Ink = $6.85 for 10 transfers

This means each transfer costs $0.69 to produce.

$6.85 / 10 = $0.69 per transfer

And to produce 100 of the transfers, it would have cost $68.50 in material.

$6.85 x 10 = $68.50 for 100 transfers

At the end of the print job we send a film advance print file that uses $2.17 in ink, film and powder. (The Film Advance File is only done once, at the end of day when you finish ALL your jobs).

$68.50 (100 transfers) + $2.17 (film advance file) = $70.67 Total Transfer Costs

According to our above calculations the totally costs to produce this 100 shirt order is $370.67.

You can find DTF Printer Supplies for the DTF-12H2, DTF-24H2, and DTF-24H4, here.

Total Job Costs | Print Materials & Blanks

$68.50 (100 transfers) + $2.17 (film advance file) = $70.67 Total Transfer Costs

$3.00 (Gildan Tee) + 100 = $300 for 100 Blank Gildan Tees

$300 (blanks) + $70.67 (transfers) = $370.67* total cost to produce a 100-shirt order. (*plus, labor costs)

Print Time | DTF-12H2

Print time for these was just under 18 minutes for all. Based on our example we are printing 100 shirts so total print time would be 180 minutes or 3 hours.

18 mins (10 transfers) x 10 = 180 minutes (3 hours) to print 100 transfers

Now we will add together the total print time, plus the print time to advance your film (which you only do at the end of day when you finish ALL your jobs).

It takes 3 hours and 10 minutes from the time the first print starts until the last image exits the shaker/dryer.

3:00 (print time for graphics) + 9:30 (film advance print file) = approx. 3:10

Then, we will add a generous 50 minutes to trim the roll of prints down to be ready for pressing. This puts us at 4 hours to print, cut and trim all our transfers getting them ready for production.

3:10 (print time) + :50 (cut/trim time) = 4 Hours Total

Press Time | Cotton T-Shirt

The recommended press time for a cotton shirt is a 10 second initial press with a 5 second finishing press.

10 sec (transfer press) + 5 sec (finish press) = 15 sec per shirt

15 secs per shirt + 100 shirts = 1,500 seconds or 25 minutes

However, we will add extra time to this for putting the shirts on the press, positioning the transfers, and opening and closing the press.

We recommend, the DigitalKnight DK20 for DTF transfers because they have an auto pop-up feature. This will cut down your production time and is easier the laborer’s body when doing high-volume production.

Our generous time estimate for pressing 100 shirts is 50 minutes.

Total Production Time | Print & Press

If you add the total print time to our total press time you get a Total Production Time of 4 hours and 50 minutes for 100 shirts.

3:10 (print time) + :50 (cut/trim time) + (:50 press time) = 4:50 total production time

Putting It All Together | Total Job Profits

Now we can calculate the return on investment or in other words, your profit, for a job like this.

Based on our online research, the retail value for full color for digital or 8 color screen printed shirts is about $15 per shirt.

On the popular big t-shirt order websites, a similar 100 shirt order would sell for $1,500 (we actually found them for even higher).

So, if you sold this 100 shirt order for $1,500, that would leave you with a profit of $1,129.33.

$1,500 (retail value) – $370.67 (cost) = $1,129.33 net profit

If we allow $100 for labor ($20 per hour) we still net over $1000 in profit for 5 hours of work. And, in reality, the printer was only running for 3 hours of that.

It is fully conceivable that you could queue up another job and have it printing while you were pressing this order or trim and press the first part of the roll while the second half was printing.

What does my Return on Investment look like?

With a monthly lease payment around $340 a month, it is feasible to make your monthly lease payment on the DTF 12H2 in under 2 hours of work!

Another way to look at it is that you can conservatively make nearly $86,750 per year by running one such job per week for 52 weeks!

Now that is what I call solid ROI!