Top Commercial Embroidery Machines

Understanding the Essentials of Top Commercial Embroidery Machines Equipped with advanced features, commercial embroidery machines expand design possibilities and heighten efficiency. Versatile in their fabric

Understanding the Essentials of Top Commercial Embroidery Machines Equipped with advanced features, commercial embroidery machines expand design possibilities and heighten efficiency. Versatile in their fabric

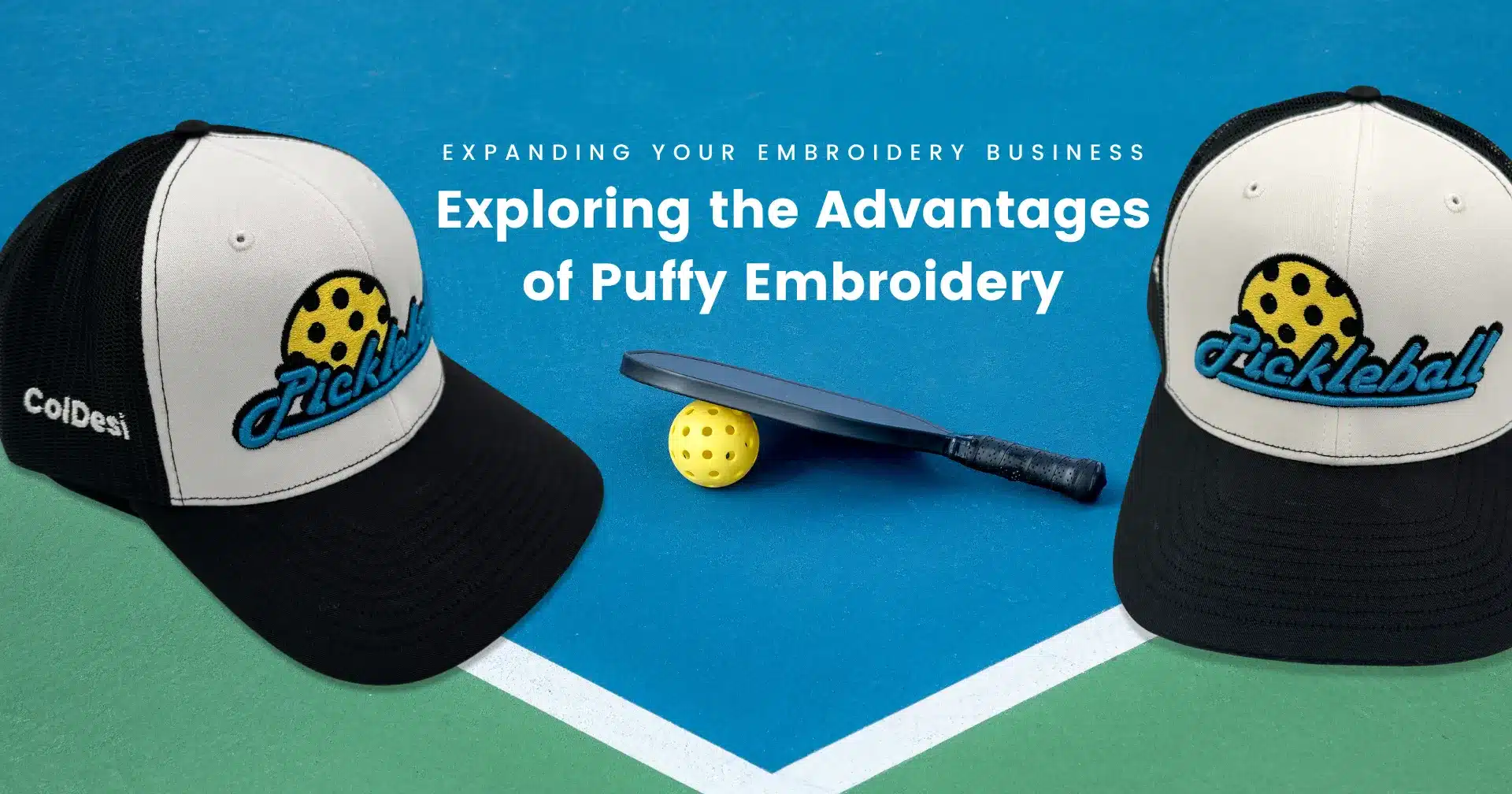

As you grow your business and diversify product offerings, incorporating puffy embroidery opens new avenues. Adding puffy embroidery into your embroidery business presents a lucrative

Launching a Profitable Hat Embroidery Business Venturing into hat embroidery is an excellent avenue to transform your creativity into a profitable venture. Entrepreneurs passionate about

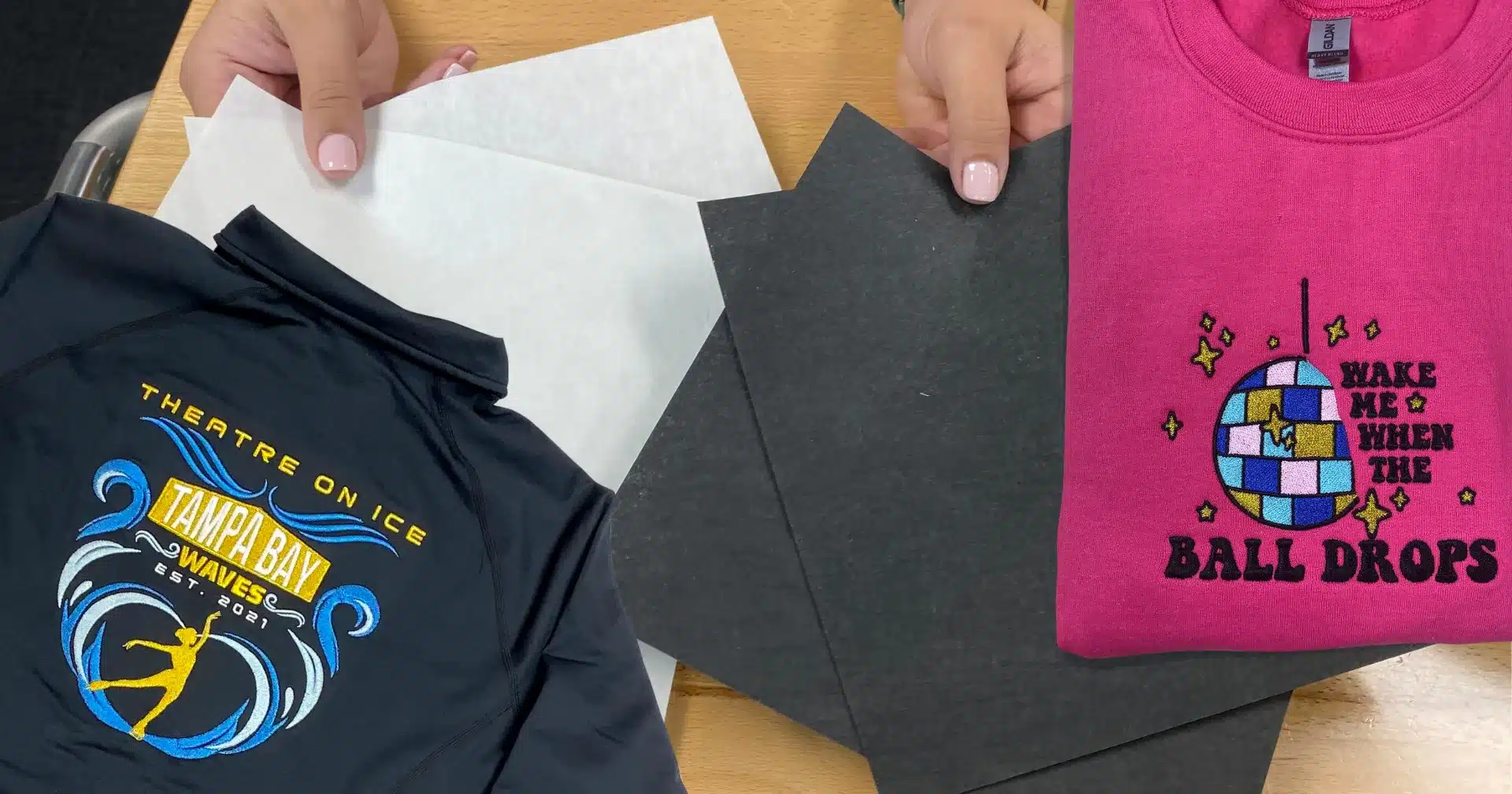

Learn about the different types of embroidery stabilizers and how to choose the perfect backing for your fabric and design needs.” This succinctly communicates the core value of the article, emphasizing the educational content on selecting the right embroidery backing to match specific project requirements. It invites readers to explore the importance of backing in achieving high-quality embroidery results. For more detailed insights, visit the ColDesi article directly

Customized Patches Can Generate Profit Custom patches are a versatile and profitable business to enter. Which is why its a good idea to pick up

In simple terms, a computerized embroidery machine is a modern upgrade to your regular sewing machine. These machines come packed with cool features and functions.

The main difference is that they’ve got computerized parts, making it super easy for you to handle various sewing tasks with just the push of a button.

Welcome to the future of embroidery with the enhanced Avance 1501C. A 15-Needle Commercial Embroidery Machine, tailored to improve cap embroidery enthusiasts like you. The

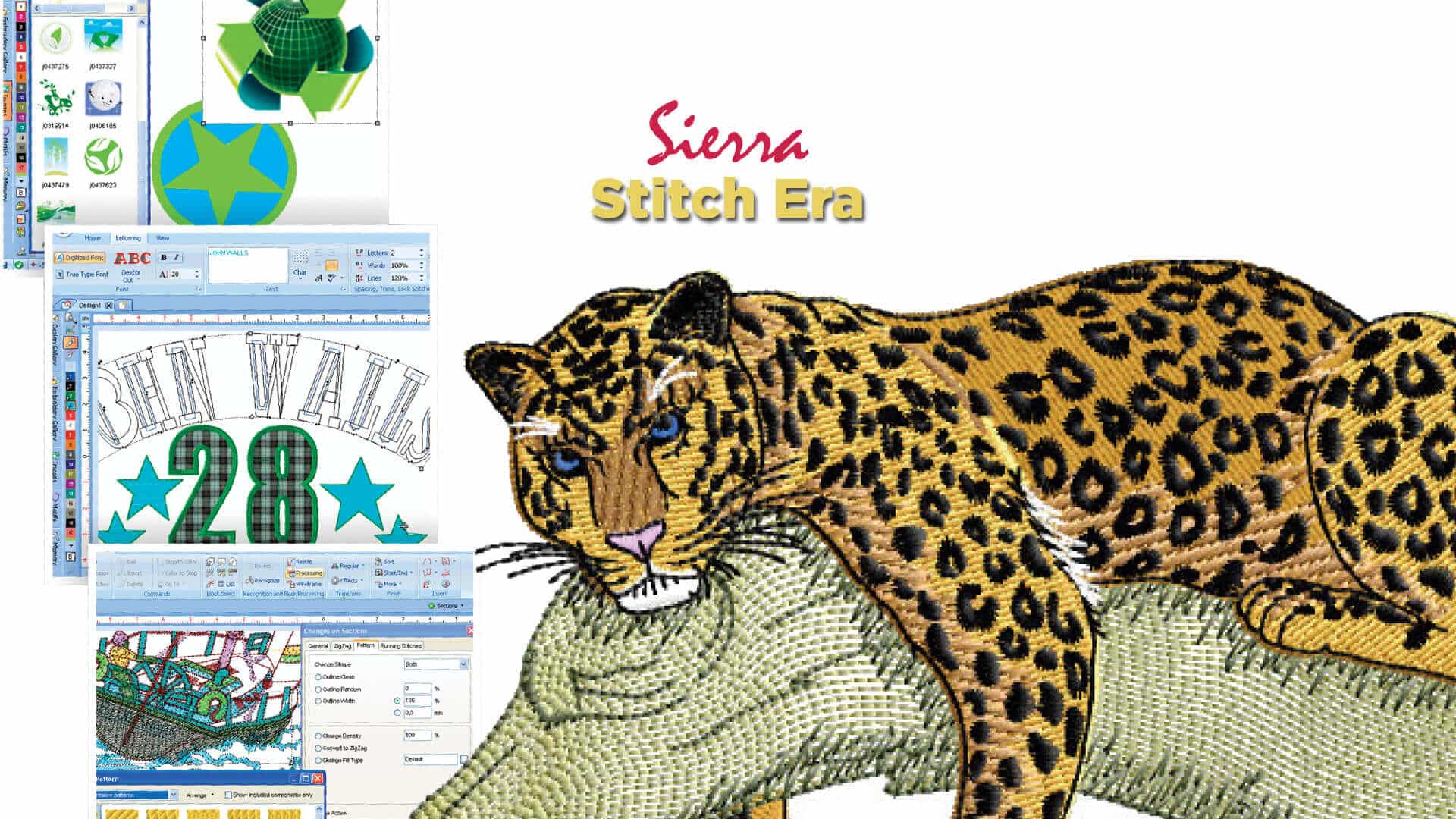

Sierra Stitch ERA Liberty is the first choice for business embroidery design! There are four reasons the Liberty improves over the free Stitch ERA Universal.

A commercial embroidery machine can be a great asset for any business, large or small. Embroidery machines allow businesses to personalize products with logos, names,

Table of Contents But one thing you’ll want to do first is to look at your business backwards. Well, at least in the reverse order

© 2024 ColDesi Incorporated. All rights reserved