When faced with embroidery registration problems, most shops just blame digitizing. Before you start pointing fingers, think!

Other factors can lead to poor registration. The quicker you find them, the faster you can go back to making money!

The classic excuse for poor embroidery registration is digitizing. It is not just a problem with customer-supplied artwork, bitmap or raster images; you can have glitches with “simple” images such as keyboard lettering and stock designs.

Problems commonly blamed on poor digitizing often fall into three broad categories:

- Improper setup for the specific substrate used.

- Manipulation of the design parameters.

- Using the design on a substrate different than the one it was digitized to be on.

Poor setup for specific embroidery projects

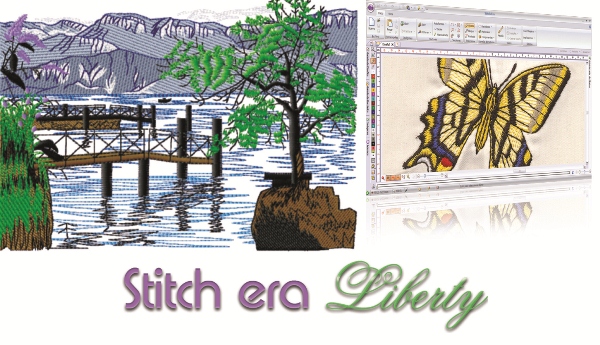

Normally, incorrect setup means that a digitizer might not be experienced enough with an embroidery digitizing program (like Sierra’s Stitch ERA Liberty) or did not pay enough attention to the details of the project. The most crucial element of the digitizing process is compensating for the push-pull that is part of every embroidery process. This begins with a good understanding of which substrate you will be sewing on and its specific characteristics. Go through much more in relation to Embellishment. It also helps to have the proper design training; the CorelDraw Training CD Set is an 8 CD Series with 12 hours of video training for designed exclusively for embroiderers, screen printers, and garment graphics companies.

Not understanding the fabric

Some textiles are considered more “stable” than others. If you are working with more unstable material, like thin and sheer fabrics, other elements might be required to ensure both quality and registration stay at optimum levels. Poor digitizing may come from not understanding the tendency to push-pull during embroidery, and not predicting or compensating for it. In a majority of cases, this is leading cause of poor registration.

Sizing issues

In some cases, an embroiderer can get a well-digitized design and try to either resize it or change a few of the parameters, to satisfy a client or their own needs. Altering the original design takes the exact features that guarantee top quality embroidery, changes them and alters the anticipated quality. By altering a design—either sizing it up or down, skewing it or rotating it, so it sews on a bias—you have changed the design away from the way it was originally digitized and tested. You now take a chance of creating an inferior finished product. To be fair, with the vast range of software on the market today, it is increasingly difficult to predict how a particular program will modify the original design. In some programs, simple resizing can change stitch effects after reopening the design, even if no other changes were made. In addition, if you change the sizes of an embroidery design, you will also most likely affect registration. Adjusting stitch length, especially in thin fabrics like satins, could have a negative effect. Altering or modifying a design should only be done on a copy of the design, not the actual file. And don’t forget to check it carefully!

Different fabrics provide different results

Sewing designs on different garments, material or substrates other than the one it was digitized for, can cause a host of quality issues. There is no design that sews great on every fabric. Each fabric will have different features, so the design needs different digitizing for each one. Realistically, an embroidery shop will not want to pay for different versions of the same design. Most often, they take what they get and try to use it on every fabric, with crossed fingers and hoping it works out. When a design doesn’t translate well on different substrates, the embroidery shop will immediately blame digitizing.

Registration problems: not just for custom designs!

This also happens with stock designs. For example, buying something online could sew well on denim, but not as well on a T-shirt. First of all, the outlines do not line up. Once again, digitizing gets most of the blame, when the problem is that an embroiderer assumes a given design will embroider well on every fabric. The fact is, it doesn’t. The main point is that digitizing is not always to blame for poor embroidery registration. Problems with a machine, hooping or backing issues, lack of topping and the characteristics of the substrate all can lead to poor registration. The embroidery expert always should assess the situation fully, to discover the actual cause (or set of causes) of poor registration. Don’t blame the digitizer until you are quite sure it is the problem. Whatever the reason, take care of the matter quickly and professionally, then go back to making money! The success of your embroidery business rests on the right supplies. Colman and Company carries a full line of embroidery supplies, as well as everything else you need to make more profits! For any questions, contact ColmanAndCompany.com, or call 800-891-1094.