Do you run a product decoration, personalization, or customization business specializing in hard surface items?

Chances are, you got your start with whatever tools you could get your hands on—maybe some fairly old-school, traditional printing methods that got the job done.

They’ve probably carried you a long way, and that’s something to be proud of.

But here’s the thing: what got you here might not be enough to take you where you’re meant to go next.

That’s where UV/DTF technology steps in.

We bet you’ve come across this term online yourself, spotted it in ads, or maybe even heard it from a colleague.

If it’s flown under your radar and hasn’t caught your attention yet, then you’re in for a treat today.

In this article, we’ll break it all down for you—what UV/DTF is, how it works, and the incredible things you can make with it.

Plus, we’ll show you why investing in our UV/DTF printer might just be the smartest, brightest decision for your business right now.

We’ll even compare it to other methods so you can see how it stacks up against the competition.

Are you ready? Let’s hope so, because this might just change everything for you—and your business.

Introduction to UV DTF Technology

Before we get to the meat of the matter, let’s first take a little history lesson to get everyone on the same page.

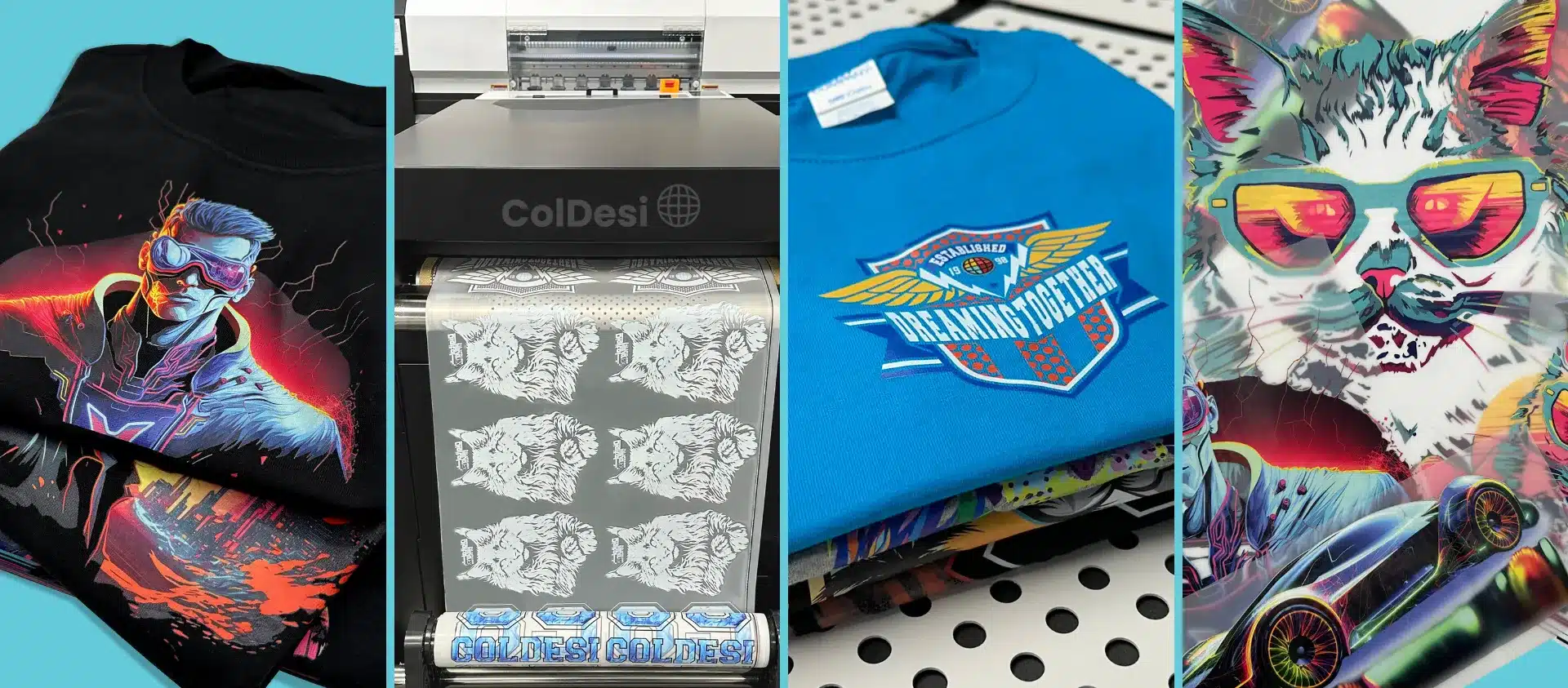

The term ‘DTF’ actually originates from an earlier printing method known as direct-to-film printing. To this day, DTF printers remain one of our most successful products—a favorite among solo decorators and customization businesses!

But we don’t rest on our laurels.

Instead, we sat down and we asked ourselves: “What makes this technology so loved, and how can we push it even further?”

The answer was clear; we need to play on the strengths of both DTF and Ultraviolet (UV) printing. Let’s take the portability and flexibility of DTF transfers and marry it with what UV printing is known for—instant curing.

And voila, by combining DTF’s portability and flexibility with UV’s instant curing, we’ve created something truly new, a multi-purpose UV (ultraviolet) direct-to-film printer.

That’s a short (and oversimplified) explanation about how UV DTF came to be.

Now that we’ve laid the foundation and understand the absolute basics, let’s try to peel back the layers of this technology to see how it works.

How Does a UV DTF Printer Work?

Entrepreneurs and business owners often share a unique ability: the ability to balance a big-picture vision with an eye for detail.

They effortlessly switch between strategic oversight to rolling up their sleeves for hands-on work.

And you’re no exception—you bring the same dedication and precision to everything you do.

Still, the big picture only comes into focus when all the pieces fall into place.

That said, let us help you fill in the gaps by giving you clear information on how ColDesi 24H3R UV/DTF printer works.

The model name 24H3R UV/DTF, gets its name from three main features: number 24 for its 24-inch width, H3 indicating it’s a 3-head printer, and the R at the end telling us that it’s a roll-fed UV printer.

The UV stands for ultraviolet light and is one of the key components in this printer. Finally, the DTF stands for direct-to-film, which means it prints designs directly onto a transfer film instead of on the final product.

The way it works is rather simple: one print head lays down the white ink onto a roll of film (typically a clear carrier sheet that’s later removed), another print head applies the color ink, and the third print head applies the overprint varnish.

Once the ink is printed on the film, it is immediately cured with a UV LED lamp.

Finally, the last step is automatic lamination, which adds incredible durability and provides protection for the decals.

And that’s essentially how the entire printing process works with 24H3R.

But, of course, words can only go so far. To fully understand this technology, watch our supplementary video where we walk you through how it works visually.

By now, your head’s probably spinning, right? Don’t worry—we get it. It’s a lot to take in, but hey, if you’re still here and reading this, you’re going to love what’s coming next.

We’ve put together a list of all the benefits you’ll enjoy the moment this printer makes its way into your workshop.

Benefits of UV DTF Printers

What are the short-term benefits and the long-term advantages of UV/DTF printing?

Well, let’s list them for you and go through them one by one.

Versatility: UV direct-to-film adhesive transfers can be applied to a wide range of uneven, cylindrical or conical surfaces and materials, including but not limited to glass, metal, wood, acrylic, and ceramics.

Durability: The adhesion and durability of these transfers is exceptional. They are long-lasting, scratch-resistant, and colorful!

Portability: These full-color digital prints can be portable in the same way as DTF transfers. This means you can apply them immediately, store them for later use, move them to another part of production, or sell them as wholesale transfers.

Speed: This technology proves to deliver faster and better-quality output than any other technology on the market today.

Cost-Effectiveness: This machine handles all the work for you—no weeding, no masking, no heat pressing. While the initial investment might seem steep, you’ll save money over time with every print and every day you use it. Plus, there’s no need to buy extra equipment like a heat press to apply transfers. One machine does all the labor for you!

Ease of Use: Got employees, partners, or staff who handle the hands-on tasks in your business or workshop? If so, you’ll have no trouble training them to use this new printer—it’s quick and easy to learn!

We could go on and on, but we have the rest of this article to write. The point is, there are even more benefits, features, and advantages than what we’ve mentioned here.

So, we’ll just leave it at that for now.

How about we move on to a few practical and useful applications of UV/DTF printing?

You might also want to read THIS how-to guide to solidify your overall understanding of UV DTF printing. —>

Applications of UV DTF Printing

We’ve saved this section for just the right moment, and that moment is finally here!

If you’ve been following along, by now you know what UV/DTF technology is, how it works, and the benefits it offers.

But there’s still one crucial piece missing—what you can do with it!

This section answers that question.

- Tumblers (Even unique shapes)

- Equipment/Machine Branding

- Promotional products (branded merchandise)

- Glass/Plastic Housing/Covers

- Post-production Labeling

- Automotive Customization

- Glass/Ceramic Ornaments

- Custom Gifts (phone cases, keychains)

- Mugs, glasses, kitchenware

- Awards & Trophies

- Highlighters

- Signage

- + More

That’s quite the list of items you can embellish—and it’s far from complete! If we tried to name every single product, item, or thing you could potentially personalize, customize, or decorate, we’d run out of space.

This is just a small sample of what’s possible.

Other items that come to mind include office supplies, gadgets, USB drives, toolboxes, containers, and a variety of other accessories and miscellaneous goods.

And still, the list goes on. We’re sure you can think of hundreds more!

Next, let’s talk about why businesses should invest in UV DTF printers.

If the earlier points haven’t made it crystal clear, this one will drive the point home.

Why Businesses Should Invest in UV DTF Printers

How can you be sure you’re making the right choice?

Well, let’s lay out a few more reasons why switching to UV DTF printing could be the smartest move for your business right now.

Maybe that will help you make up your mind.

Fulfillment: Customer expectations are higher than ever. We don’t need to tell you that—you’re dealing with it firsthand every day. Production delays and standstills just aren’t acceptable, especially so during peak season or a holiday rush. Clients want their products yesterday! That’s where the ColDesi UV 24H3R comes in. It’s designed to meet (and even exceed) these demands. More on that in a bit, but rest assured: with this machine in your workshop, meeting your deadlines (and fulfilling promises) will be a breeze.

Competitiveness: It’s a competitive world out there, and in business, you’ve got to stay one step ahead of your rivals, no matter what! With a UV DTF printer, you can stay competitive and stay relevant in the current marketplace and keep your business running even during times of uncertainty.

Scalability: A UV DTF printer can easily put you (and your company) on the fast track to success. You’ll be able to grow and expand your business and tap into markets that were previously out of reach.

There you have it—just a few more reasons why your business should consider switching, upgrading, or adding a UV DTF printer to the equipment you already have on-site.

Alright, we’ve covered this printing method from just about every angle. Now it’s time to compare it to other printing methods out there to see how it fares.

How Is UV DTF Printing Different from Standard DTF or UV Flatbed Printing?

We know—at this point you’re probably wondering: “How is UV DTF printing different from everything else out there?”

For years, businesses in the hard-surface printing industry have relied on tried-and-true methods like standard DTF or UV flatbed printing. It’s not about one being better than the other—in fact, each excels in its own way under different conditions and depending on the job.

What’s changed all of a sudden? Why choose UV DTF over all the other options? What does UV DTF work on that other methods can’t quite handle as well?

The answer comes in two parts: the short version and the long one.

The short version is that with this new technology, transfers can be completed in just minutes. Plus, it gives decorators the freedom to apply designs to all kinds of items—different shapes, surfaces, and materials that aren’t always easy to work with.

For those interested in the longer explanation, the secret lies in the combination of advanced UV LED curing and direct-to-film technology.

This pairing gives you the best of both worlds. DTF technology allows for printing vibrant, full-color, highly durable, high-resolution images on film, while UV LED lamps rapidly cure and dry the printed ink.

When combined, these technologies create a new printing process that’s incredibly efficient, productive, cost-effective, and low-maintenance.

And that, ladies and gentlemen, is the innovation and engineering behind the ColDesi 24H3R UV/DTF printer.

Now, show of hands—who’s ready to order it right now? Well, all you need to do is fill out the form below. Once you’ve done that, a product specialist will reach out to talk with you.

During your conversation, you can also request a demo of ColDesi’s UV/DTF printer to see it in action and ask any questions you have before making a purchase.

For a more in-depth look at the differences (and similarities) between UV printing & UV DTF, read this article.