Why Companies Are Replacing their Kornit with DTF Printers?

DTF Printers are the next wave of high-volume printing solutions. For custom t-shirt wholesalers, big brands, and fulfillment houses.

When technology advances there’s always an upheaval in the fashion and apparel markets. At least from a production standpoint.

Like when White Toner Printers like the OKI pro920 and pro8432WT hit the market.

Suddenly, you were able to make short-run, good quality, full-color transfers that you could apply to almost anything. AND you could sell or wholesale the transfers.

All for $10K-$15,000

A great add-on for printers making and selling screenprint transfers because it’s a digital process. No real set costs or quantity limitations.

BUT the perceived quality and feel were not as high. And the cost per print was very high compared to screen printing.

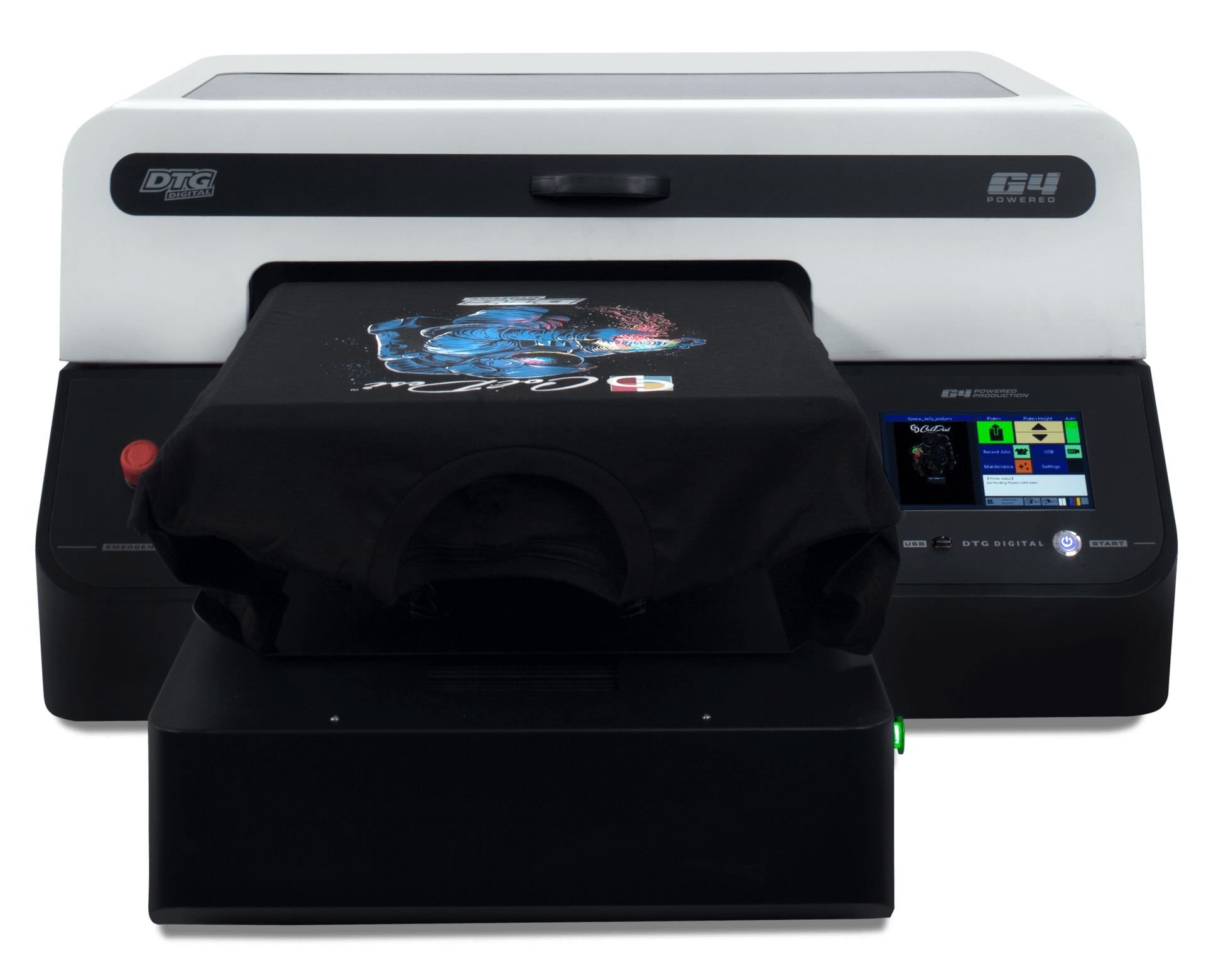

Or when the Kornit and Aeoon high volume direct to garment printers really became productive.

The latest models could deliver very high-volume custom or personalized t-shirts for a competitive price per unit. And they can handle high-volume printing at very good quality.

The feel and cost per print were in-line. They did away with time-consuming and expensive screen printing and screenprint transfers production too.

And direct to garment prints directly onto the material, so the opportunities you get with a transfer printer were lost.

Pricing on those were $15-$25,000. But you’d have to purchase many of them to get the same volume as one of the bigger Kornit DTG Printer models.

The Kornit Printer Boom

Turns out, the biggest custom t-shirt printers, fulfillment shops, custom t-shirt e-commerce operations, and retail brands jumped into the DTG business in a HUGE way. Those brands have so much individual print work that they needed equipment that had a huge throughput.

They jumped to the tune of up to $600,000 or more for each Kornit DTG Printer. Sometimes a LOT more, and multiple units.

And while these Kornit high-volume DTG printers solved many of the problems enumerated above, they came with problems of their own.

Problem 1: Space

The Kornit Atlas, for example, is almost 5,000 lbs is 8’ x 11’ and requires a belt dryer that will take up an additional fifteen to twenty feet of shop space. And that’s space that you have to rent every month to be able to turn over your investment.

While that may be a space saver compared to a screen-printing set-up, it’s still a lot of capital outlay. So, when you consider the consistently tight margins on bulk shirt prints, having to rent all that extra shop space can cause your business plan to dip into the red.

Problem 2: Maintenance and Downtime

One of the things that make Kornit dtg printers so attractive is the built-in pretreat system, and the ability to push lots of ink through the printheads. Literally a ton of ink over time in some of the larger facilities!

And the reality is, the ink manufacturers can’t filter the ink perfectly enough to keep the print heads from clogging up occasionally.

Another maintenance Issue: Kornit printers basically soak the entire garment in pretreat. And that pretreat contains, among other things, SALT.

Salt + Electronics/Metal parts = ISSUES.

Yes, the printhead and other high-volume parts are made to protect against the corrosive effects of the pre-treat, however, the overspray that saturates the air near the interior of the machine affects everything in the area.

Problem 3: Too Many Eggs in a VERY EXPENSIVE Basket

Have you ever watched a business that has too many eggs in one basket? In other words, perhaps they have that one customer that makes up nearly 90% of their overall business? That’s a very risky place to be.

Having only one point of protection for your business is asking for trouble. Sure, you might have dialed in that one customer, or that one type of job down the point where the profits are great. But what happens if the customer goes somewhere else? Your expenses are coming faster than you can recover.

That’s exactly what it’s like to have all your production flowing through ONE EXPENSIVE machine. There’s always the chance that parts will be discontinued, or there could be delays in shipping. You don’t want to have one machine hold up ALL your customers for who knows how long.

The DTF Alternative

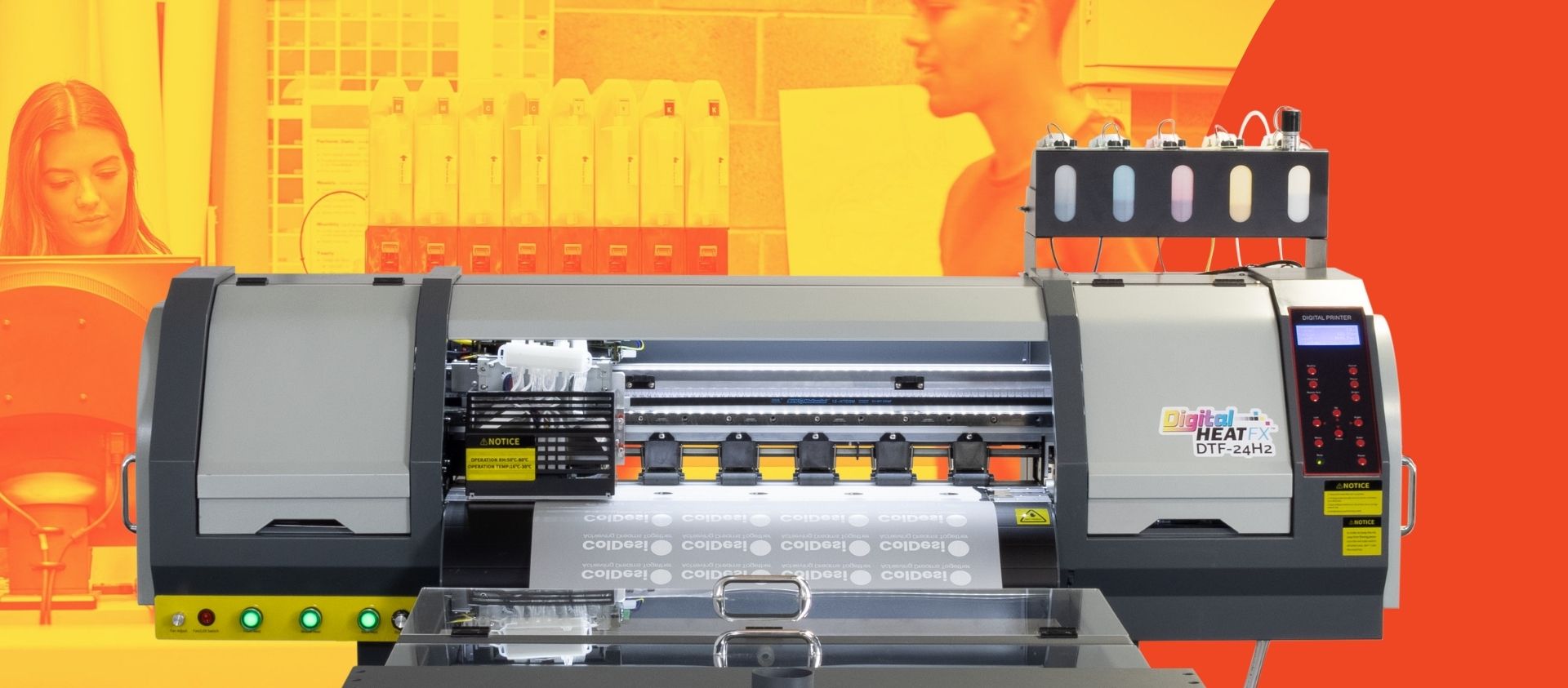

DTF Printers are taking the Kornit and Aeoon shops by storm because of the raw machine output of each DTF Printer.

The process of printing the design is SEPARATE from the process of applying the design!

The bottom line is with DTF, you can print hundreds of design transfers per hour. Beautiful, brilliant color transfers come rolling off the machine without you having to wait for EACH transfer to first be pretreated, and without having to wait for EACH garment to be matched up to the design.

Once one row of transfers is printed, the machine just keeps going directly to the next row. In fact, when printing left chest designs you can print up to 10 or 12 logos across the page at the same time.

The prints flow off the machine in rolls ready to be cut and transferred onto the garments. You don’t have to have one employee operating a single half-million-dollar machine. You can produce work much faster by having an army of assemblers ready to transfer your designs onto garments wherever you need.

Interested in learning more about Digital Transfer Film printers?

Just fill out the form and a professional will contact you.