Speak with an expert. Call 877-458-5575

Let's Compare Avancé Models

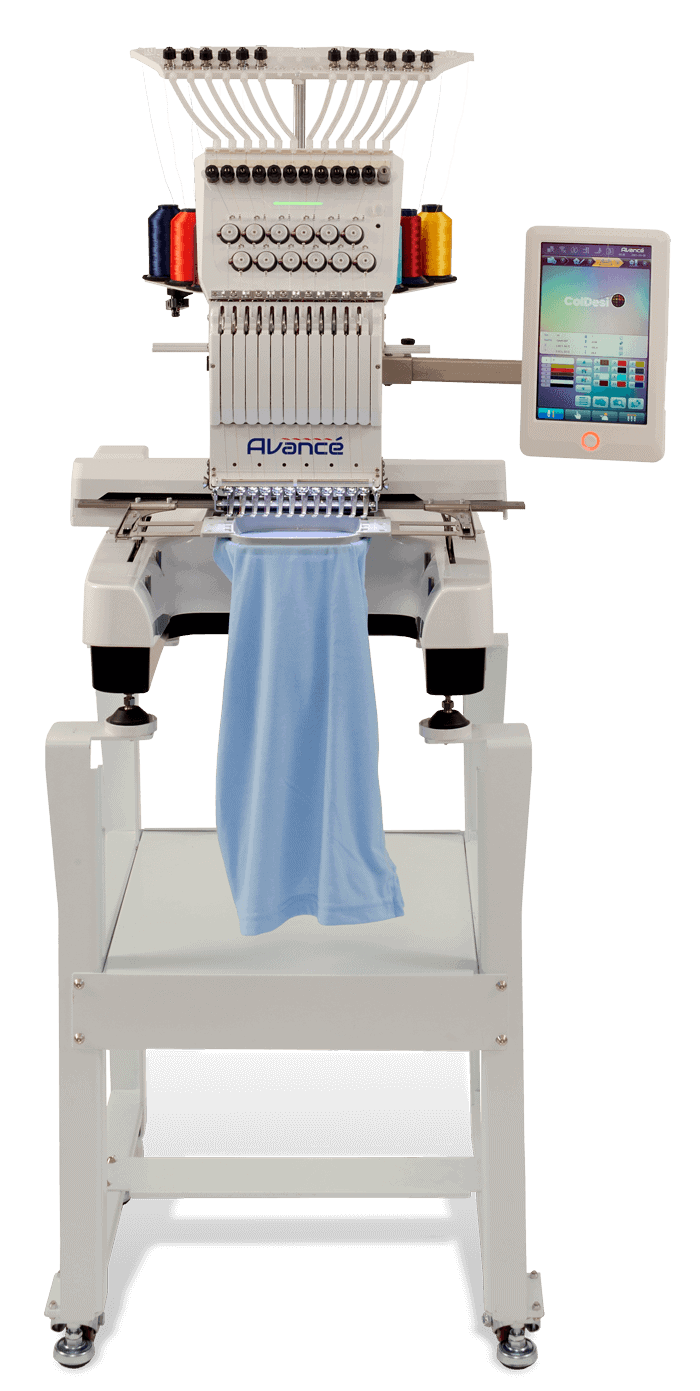

The all new Avance 1201C is an Answer as well as a commercial embroidery machine. It’s an Answer to years of questions and requests from our customers for something smaller, more portable, and easier on the budget.

So here it is! A professional machine that’s reliable, priced well, easy to use and comes with the support of ColDesi behind it.

1201C

- 12 Needles

- 5 Year Warranty

- Portable

Introducing the Avancé 1201C from ColDesi.

- Something more portable – check

- Something smaller for tabletop embroidery — check, check

- Something smaller that's a smaller investment — check, check, check

But while it’s all of those things you’ve been waiting for it’s also something that has the same high quality, same great support, and still has that incredibly new 10.1” touch screen control panel on the side.

CHECK!

This brand new 12 needle COMMERCIAL embroidery machine is perfect for embroidering on caps, flats, polos, jackets, pillows, bags.. even leather.

We’ve tested other embroidery machines with 6,10 and 12 needles and found every single one of them to be lacking. That’s why we took our time to develop the Avancé 1201C – it’s ready if you are!

This single head machine features 12 needles, that big 10.1” touch screen and a great set of supplies and accessories to make sure you get up and running on Day One.

But the first thing you’ll notice when you get your new Avancé 1201C is that it’s been tested by running more than 300,000 stitches before it ever leaves the factory! It’s one of the best-tested monogramming machines in the industry!

FREE Online Training or at ColDesi

FREE Technical Support

FREE Support and Maintenance Videos

FREE FAQs Online

The Avancé 1201C is a 12 needle embroidery machine designed to give you that combination of price, features, and reliability that makes it easy to get into the commercial embroidery business.

No matter what you’ve used embroidery machines for in the past, this single head is for you.

Avancé comes with everything you need to succeed, including a great selection of hoops and accessories a 5year warranty, and the best training in the industry.

It’s FAST – up to 1000 stitches per minute means you can produce the maximum amount of goods in the minimum amount of time.

It’s RELIABLE – before you ever see the Avancé 1201C it has already run 300,000 stitches. That’s how we can offer a SIX YEAR warranty.

It’s READY TO GO – the 1201C is ready to embroider flats and caps right out of the box. It even comes with 4,000 designs to get you started.

- Free Professional Training

- Financing Available

- 5 Year Warranty

- EXCLUSIVE ColDesi+ Rewards

- Complimentary Kickstart Digitizing Services

- FULL Supply Startup Kit including backings, threads +++

- WIFI Connection For Transferring Designs

Avancé 1201C

- Easy-to-Read Full color touch screen control panel – 10.1" Tablet size!

- Built in Fonts for easy monogramming and lettering projects [28 on board fonts]

- HUGE design memory on board - 800 designs or 100 million stitches

- USB Port – Store thousands more designs on a thumb drive

- FAST design load – load your design and start sewing, FAST

- Wifi Enabled – that’s right you can send designs from anywhere on your wifi network

- Maximum speed 1000 SPM

- Thread break detection

- Control precision - min. controllable stitch intervals is .1mm

- Wide Cap Frame - 270 degree

- Super Quiet – perfect for home or retail use

- Real time stitching preview

- Pinpoint laser for perfect embroidery positioning

- Extended light - so you can see what you're sewing

Avancé 1201C

Free Training & 7 Days a week

Support

most popular model

- 12 Needle Commercial Embroidery Machine

- Embroidery Starter Kit

- Free Software

- Free Shipping

- 5 Year Warranty - (ask about extended warranty options)

Packages from $12,600 $9,495 / payments as low as $175/mo

OR

Specifications

| Features | |

|---|---|

| Embroidery Area | 14" x 7.8" (200x360mm) |

| Machine Size | 23" w x 23" d x 63" h (includes metal stand) |

| Weight | 176.37 lbs + stand |

| Needle/Colors | 12 |

| Power | 110V/60Hz and 200V/50Hz self-adaptable worldwide |

| Hoops | 5 Hoops: 3.5”x2.5”, 5.5 x3.5”, 7.5 x5”, 12”x9.5”, and 14”x9 |

| Cap Frame | One |

| Machine Stand | Yes |

| Digital LCD Display | 10.1" Full Color 1280 X 800 Touch Screen |

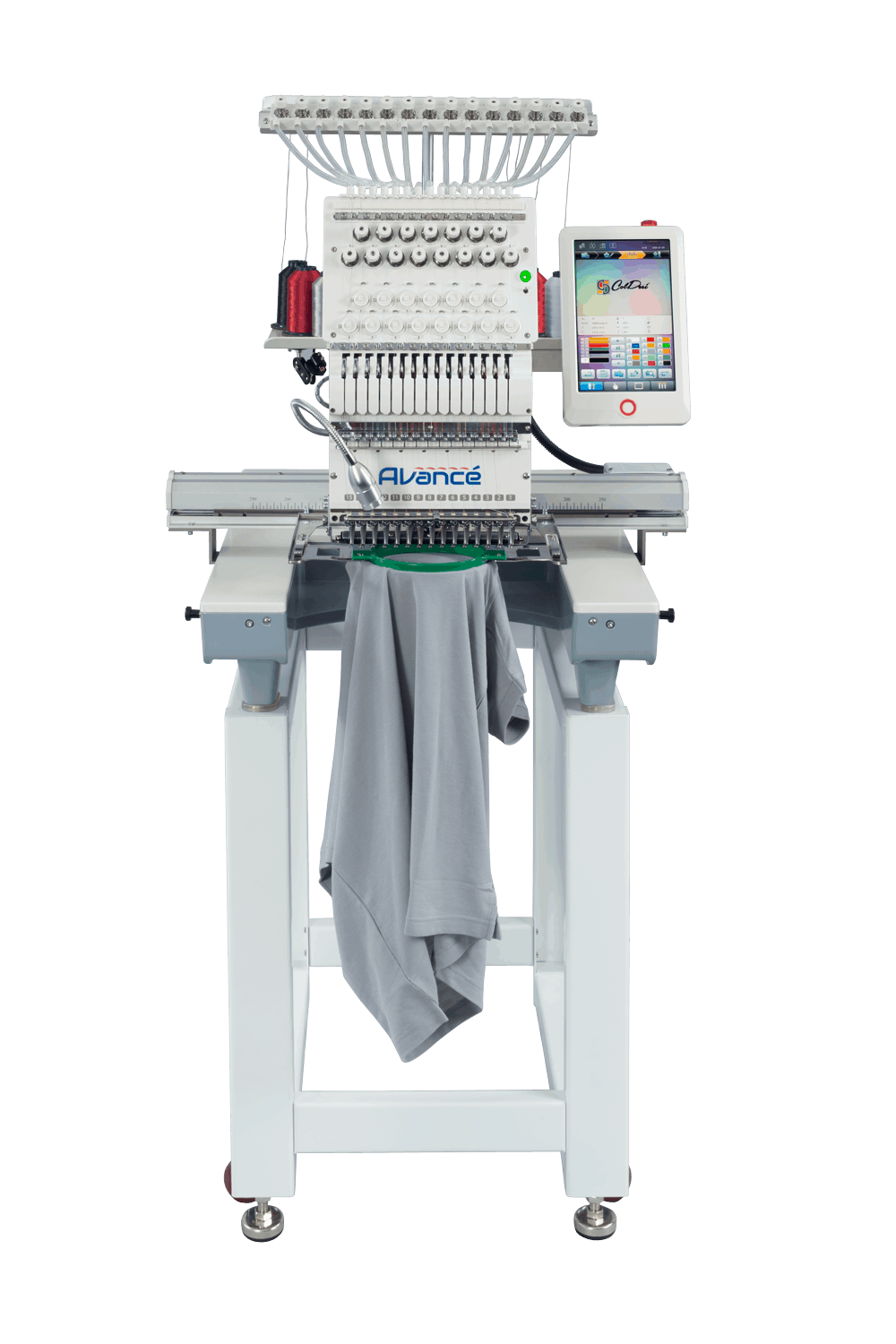

A HUGE embroidery field, more and larger hoops, 15 colors of thread on deck for any job and the commercial components it takes to run a machine all day, every day. That’s what the Avance 1501C from ColDesi has to offer.

Simply say yes to more jobs and get them done faster with this truly industrial embroidery machine!

Now With .

1501C

- 10" Touch Screen

- Advanced Feature Set

- Onboard Lettering

The Avancé comes with what’s most important for your business:

Peace of Mind + Freedom to Create

You’ll get everything you need to succeed including Training on how to use it and the basics of embroidery. You’ll get a great selection of hoops and accessories, a 5-year warranty and the best ongoing support in the business. [And ask about our digitizing software bundles!]

Start Making Money Right Away

Yes – the 1501C is ready to embroider flats and caps right out of the box. You’ll get all the supplies you need to do BOTH

Of course – you CAN do 3D Embroidery. Once you go through our FREE training course you’ll be ready to Puff your next design!

Included designs? Definitely. You get 4,000 embroidery designs to get you started.

And there are on board fonts. And you get 2 of every hoop + and oversized border frame.

Avancé 1501C

Free Training & 7 Days a week

Support

most popular model

- 15 Needle Commercial Embroidery Machine

- Embroidery Starter Kit

- Free Software

- Free Shipping

- 5 Year Warranty - (ask about extended warranty options)

Packages from $14,760 $11,495 / payments as low as $205/mo

OR

Specifications

| Features | |

|---|---|

| Embroidery Area | 22" x 14" (560mm x 360mm) |

| Machine Size | 33" w x 30" d x 63" h (includes metal stand) |

| Weight | 197 lbs + stand |

| Needle/Colors | 15 |

| Power | 110V/60Hz and 200V/50Hz self-adaptable worldwide |

| Jacketback Hoops |

53 x 35 cm (21" x 14") includes hoop and table Also 14" x 20" Frame for large items |

| Large Tubular Hoops | 30 x 30 cm (12" x 12") |

| Round Hoops | (2 each) 21 cm (8.6"), 15 cm (5.9"), 12 cm (4.7") and 9 cm (3.5") |

| Digital LCD Display | 10.1" Full Color 1280 X 800 Touch Screen |

Avancé 1501C

- Free Professional Training

- Financing Available

- 5 Year Warranty

- EXCLUSIVE ColDesi+ Rewards

- Complimentary Kickstart Digitizing Services

- FULL Supply Startup Kit including backings, threads +++

- WIFI Connection For Transferring Designs

- Full color touch screen control panel - makes it so simple to use!

- 28 on board fonts for easy monogramming and lettering projects

- HUGE design memory on board - 800 designs or 100 million stitches

- 10.1" Full color, high resolution touch screen interface

- USB Port - Convenient design load

- FAST design load - saves production time

- Network Ready - load designs from anywhere

- Maximum speed 1200 SPM

- Thread break detection

- Control precision - min. controllable stitch intervals is .1mm

- Wide Cap Frame - 270 degree

- Quiet Operation! - quieter than our previous model

- Real time stitching preview

- Pinpoint laser for perfect embroidery positioning

- Extended light - so you can see what you're sewing

Amazing Training

World-Class Support

Financing Option You Asked For

We’ve helped 31,000+ people start and expand their business with an embroidery machine. Will you be 31,001?

Build your dream business in 3 simple steps:

Step One

Fill out the contact form or give us a call. We love questions!

Get StartedStep Two

We’ll answer all your questions & give you a custom quote.

Get StartedStep Three

Focus on your business knowing you’ve made the right decision.

Get StartedReady to get started? Simply fill out the form below.

Call 877-458-5575 or Chat below.

We believe in privacy and communicating in the best way for your business. By completing the above form, you agree to be contacted by ColDesi Inc through phone calls, emails, and text messages. You can opt-out of emails with unsubscribe links or opt-out of texts by replying STOP at any time.