DTG Printers are the best way to print directly on t-shirts. Gone are the days of burning screens and manual color changes.

With a digital direct-to-garment printer you just press print!

DTG Printing is the perfect solution to vinyl users who are ready to take the next step or those in the promotional product market looking to add t-shirts.

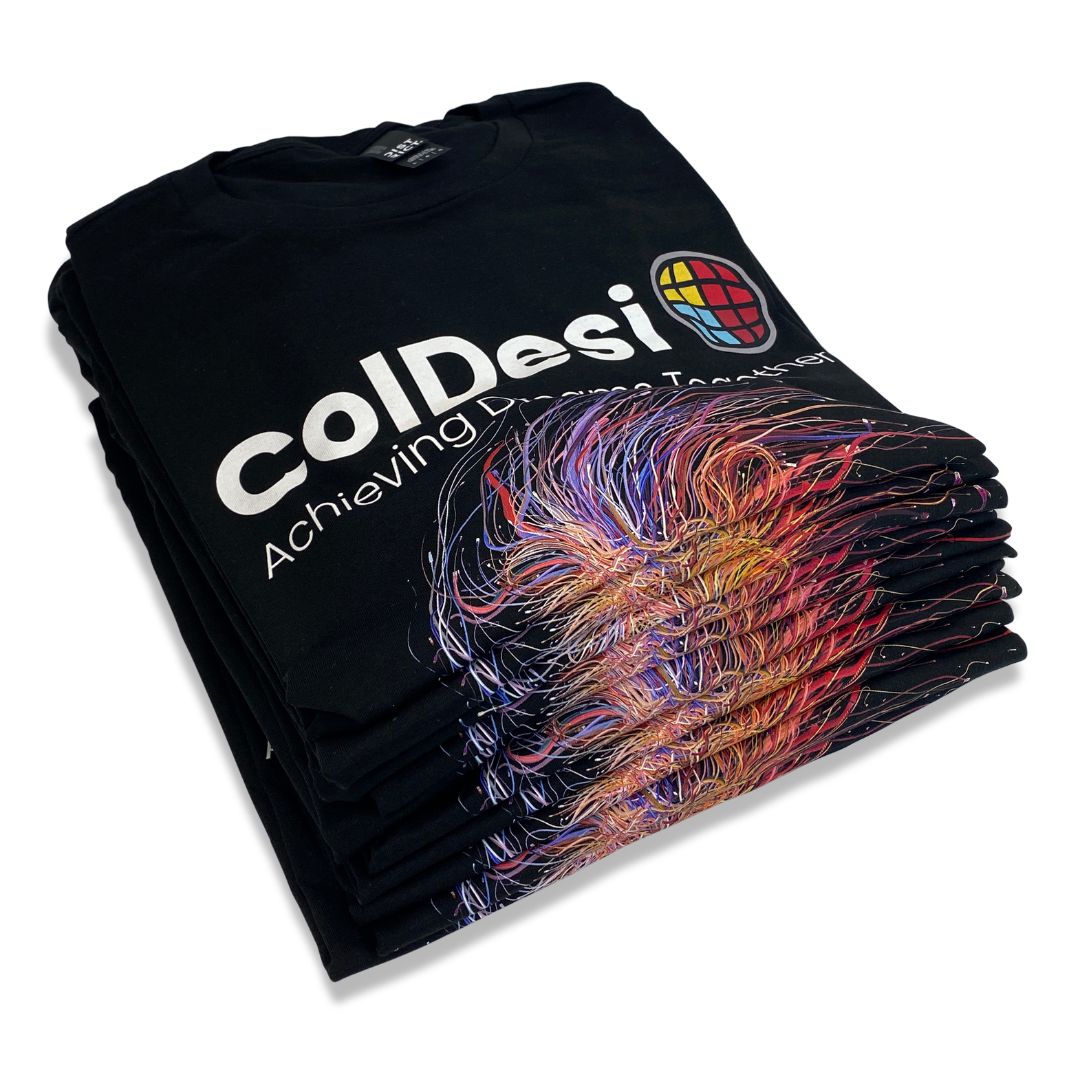

Decorated t-shirts are always a hot seller for special events, holidays, family events and more! Plus, you can even print on pillowcases, tote bags, canvas and more with DTG Printing.

Here are the top four reason why you need to get a DTG Printer… like yesterday!

#1 - Print custom designs on-demand

With a DTG Printer you don’t have to set up screens or worry about color changes! You can load up your favorite designs and just press print. That’s the beauty of digital printing.

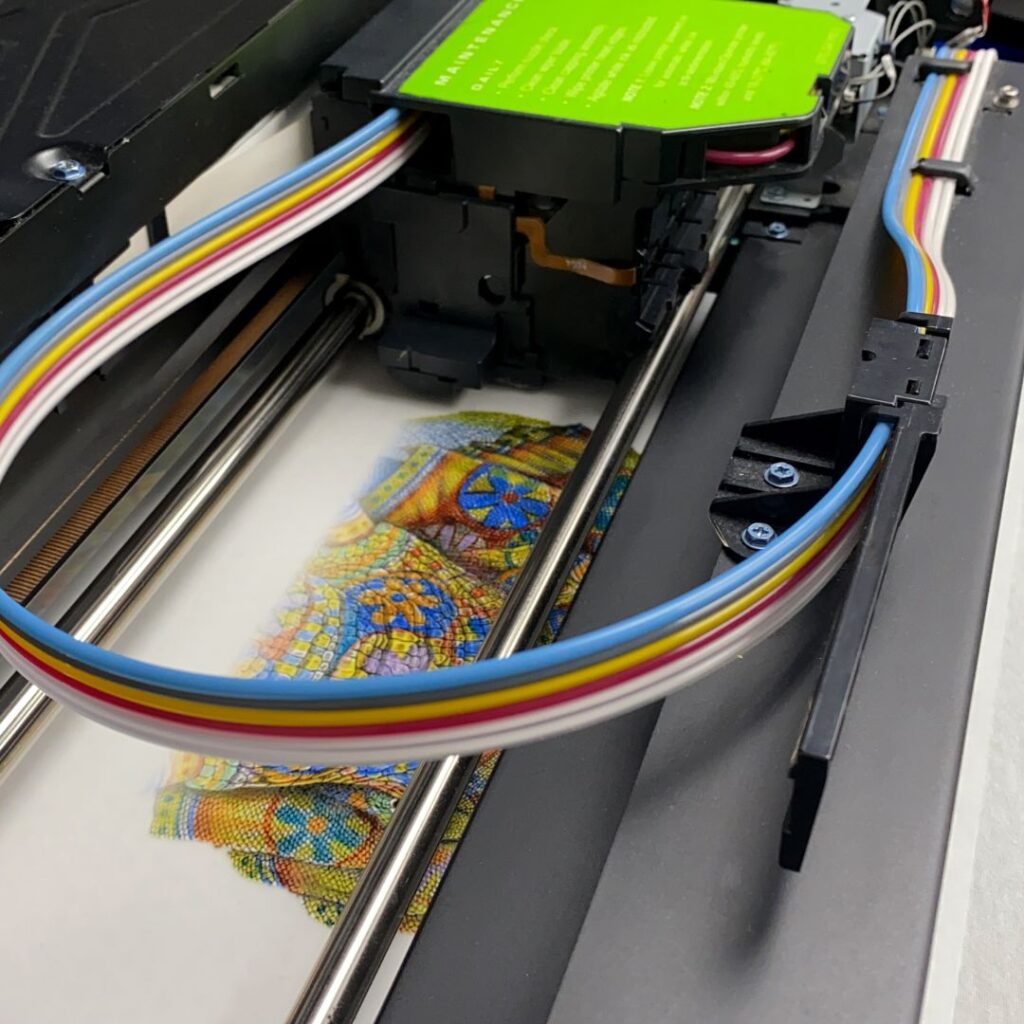

Here is how DTG Printing Works

1. Users create designs in software like Adobe Photoshop or they purchase art that’s already made.

2. Designs can be sent to the DTG G4 from the computer or you can upload them directly on the machine with a flash drive.

3. Next you will pre-treat your garment. Pre-treatment solution is like a glue that allows the ink to stick to the fabric. Then dry the pre-treat with a heat press.

4. With the DTG G4, users don’t have to “hoop” their shirt like with traditional direct-to-garment printers. The patented vacuum platen allows you to lay your shirt on top and let the vacuum platen pull it into place.

5. Now you can select your design on the touch-screen control panel and press print!

6. The last step in DTG Printing is to dry the ink. A quick heat pressing will cure the design so it’s ready to be sold and worn.

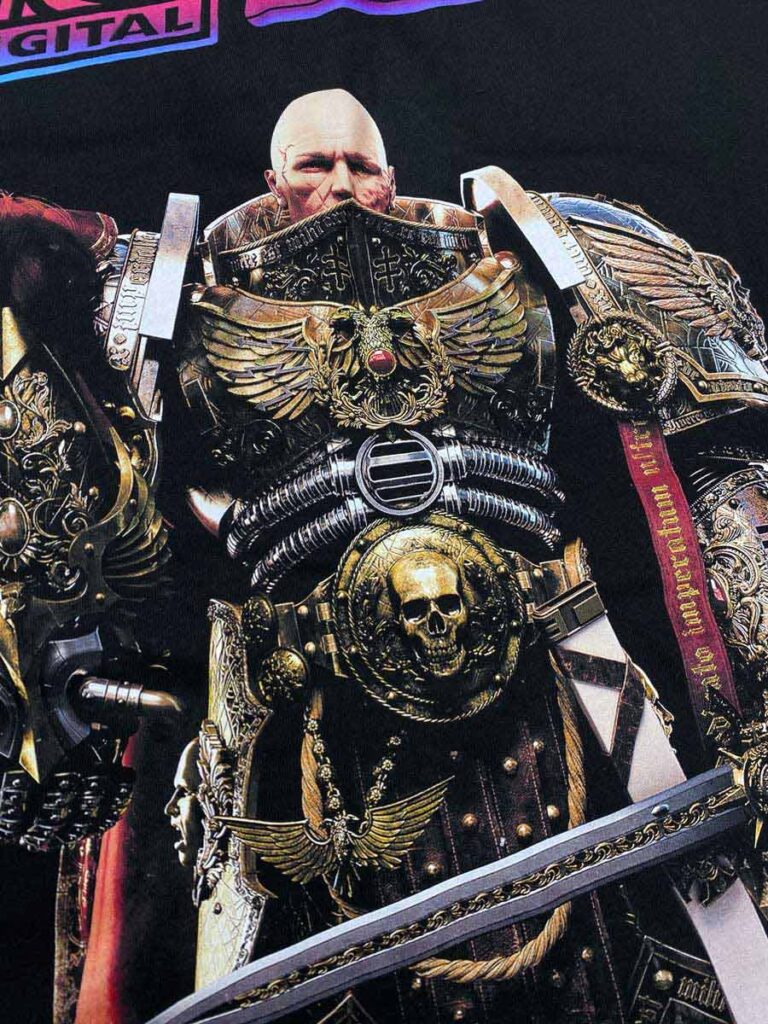

#2 - Vibrant Prints - Amazing quality photos

DTG Printers are known for their vibrant inks and print quality. You can put photos and portraits on t-shirts with this system. This is great for memorial and reunion shirts.

The DTG G4 uses Kodak Inks, and the vacuum platen sucks all the ink into the fabric. This creates super rich colors.

When printing on colored or dark garments, the machine will print a layer of bright white ink first. Then, it prints color on top.

Kodak’s KODACOLOR fabric ink features an exceptionally large color gamut, a more reliable high-quality image with outstanding shelf life and a soft, natural feel, as well as better in-printer performance.

#3 - Hand Feel

DTG prints are ultra-soft. Because they are printed directly on the shirt and there is no transfer or something laying on top of the garment it almost feels like the design is not there.

The feel is most similar to sublimation and nowhere near as heavy as vinyl, white toner or DTF transfers.

The Vacuum platen also plays a part in the soft hand feel because the ink is really soaking into the fibers of the shirt.

#4 - Washability & Stretchability

The washability of shirts printed with the DTG G4 is unmatched. A design on a 100% cotton tee can outlast the life of the shirt. Plus, you can stretch it and the print won’t crack!

The graphic’s ink is embedded into the shirt fibers. After heat pressing and curing the ink, your design will have amazing adhesion.

The DTG G4 has taken traditional direct-to-garment printing and turned it into a revolutionary printing process with modern technology.

Features Of The DTG G4 include:

- Touchscreen control panel

- Onboard print memory

- Vacuum Platen

- Kodacolor Inks

- Reduced maintenance

- Increased print speed