Similarities | Flatbed UV Printing Mechanics

Both DTG printers and Flatbed UV printers are inkjet printers.

They use print heads that traverse over a substrate depositing ink onto it. The item being printed is positioned on a bed that either transits under the scanning print head gantry or is traversed by the print head gantry.

Basically that means that either the print head moves over the top of the item being printed or the item is moved underneath the print head to create the image.

Smaller UV printers and DTG printers transit the material under the head as opposed to moving the head over the material. But there are a few exceptions.

Most DTG and small to mid-format UV printers are considered flatbed uv printers.

This means that they have a limited print area and work with specific materials that are loaded onto the bed – not fed by a roll like large format sign and sublimation printers.

That’s an important distinction. We’re discussing flatbed UV printers and typical DTG printers where you typically load an object(s) onto a “flat bed”, as opposed to a roll printer that prints on a roll of material that is unwound and passed under the print head.

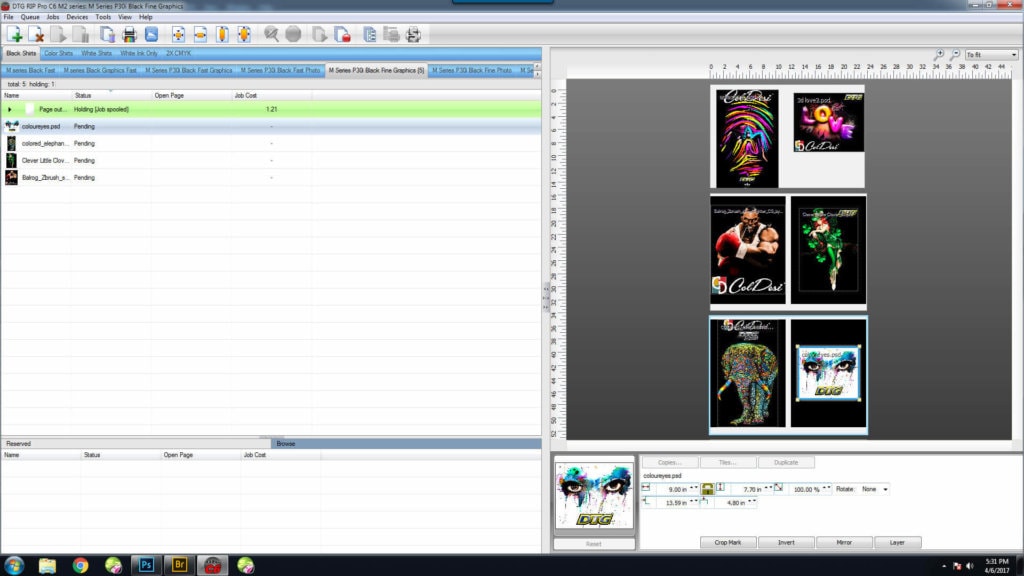

Similarities | RIP Software

Software for DTG and flatbed UV printers is very similar.

Both of these types of printers are traditionally driven by RIP software (Raster Image Processing software) that helps separate out layers for the printer, manages color, resolution, print quality and other important functions.

Many of these RIPs also calculate ink costs as well as allow for barcode automation and printed image archiving.

The RIP software included with all of the DTG and UV printers here at ColDesi are the same software with slight variations in the queues to account for the materials being printed, layering and templating.

Similarities | Printing with White Ink

Most DTG and flatbed UV printers are equipped with white ink so that they are able to print on substrates that are not white and maintain color integrity.

This is in contrast to a sublimation process, for example, that requires you print on or apply the result to a light colored or white material.

White ink is used when printing on a black t-shirt (DTG), for example, because if you applied yellow ink to a black background you’d get a very dingy result. If you put down a layer of white ink, that same yellow would show up as the color you intended.]

Use of white ink is important as both DTG and flatbed UV printers are most frequently printing on to finished products – whether garments for the DTG or cell phone cases, tiles, pens … etc. for the flatbed UV printers.

Similarities | Working with Substrates

Another way that the printers and processes are similar is the way we handle items we print.

DTG Printers

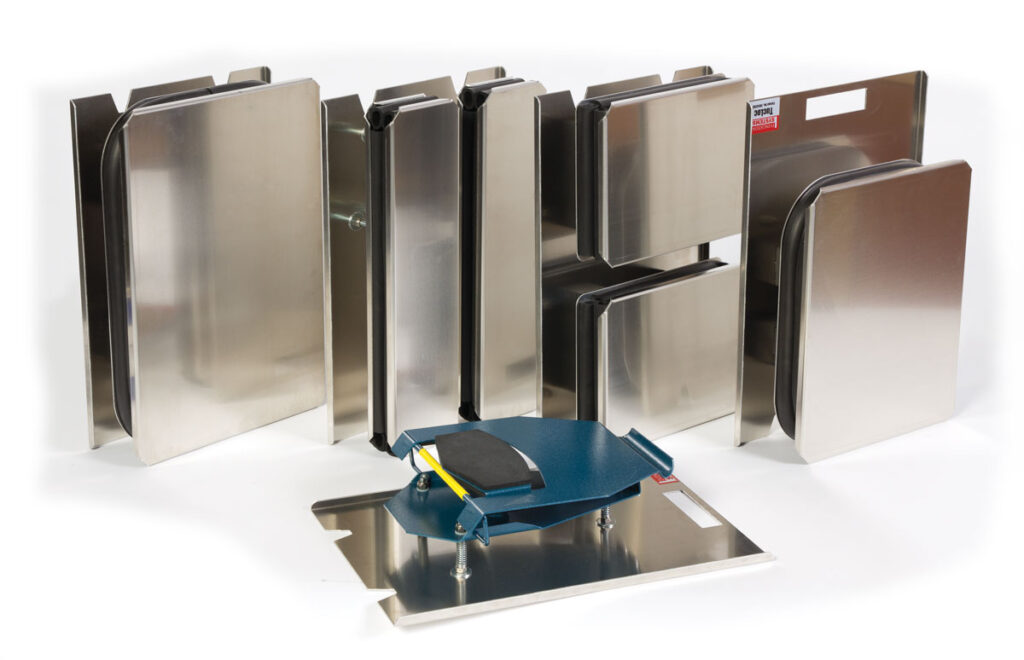

On DTG printers we use platens to hold our garments in a specific position on the print bed to be able to consistently print to the same spot on the garment.

The platen is drawn into the printer, then the ink is applied. Similar to a home inkjet printer drawing a piece of paper in before printing.

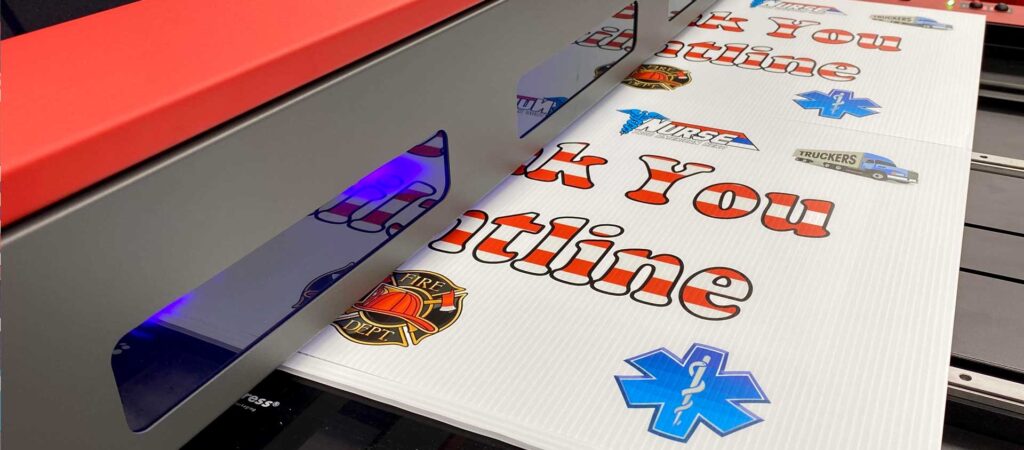

Flatbed UV Printers

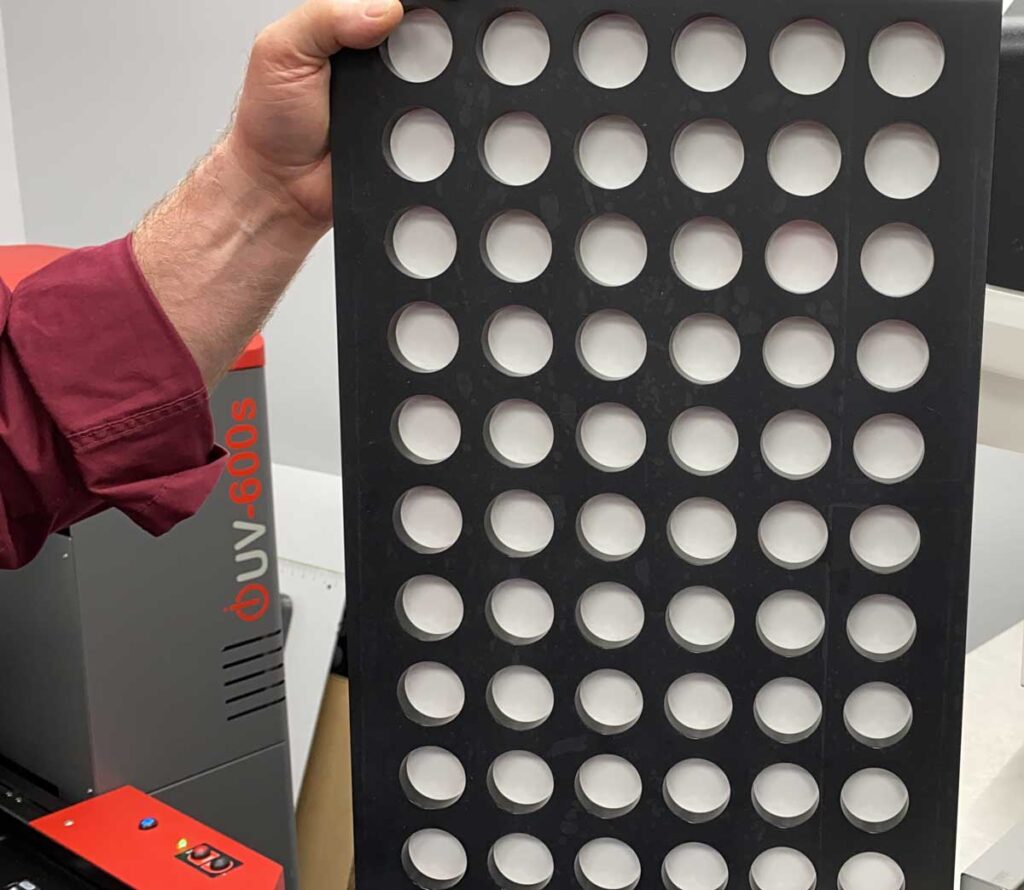

In the UV printing world we use jigs to hold items, especially items where we may be printing multiples at one time (think golf balls, poker chips, USB thumbdrives etc.).

These jigs are often removeable from the printer so one can be unloaded and reloaded while another is printing.

Similarities | Preparing to Print

The idea behind pretreatment of substrates prior to printing is the last similarity we’ll discuss.

This is an area where there are both similarities and differences.

A direct to garment printer requires a pretreatment to be applied to the substrate (shirt) prior to printing. This pretreatment helps to keep the ink on or nearer to the surface and also improves ink adhesion to the shirt.

It also causes the white ink to “crash” and form a layer for the color inks to set on when printing on dark shirts.

Likewise, some substrates printed on flatbed UV printers require a “pretreatment”, referred to as an adhesion promoter. UV inks adhere to substrates mainly based on the surface tension of the material being printed. The higher the surface tension, the better the adhesion. Adhesion promoters require lower surface tension than the ink does while also offering a “print friendly” finish when dried. When looked at from this perspective they are similar to DTG pretreatments.

The difference here is that not all substrates require adhesion promoter and the materials that do may require different adhesion promoters or in other words glass requires different adhesion promoters than plastics or metals and vice-versa.

About Vacuum Beds

Before 2020 this would have appeared in the Differences section, not the Similarities.

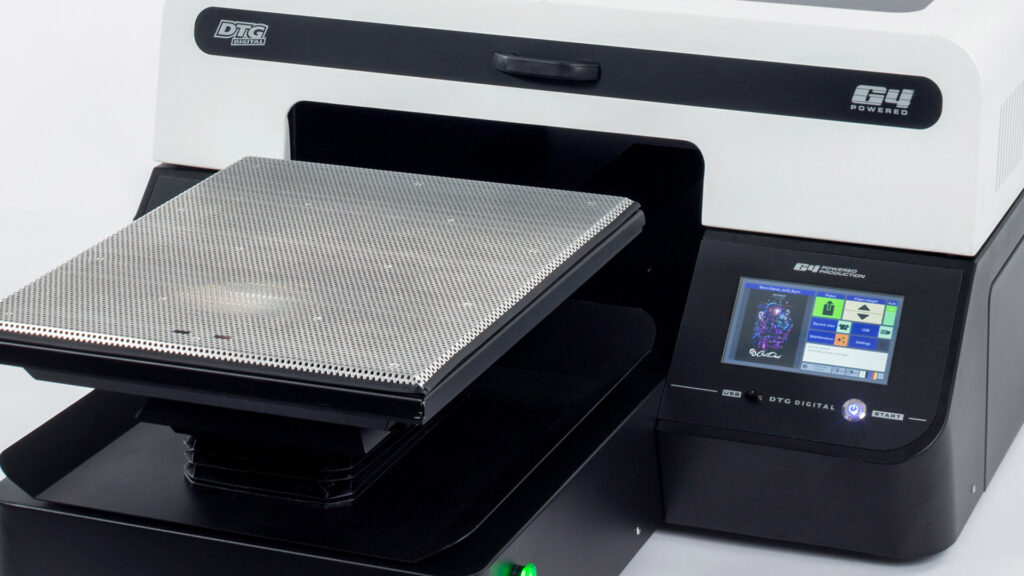

But with the advent of the G4 direct to garment printer and the patented vacuum platen that comes with it, that has changed!

A vacuum bed is a platen or table as described above, but it’s perforated and uses a pump or fans to draw the material flat and keep it in place.

Vacuum bed

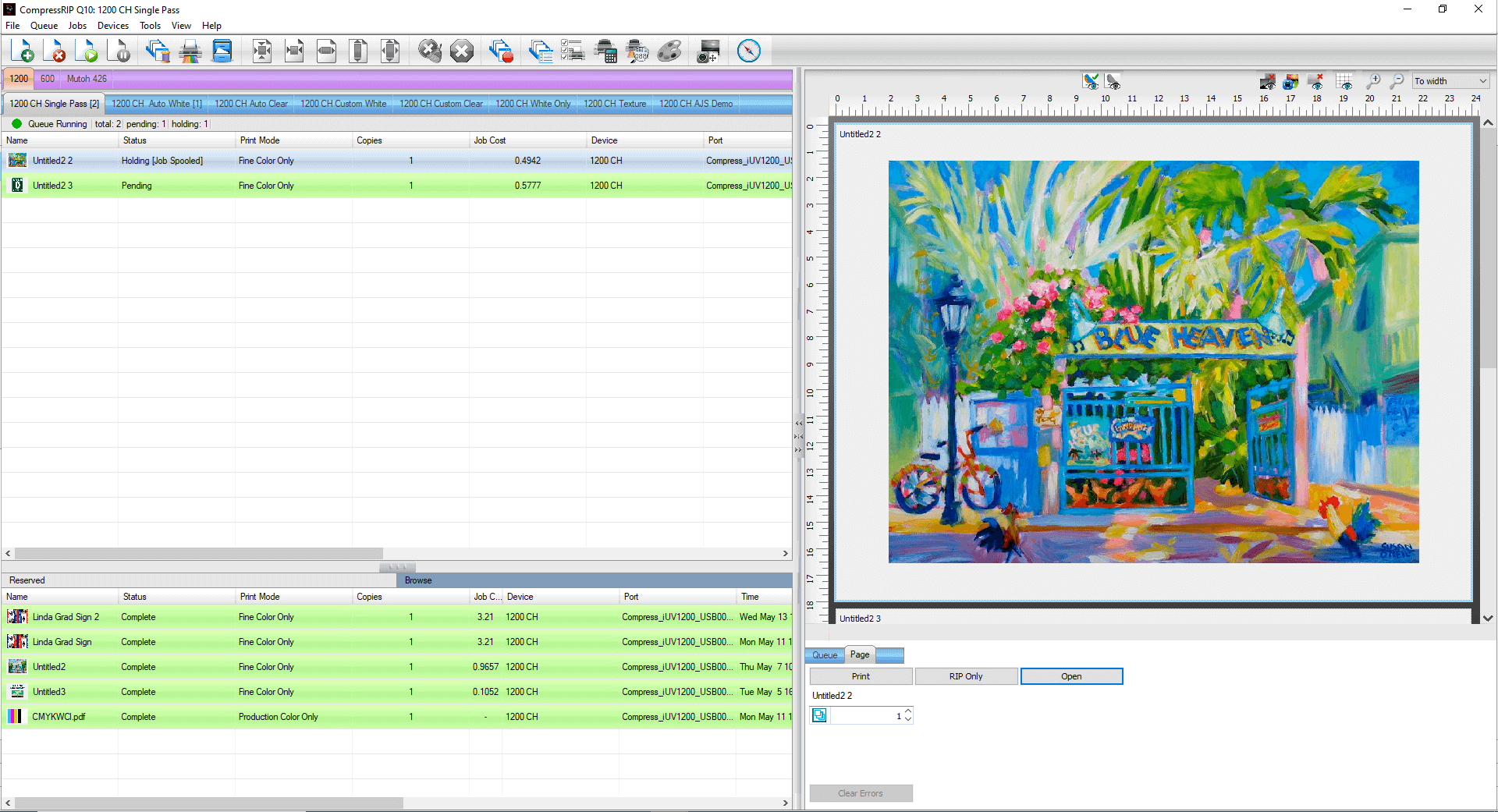

The vacuum BED on a flatbed UV printer is designed to hold items in place while the bed moves. This is very important if you’re dealing with a very thin substrate, like paper or fabric. It’s also very important for items that are not exactly flat or may curl.

For example, if you’re printing on an unfolded box for packaging the cardboard will probably try to pop up on one end or another, like in this video:

That video is of the Compress iUV1200s vacuum bed, but Mutoh’s Xpertjet flatbed UV printers also employ vacuum beds.

The alternative is to use a sticky matt that works just as it sounds.

Vacuum platen

Before the advent of the G4 DTG printer, the only options for getting a blank t-shirt to remain still on a platen were to use spray or roll on tack, a frame/ring or by tucking the garment into a holding mechanism.

Tuc-loc platens have you doing just that. You load a t-shirt onto a platen, and then tuck into rubber gaskets that run all around the edge. Many printer manufactures use Tuc-loc platens.

Sticky platens are used by DTG printer manufacturers like Epson, Ricoh and Brother. The problem with sticky is that it eventually wears off AND makes rearranging a misplaced shirt a “sticky” situation.

The Vacuum Platen used on the G4 DTG Printer is designed not just to hold the shirt in place, that vacuum also reduced overspray by sucking more of the ink jetting from the heads into the shirt instead of into the air. Less ink mist means less maintenance on the printer and less likelihood of a printhead clog.

Also, super easy to adjust a misplaced shirt.

Now that we know the similarities between DTG and UV printers let’s look at the differences.

Flatbed UV Printers and DTG Differences

There are three major differences in the two types of printers.

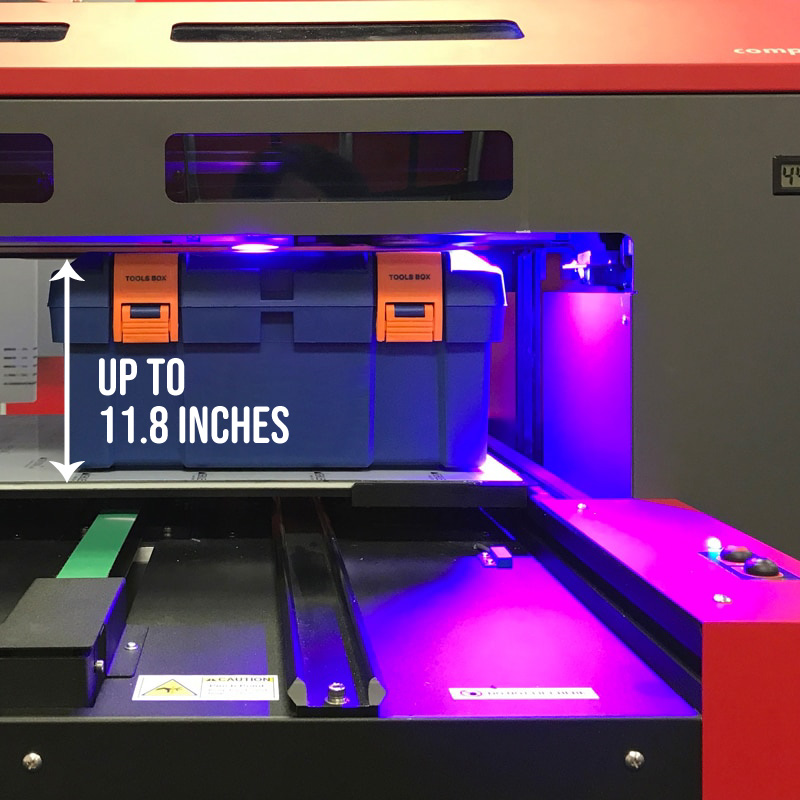

#1: Depth of Print

Print DEPTH is surprising important. Most DTG printers are only a couple of inches deep from the lowest position of the print bed (or pallet on a DTG) to the print head.

This limits the depth of items you can print on to about 2 inches.

Two inches is more than enough for printing on almost any textile – tshirts, jackets, canvas bags, canvas’s for photos. All less than 2” thick.

With an UV printer, depths range from about 3 inches up to almost a foot.

The greater depth of the UV printer allow for a wider range of pre-assembled items.

For example the Mutoh 426UF has a 2.75” depth, so can print golf balls, etc., but the Mutoh Xpertjet flatbed uv printer (s) have up to a 5.91” depth and the Compress UV Printer series can handle printing a basketball with its 11.8” depth.

Depth of field, even if you can customize a basketball or a cylindrical item like a travel cup, does not mean it’s not still a FLATBED UV Printer.

#2: UV Inks vs DTG Inks

UV printers use UV (ultraviolet) light to cure the inks in the printer.

When the object emerges from the printer the inks are dry and ready to deliver.

On DTG printers the inks are wet and need to be dried with a heat press, tunnel or box dryer. Which leads us to the final major difference – inks.

As mentioned above the UV inks are cured by ultraviolet light and DTG inks are cured by heat (heat press, tunnel or box dryers).

Why the difference?

DTG inks are water based and contain polymers that are activated by heat which “set” the inks into the fabric that is being printed on.

Water based inks can lose as much as 40% of their volume due to this process. So you generally need to use more ink than you would if there was no volume loss due to the evaporation of the water in the ink.

UV inks cure by a photochemical process. These inks are made of liquid monomers and oligomers and not water based.

#3 Curing the Ink

Curing means drying and/or hardening of the ink.

Think about how the properties of a wall you paint change as the paint dries and becomes more rigid. UV and DTG inks both have to be cured – but in very different ways.

UV Ink

When the inks are exposed to UV light chemicals called photoinitiators in the ink become “excited” and cause the monomers and oligomers to polymerize (become polymers) hardening or drying.

So when the substrate is printed on with the ink jets in the print head, a UV light is shined on the liquid ink and dried almost in real time.

When you print comes out of a flatbed UV printer – it’s ready for use.

DTG Ink

When a freshly printed shirt comes out of a DTG printer – that ink is WET.

And if you touch it, or fold the fabric accidentally before it’s cured you have ruined the garment.

DTG ink must be cured with either heat, or head and pressure. Some larger print shops will use a tunnel dryer – basically a large pizza oven – that runs at a high enough temperature to fuse the inks into the fabric.

But most direct to garment print shops use a heat press that applies both heat and direct pressure to set the ink in place.

Once this process is complete you have a very durable finished product.

Because of the curing differences you’ll use less ink printing an image on a UV printer than you will on direct to garment printer

Flatbed UV Printers and DTG Printers – Digital Cousins

So, there you have it. The similarities and differences between DTG and UV printers.

What is nice about them is that while they perform very different duties in the printing world, they are surprisingly similar in the way they operate and the software they use.

This makes it very easy to add one once you have the other – the learning curve is shortened. And therein lies the real benefit and the greatest opportunity.

You are already dealing with artwork for your customers, you are using RIP software to drive your printers (in some cases the exact same software and RIP) meanwhile your customers are probably purchasing items that you do not offer (think t-shirts for the UV folks and ad specialties and signs for the t-shirt folks) USING THE SAME ARTWORK.

Why not bring that business in house, capture the revenues that are going elsewhere and make it easier on your customers? Sounds like a win, win!