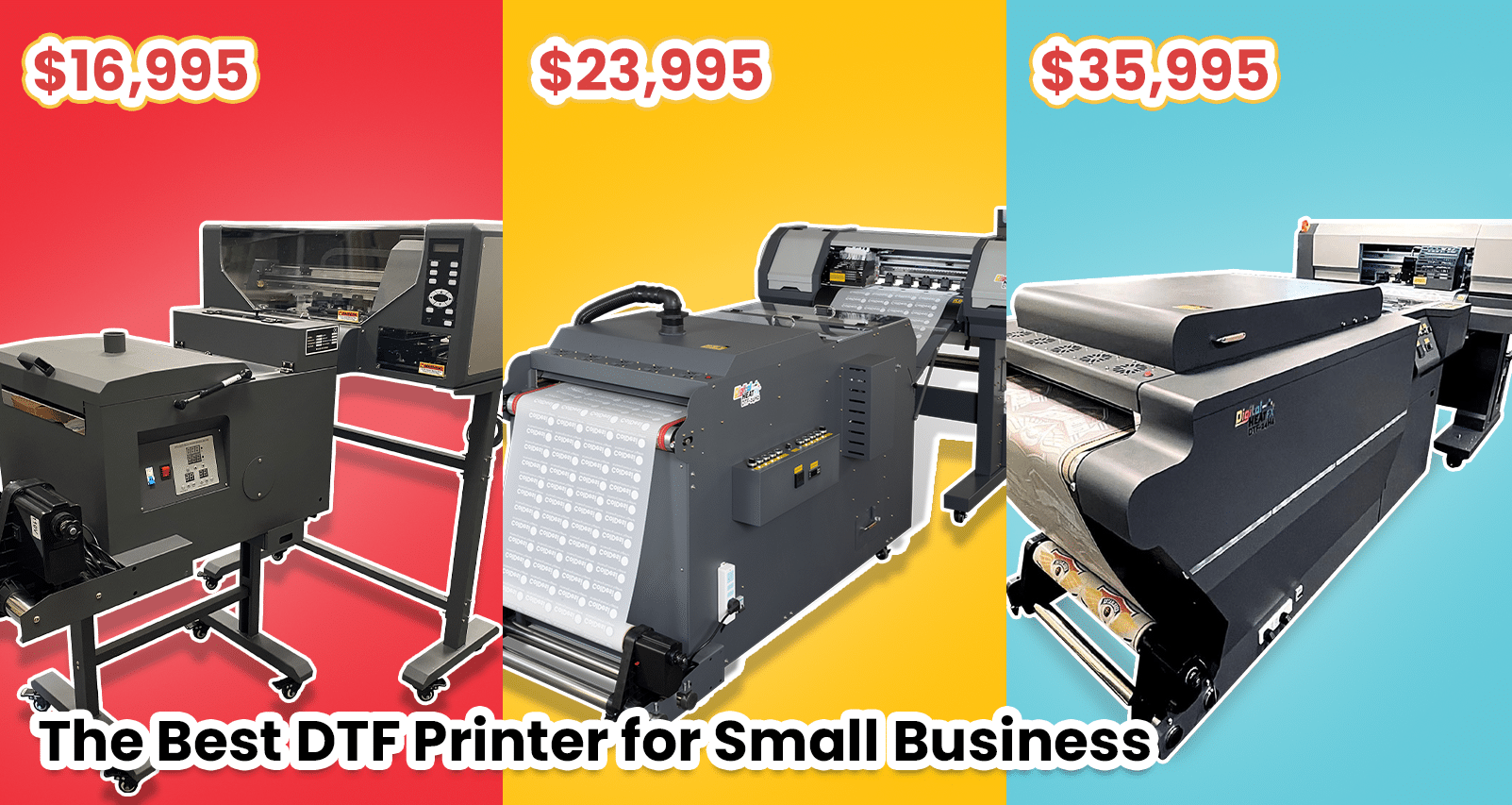

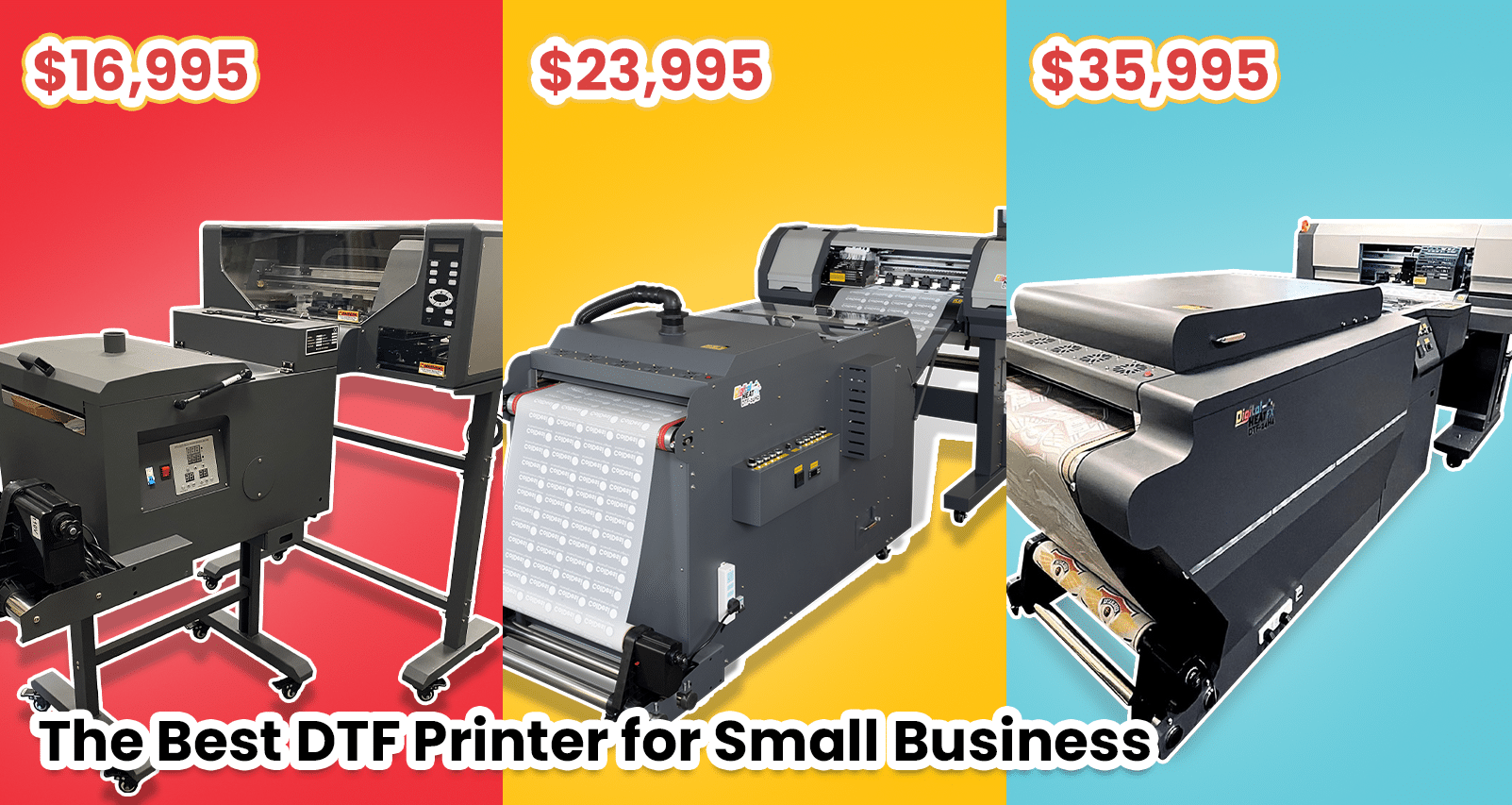

The Best DTF Printer for Small Business

If you’ve come to this page for answers to: ‘’Which is the best DTF printer for small business?”, then you’ve come to the right place!

If you’ve come to this page for answers to: ‘’Which is the best DTF printer for small business?”, then you’ve come to the right place!

See ColDesi’s customization equipment in action! Fill out this form for an online demo with a pro, Or call 877-793-3278 or chat below!

Do It Yourself Custom Home Décor is all the rage these days. People are looking for ways to add their own personal touch to their

What is a Roll Slitting A roll slitting machine can convert rolls to sheets and cuts larger rolls into smaller, custom sizes. With our advanced,

© 2024 ColDesi Incorporated. All rights reserved